A kind of triptyl vocs cut-off type polymer separation membrane and preparation method thereof

A triptycene and separation membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of limited use, high energy consumption, and cannot be used alone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The specific embodiment of the present invention uses 2,3-diaminotriptycene and sebacoyl chloride as the main monomers for synthesis, triethylamine as the acid-binding agent, and dimethylformamide as the solvent for the synthesis reaction. The specific steps are as follows: Add 1 mol of 2,3-diaminotriptycene, 3.5 mol of triethylamine, and 2.5 mol of sebacoyl chloride into the dimethylformamide solution and stir to dissolve, at a temperature of 2°C (nitrogen protection), After reacting for 3 hours, the homogeneous polycondensation mixed solution of the reaction was coated on the polytetrafluoroethylene base film to prepare a composite film, and the coated composite film was dried in a vacuum oven at 70°C to obtain triptycene-based VOCs interception polymerization material separation membrane.

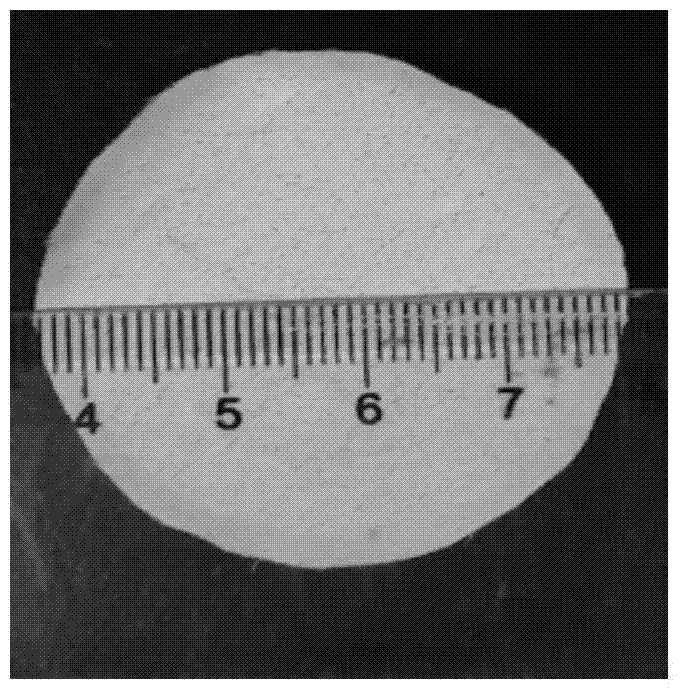

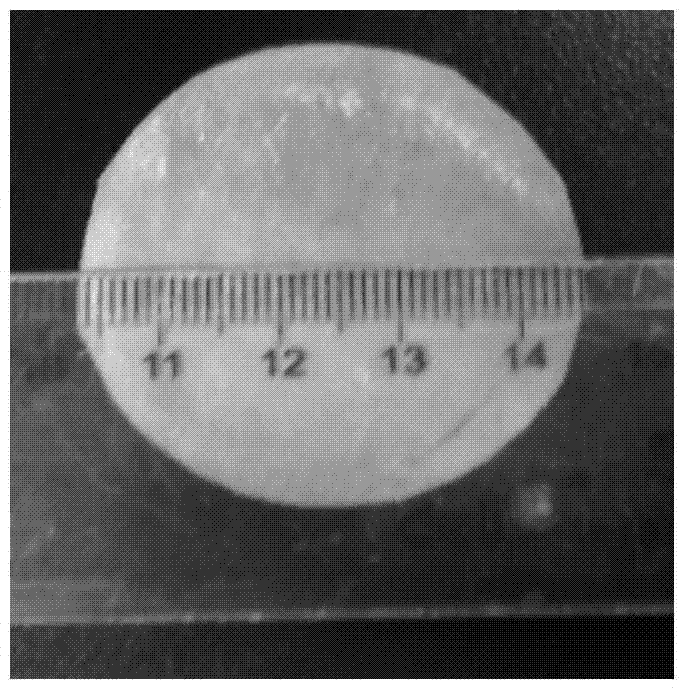

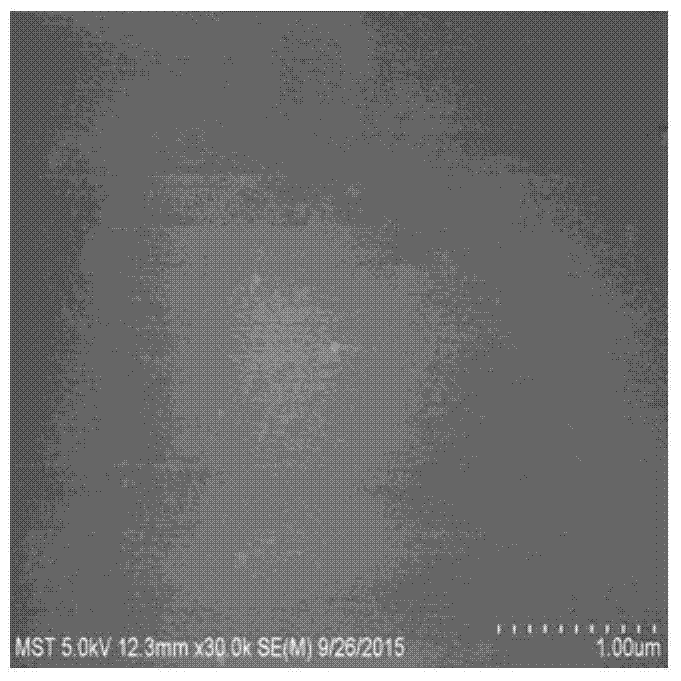

[0059] Digital photo of PTFE backing film figure 1 As shown, the digital photo of triptycene-based VOCs interception polymer separation membrane figure 2 As shown, the SEM imag...

Embodiment 2

[0063] The specific embodiment of the present invention uses 2,6-dihydroxytriptycene and sebacoyl chloride as the main monomers for synthesis, triethylamine as the acid-binding agent, and dichloromethane as the solvent for the synthesis reaction. The specific steps are as follows: 1mol Add 2,3-diaminotriptycene, 4 mol of triethylamine, and 2.5 mol of sebacoyl chloride into the dimethylformamide solution, stir and dissolve, and react for 3.5 hours at a temperature of 2°C (nitrogen protection). , the homogeneous polycondensation mixed solution of the reaction is coated on the polytetrafluoroethylene base film to prepare a composite film, and the coated composite film is dried in a vacuum oven at 70°C to obtain a triptycene-based VOCs interception polymer separation membrane. The average pore diameter of the triptyl VOCs intercepting polymer separation membrane prepared in Example 2 by BET test was 3.4 nm.

[0064] The test conditions are: at 25°C, nitrogen / cyclohexane is used a...

Embodiment 3

[0066] The specific embodiment of the present invention uses 2,6,14-triaminotriptycene and sebacoyl chloride as the main monomers for synthesis, pyridine as the acid-binding agent, and methylpyrrolidone as the solvent for the synthesis reaction. The specific steps are as follows: 1mol Add 2,6,14-triaminotriptycene, 3mol of pyridine, and 2mol of sebacoyl chloride into the methylpyrrolidone solution and stir to dissolve, and react for 3.5h at a temperature of 2°C (nitrogen protection). The homogeneous polycondensation mixed solution was coated on the polytetrafluoroethylene base film to prepare a composite membrane, and the coated composite membrane was dried in a vacuum oven at 70°C to obtain a triptycene-based VOCs interception polymer separation membrane. The average pore diameter of the triptyl VOCs intercepting polymer separation membrane prepared in Example 3 by BET test was 2.8 nm.

[0067] The test conditions are: at 25°C, nitrogen / cyclohexane is used as the separation r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com