A two-dimensional layered zeolite molecular sieve membrane with high separation stability and its preparation method and application

A zeolite molecular sieve membrane and two-dimensional layered technology, which is applied in the field of high separation stability two-dimensional layered zeolite molecular sieve membrane and its preparation, can solve the problems of uncontrollable growth process, poor application and promotion, and complicated preparation conditions. Achieve good separation and selectivity, easy preparation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

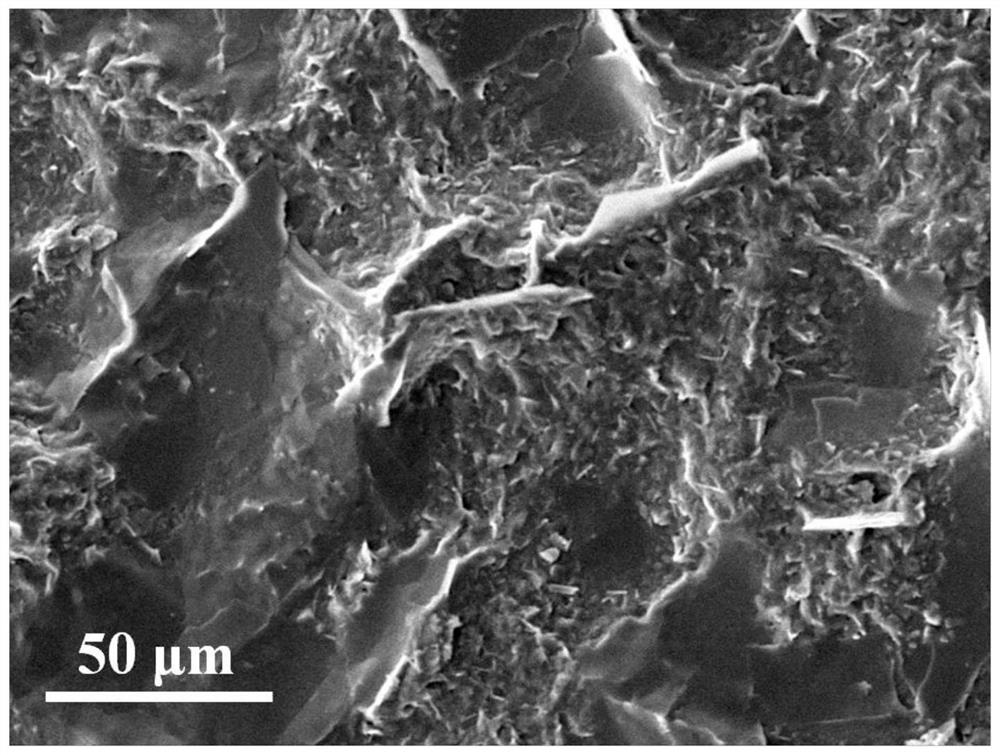

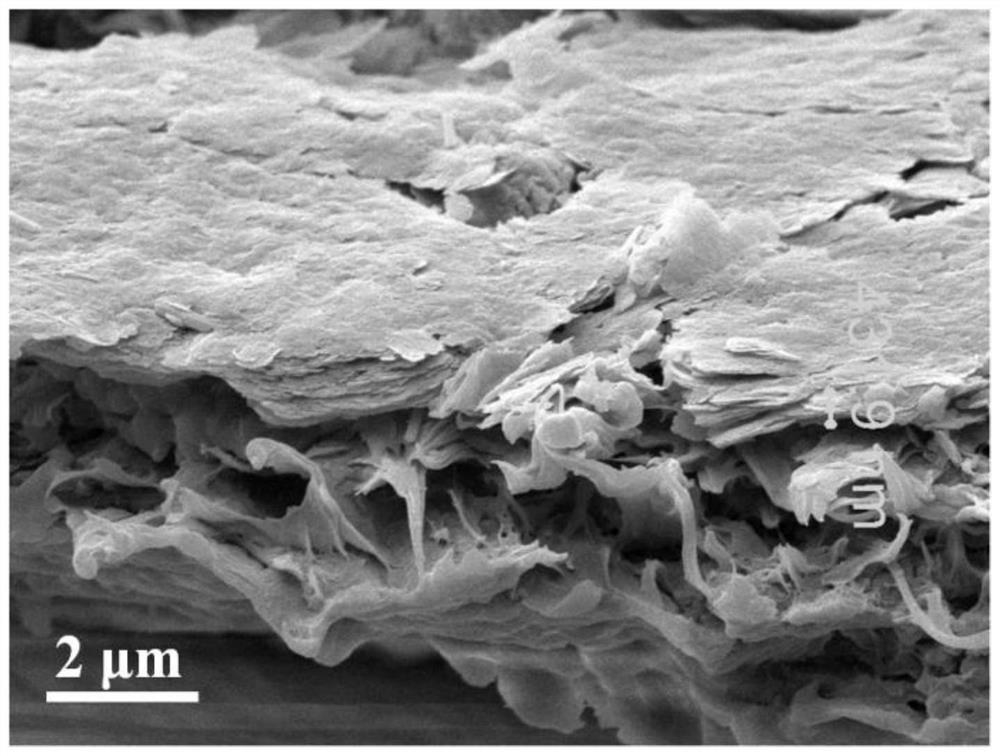

[0041] A preparation method of a two-dimensional layered zeolite molecular sieve membrane with high separation stability, the steps are as follows:

[0042] (1) 10.7ml of cyclohexylimide, 1.4g of sodium hydroxide and 0.75g of sodium aluminate were added to 185ml of distilled water and stirred, and 38.4ml of silica sol (30%) was added to the system to make a mixed solution. After stirring and aging for 5 hours, it was transferred to a stainless steel kettle lined with polytetrafluoroethylene, and crystallized at 150 ° C for 16 days. After the crystallization, washed with water until neutral, and dried to obtain a zeolite precursor (MCM-22 (MCM-22 ( P));

[0043] (2) After stirring the zeolite precursor (MCM-22(P)): CTAB:TPAOH=1:4:1 at room temperature for 16 hours, washing with water and centrifuging to remove the excess swelling agent to obtain the swollen MWW zeolite MCM-22 ( S), take 1g of MCM-22(S) and 10ml of hydroxyl-terminated polybutadiene to mix ultrasonically for 24 ...

Embodiment 2

[0046] A preparation method of a two-dimensional layered zeolite molecular sieve membrane with high separation stability, the steps are as follows:

[0047] (1) 12.49ml of cyclohexylimide, 1.8g of sodium hydroxide and 0.36g of sodium aluminate were added to 133ml of distilled water and stirred, and 36.58ml of silica sol (30%) was added to the system to make a mixed solution. After stirring and aging for 24 hours, it was transferred to a stainless steel kettle lined with polytetrafluoroethylene, crystallized at 160 ° C for 21 days, washed with water to neutrality after crystallization, and dried to obtain a zeolite precursor (MCM-22 (MCM-22 ( P));

[0048] (2) After stirring the zeolite precursor (MCM-22(P)): CTAB:TPAOH=1:5.6:2.4 at room temperature for 16 hours, washing with water and centrifuging to remove the excess swelling agent to obtain the swollen MWW zeolite MCM-22 ( S), take 1 g of MCM-22 (S) and 10 ml of hydroxyl-terminated polybutadiene in chaotic flow and stir for...

Embodiment 3

[0051] A preparation method of a two-dimensional layered zeolite molecular sieve membrane with high separation stability, the steps are as follows:

[0052] (1) 0.17g Al 2 (SO 4 ) 3 ·18H 2 O and 0.4ml H 2 SO 4 Add 300ml of distilled water, dissolve and add 1.86g[C 22 H 45 -N + (CH 3 ) 2 -C 6 H 12 -N + (CH 3 ) 2 -C 6 H 13 ]Br 2 and 12.7ml of ethanol, then 0.5g of NaOH was added, and 15.4ml of ethyl orthosilicate was added dropwise to the above system under vigorous stirring to make a mixed solution. After stirring and aging for 24 hours, the mixed solution was transferred to polytetrafluoroethylene In a stainless steel kettle lined with vinyl fluoride, crystallize at 160 °C for 7 days. After the crystallization, wash with water until neutral, and dry to obtain zeolite precursor (MFI);

[0053] (2) 1 g of zeolite precursor (MFI) and 10 ml of carboxyl-terminated polybutadiene were stirred in a chaotic flow for 1 hour to prepare a 10% two-dimensional zeolite susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com