Calibration system and control method for speed given signal of diesel locomotive diesel engine

A given signal, diesel locomotive technology, applied in the direction of engine control, fuel injection control, electrical control, etc., can solve the problems of being easily affected by device aging, large cumulative error, and low control accuracy, so as to meet the needs of locomotive operators, Avoid the effect of speed overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

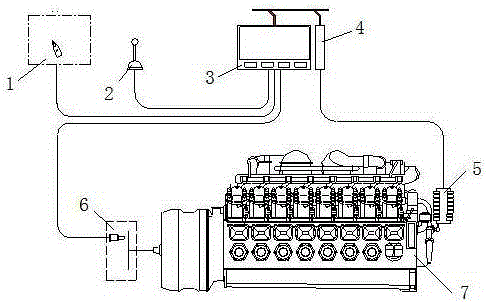

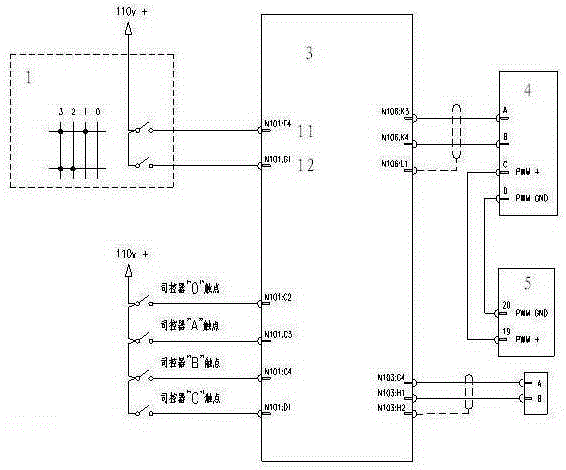

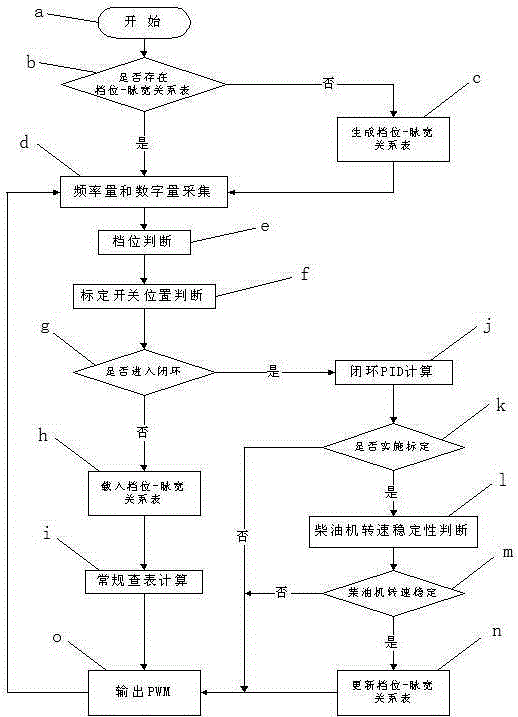

[0032] like figure 1 It is a schematic diagram of the structure of the present invention, a diesel locomotive diesel engine speed given signal calibration system, which consists of a diesel engine speed given signal calibration switch 1, a driver gear handle 2, a vehicle-mounted microcomputer 3, a diesel engine speed control board 4, and an EFI controller 5. The diesel engine speed detection module 6 is composed of a vehicle-mounted microcomputer 3 as the control core. The wires are connected with the driver gear handle 2 and the diesel engine speed detection module 6 respectively, and the vehicle-mounted microcomputer 3 is connected with a diesel engine speed given signal calibration switch 1 through hard wires. The "calibration switch for given signal of diesel engine speed" is actually a 10,000-turn switch, which has two sets of contacts, and can input and output 4 kinds of switching states as shown in Table 1 to the microcomputer. The on-board microcomputer judges the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com