A test method using an oil-water distribution tester

A testing method and testing instrument technology, which is applied in construction and other fields, can solve problems such as the difficulty in determining the water outlet level of horizontal wells in oil fields, and achieve the effects of improving development effects, increasing emission energy, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

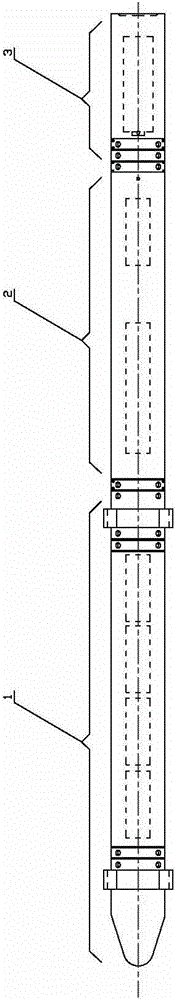

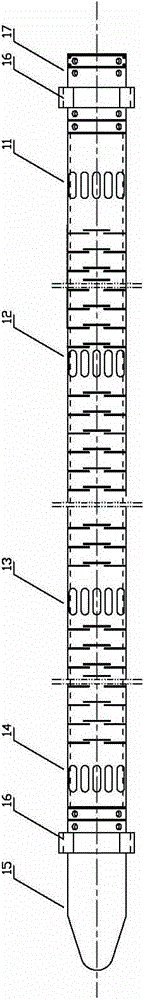

[0052] Before going into the well for testing, set the sampling mode of the host part of the instrument through the host computer software. Then connect the acoustic wave system 1 downwards and the battery 3 upwards respectively. After the overall connection of the instrument is completed, it is connected to the front end of the working string for lifting and lowering, and the tail cap end of the acoustic wave system is directed in line with the drilling direction. The instrument is tested and stored throughout the lifting process. The set sampling method is reasonably set according to well conditions and production stages. After the test is completed, take out the instrument, remove the host 2, communicate with the host computer online, and play back the data. The comprehensive interpretation software of the test can draw various logging curves, that is, the sound amplitude, variable density, oil-water distribution wave train curve, water Oil-water distribution curve of fla...

Embodiment 2

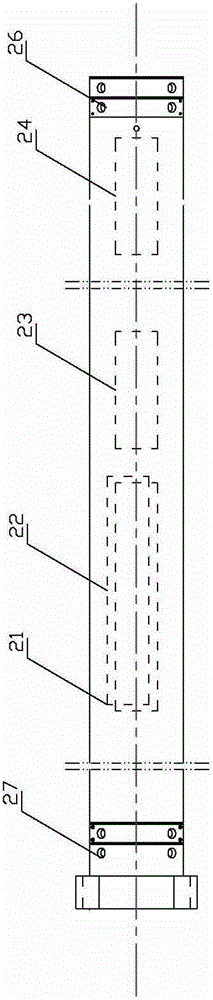

[0054] Such as Figure 4 As shown, this method can also be used in combination with temperature and pressure testers, and the effect of periodic injection and production of thermal recovery horizontal wells can be analyzed through the joint application of acoustic wave curves, water finding method with slight temperature difference, and temperature and pressure profile curves in the horizontal section.

[0055] The assembly steps of the oil-water distribution tester of the present invention are the same as those in Embodiment 1. Before being connected to the working pipe string, the end of the battery cylinder away from the main engine is passed through the screw thread and the temperature sensor 41, the pressure sensor 42, the micro-temperature difference control board 43 and the magnetic positioner. 24 components are connected and then lifted and unloaded. The instrument is tested and stored throughout the lifting process. The set sampling method is reasonably set according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com