Purifying equipment and purifying method for purifying catalytic cracking slurry oil

A technology of catalytic cracking oil slurry and purification equipment, which is applied in the petroleum industry, refining hydrocarbon oil, refining with the help of centrifugal force, etc., to achieve the effect of reducing the amount of centrifugal treatment, improving efficiency, and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

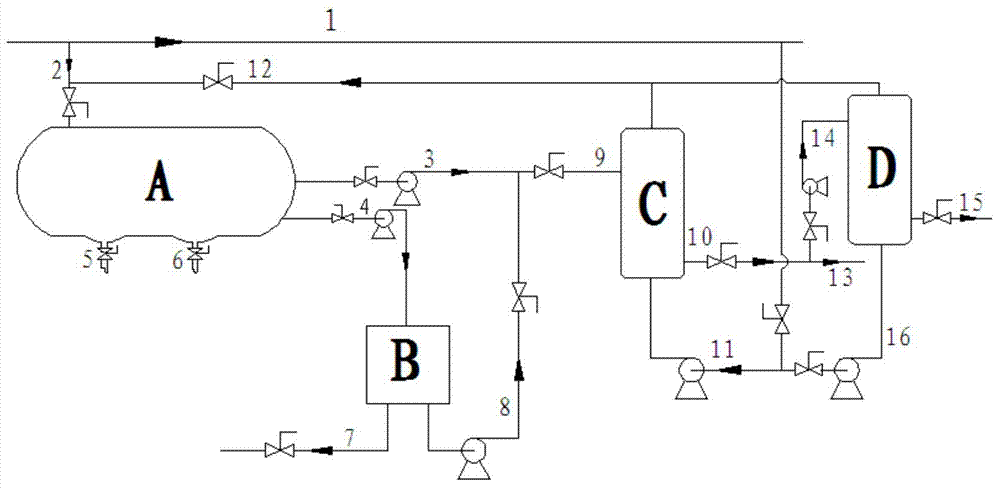

[0031]The heavy oil catalytic cracking oil slurry produced by a refinery contains 4.2g / L solid particles (GB / T511-2010). The oil slurry was settled in the settling tank for 12 hours at a settling temperature of 230°C. The content is 0.87g / L, the average solid content of the bottom flow of the settling tank is 9.1g / L, the bottom flow is sent to the centrifuge, the operating temperature of the centrifuge is 200°C, the centrifugal force of the continuous centrifuge is 6500G, and the semi-refined oil The solid content of the slurry is 0.92g / L. The oil slurry overflowed from the settling tank and centrifuged and semi-refined is sent to the first-stage electrostatic separator at the same time. The electrostatic voltage is 20kV, the temperature is 170°C, and the relative residence time is 10min (oil slurry The relative time of flowing through the separator filler), the solid content in the refined oil slurry after the first-stage electrostatic separation is 0.095g / L, and the desolidif...

Embodiment 2

[0042] The purified oil slurry of the primary electrostatic separator in Example 1 is directly sent into the secondary electrostatic separator. The electrostatic voltage of the secondary electrostatic separation is 35kV, the temperature is 160°C, and the relative residence time is 10min. After the secondary electrostatic separation The solid content in the refined oil slurry is further reduced to 0.008g / L, the total desolidification efficiency can reach 99.81%, and the recovery rate of the heavy oil slurry is still as high as 88%, which can meet the requirements of the solid content of raw materials for carbon fiber products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com