A method for improving the stability of sapo-34 molecular sieve membrane in water vapor environment

A technology of SAPO-34 and molecular sieve, applied in chemical instruments and methods, membranes, membrane technology, etc., to achieve the effect of improving separation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1, the SAPO-34 molecular sieve membrane was placed in an oven and dried at 100 °C for 2 h.

[0027] Step 2, after mixing n-dodecyltrimethoxysilane and n-octane evenly at a volume ratio of 1:50, seal both ends of the film and put it into it. Specifically, use polytetrafluoroethylene tape to seal both ends of the film Seal it and fix it with a bracket to prevent the grafting solution from entering the cavity of the hollow fiber to block the pores of the support. Finally, put it into a stainless steel reactor for hydrothermal treatment and heat at 110 °C for 6 h.

[0028] Step 3, after the grafted membrane was washed with n-octane, it was dried in an oven at 150° C. for 10 h.

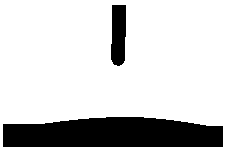

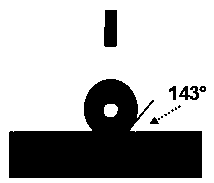

[0029] Such as figure 1 Shown is the surface contact angle test result of the grafted molecular sieve membrane. The contact angle test shows that the surface of the molecular sieve membrane is hydrophilic without grafting treatment. The contact angle test result of the grafted membrane surface...

Embodiment 2

[0031] Step 1, place the molecular sieve membrane in an oven and dry at 100 °C for 2 h.

[0032] Step 2: After mixing n-dodecyltrimethoxysilane and n-octane uniformly at a volume ratio of 1:83, seal both ends of the film and put it inside, and heat at 110 °C for 6 h.

[0033] Step 3: After the grafted membrane was washed with n-octane, it was dried in an oven at 80 °C for 10 h.

Embodiment 3

[0035] Step 1, place the molecular sieve membrane in an oven and dry at 100 °C for 2 h.

[0036] Step 2: After mixing n-dodecyltrimethoxysilane and n-octane uniformly at a volume ratio of 1:50, seal both ends of the film and put it inside, and heat at 110 °C for 6 h.

[0037]Step 3: After the grafted membrane was washed with n-octane, it was dried in an oven at 80 °C for 10 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com