A method of oilfield water injection that can achieve balanced displacement of remaining oil

A technology for oil field water injection and remaining oil, which is applied in earth-moving drilling, fluid production, wellbore/well components, etc., can solve problems such as poor oil displacement effect and low oil recovery rate, and achieve balanced displacement and enhanced recovery. rate, the effect of improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

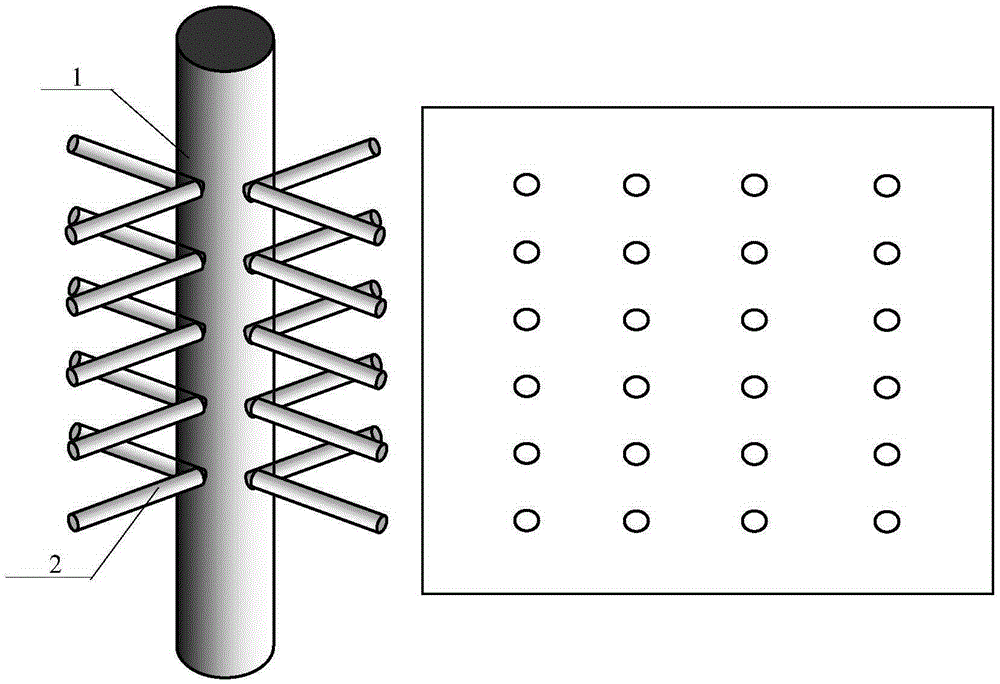

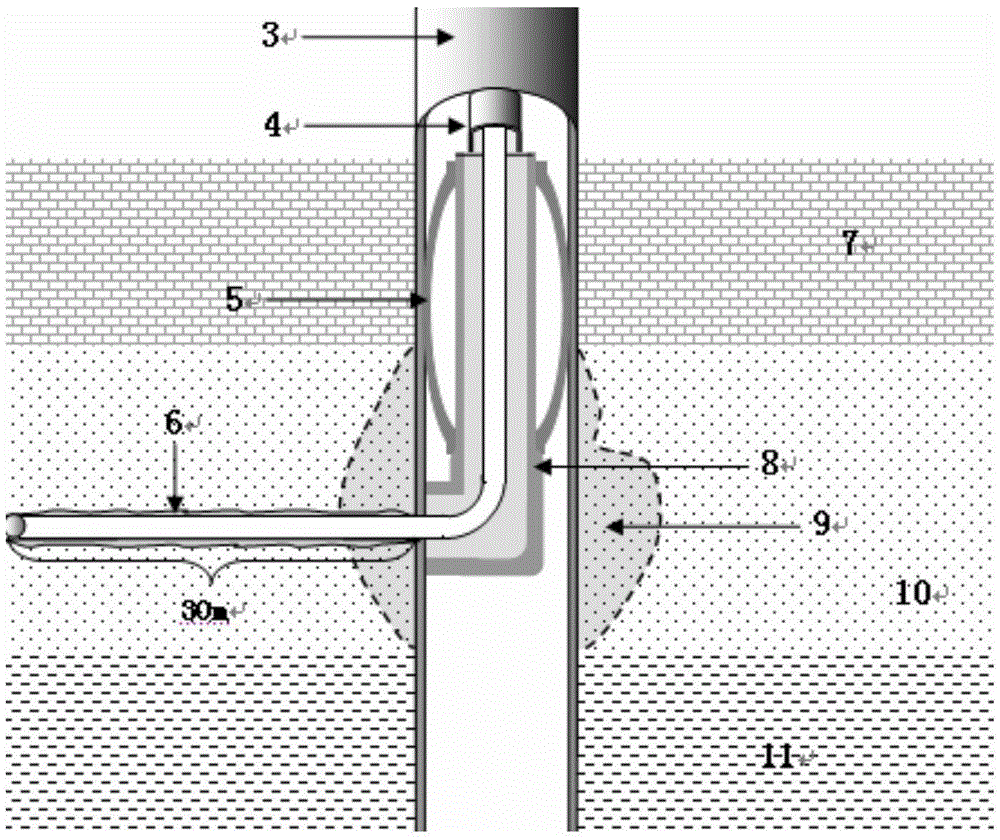

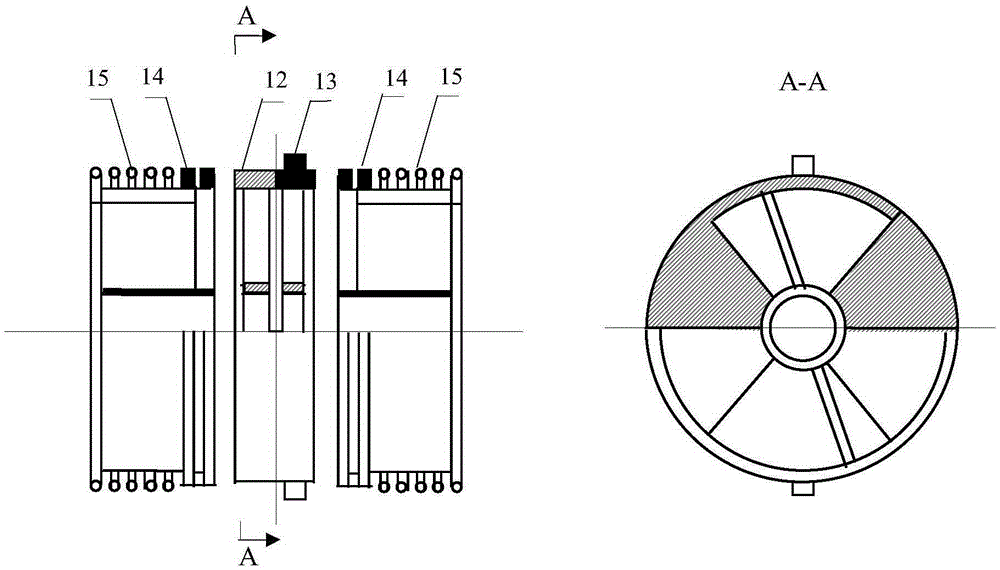

[0028] The present invention will be further explained below in conjunction with the drawings:

[0029] At present, in the field of petroleum exploration and development, there is no method that can adapt to the heterogeneity of the reservoir to adjust the water injection rate. At present, the normal perforation completion method in water injection wellbore is to perform spiral drilling on the wellbore, that is, first perform perforation at a suitable position on the wellbore, and then perform a certain distance above that position. Continue perforating with the phase angle, and then repeat the above construction steps with this perforation point as the new base point, and continue until the required perforation is completed. The spiral well formed in this way has a small number of holes, and the scope of water injection is limited. The plane can only target the remaining oil in one direction, and cannot take into account other directions. Moreover, the hole depth formed by perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com