Sand filling tube combination device for simulating fractured reservoir

A technology for simulating fractures and combined devices, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems that cannot simulate the water injection development of fractured reservoirs, and achieve the effect of delaying the water flooding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

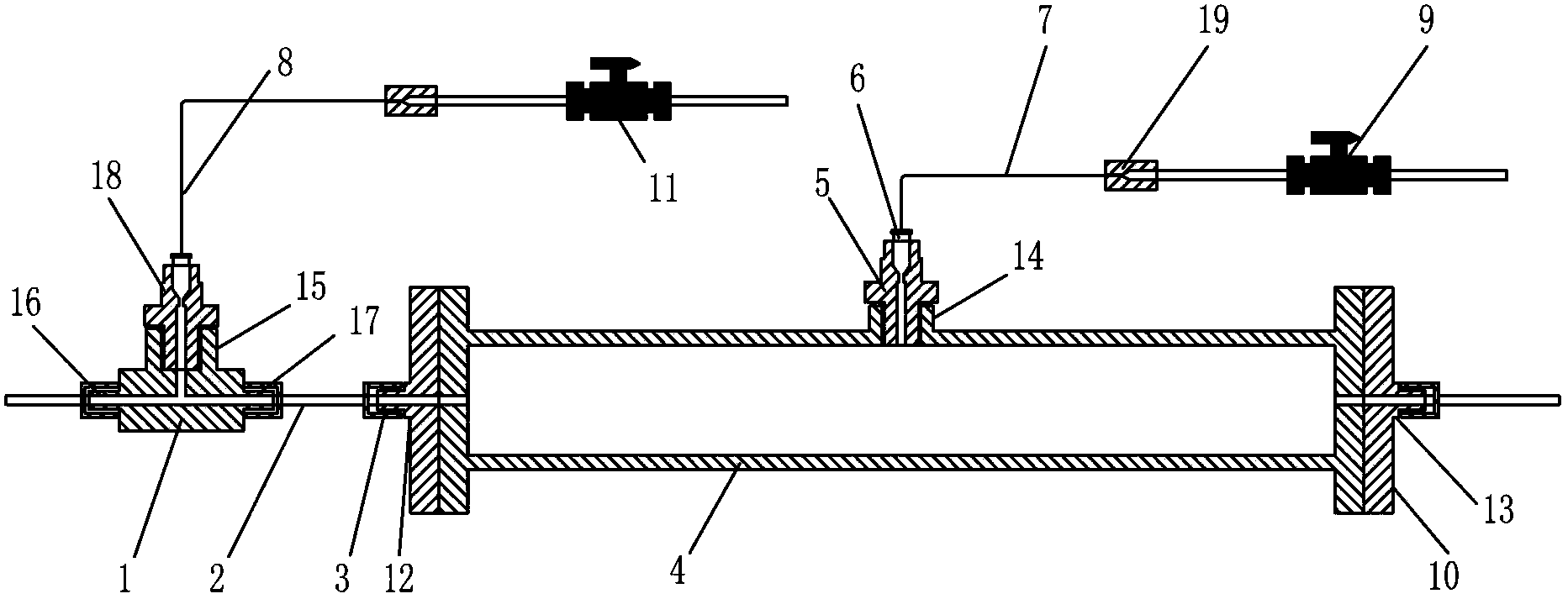

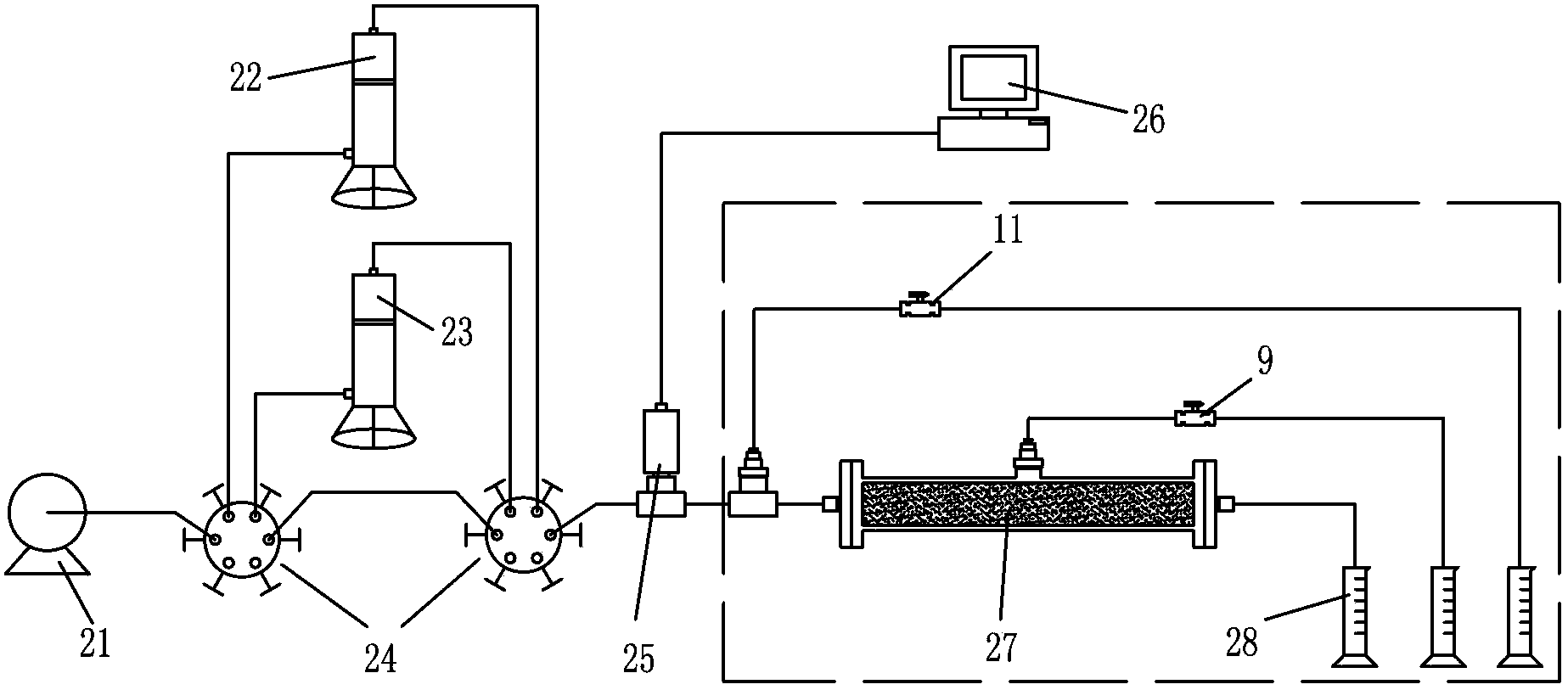

[0020] The sand filling pipe assembly device of the present invention includes a cylindrical shell 4, capillary tubes 7, 8, which are used to provide seepage passages and cracks; wherein the cylindrical shell 4 and the capillary tube 7 are sealed and connected by a variable diameter joint C5; the cylindrical shell 4 The two ends are sealed and connected with the flange 10 through connecting screws; the flange is provided with a sealed pipeline joint 3; the two ends of the tee base are provided with a sealed pipeline joint 3; the tee base is connected with the cylindrical cylinder 4 through a stainless steel tube 2 , used to closely connect with the indoor displacement pipeline to provide a liquid flow channel; the end of the valve 9, the valve 11, and the end of the flange 10 are closely connected with the indoor displacement pipeline to provide a liquid flow channel.

[0021] When using the sand packing pipe combination device of the present invention, the valve 9 is opened an...

Embodiment 2

[0026] The connection method is as in embodiment 1

[0027] When using the sand packing pipe combination device of the present invention, the valve 9 is opened and the valve 11 is closed, so as to simulate the formation situation in which the starting position of the fracture is between the water injection well and the water outlet well in the low permeability oil field, and the end of the fracture is connected with the water outlet wellhead.

[0028] The inner diameter of the sand filling pipe is 38mm, the outer diameter is 50mm, and the length is 300mm; the diameter of the flange 10 is 78mm; the reducing joint C 5 is welded by a nut with a diameter of 12mm and a joint with an inner diameter of 1 / 16 inch. A hole with an inner diameter of 3 mm is opened in the middle of the nut; a capillary with an inner diameter of 200 μm, an outer diameter of 1 / 16 inch, and a length of 100 mm is used as a crack to simulate a natural fracture in the formation.

[0029] Keeping the water injec...

Embodiment 3

[0031] The connection mode of this combination device is as embodiment 1

[0032] When using the sand-packing pipe combination device of the present invention, the valve 11 is opened and the valve 9 is closed, so as to simulate the stratum situation in which fractures run through the water injection well and the water outlet well.

[0033] The inner diameter of the sand filling pipe is 20mm, the outer diameter is 30mm, and the length is 200mm; the diameter of the flange 10 is 40mm; the reducing joint D 18 is welded by a nut with a diameter of 12mm and a joint with an inner diameter of 1mm. A hole with an inner diameter of 3 mm is opened in the middle; capillary tubes with an inner diameter of 100 μm, an outer diameter of 1 mm, and a length of 100 mm are used for the fractures to simulate natural fractures in the formation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com