Low-voltage and high-current rotating test rig

A rotating test, high current technology, applied in circuit breaker testing and other directions, can solve the problems of inconvenient handling, high cost of double-layer turntable, difficult maintenance of power supply equipment, etc., to prevent inadvertent operation, shorten time spent, tripping The effect of time convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

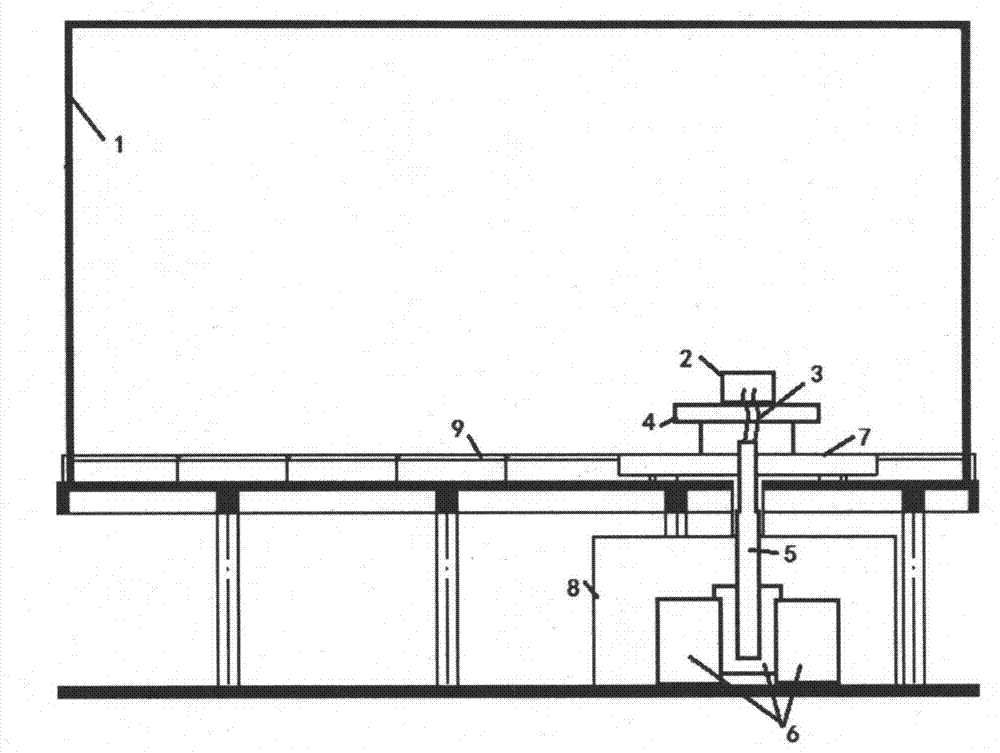

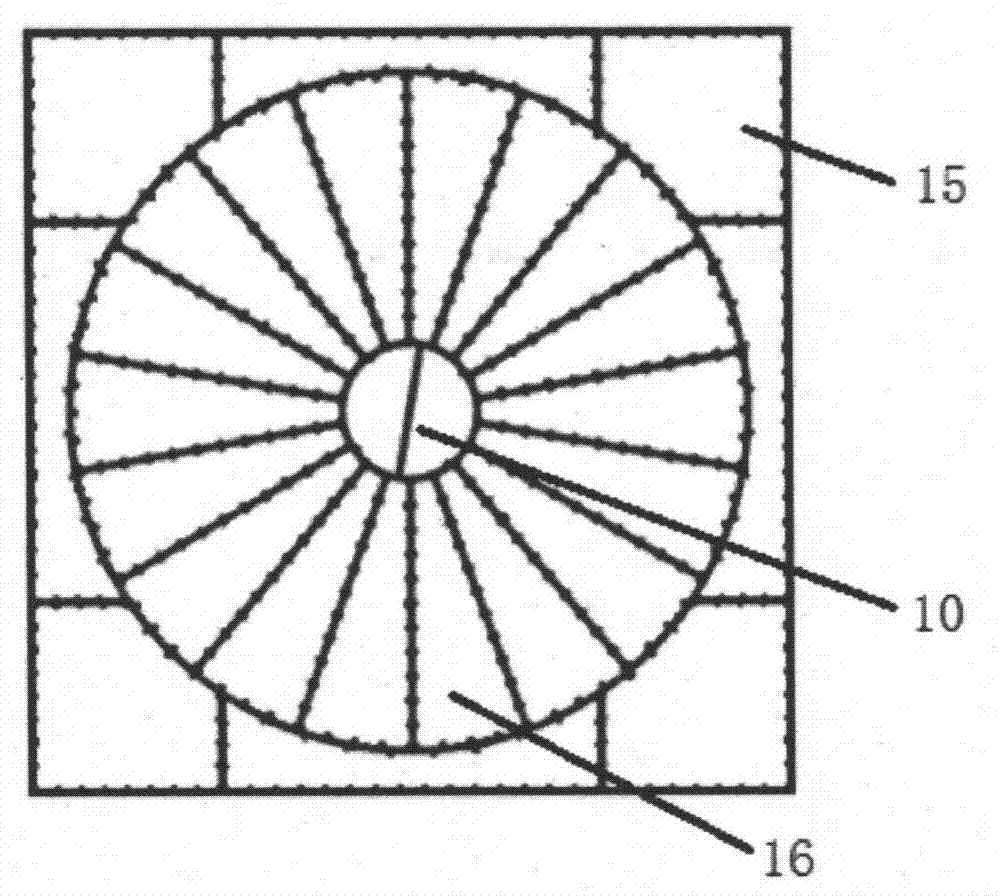

[0030] Such as figure 2 Shown is a schematic diagram of the structure of a low-voltage, high-current rotary test device. The low-voltage, high-current rotary test device includes an anechoic chamber 1, and the anechoic chamber 1 is provided with a grounding plate 9 and a turntable 7 embedded in the grounding plate 9. The turntable 7 is located at On one side of the anechoic chamber 1, an insulation test table 4 is provided on the turntable 7, and the test object 2 is set on the insulation test table 4. The center of the turntable 7 is provided with a center hole 10 of the turntable, and a copper bar 5 is provided in the center hole 10 of the turntable. One end of the copper bar 5 is connected to the power supply end of the low-voltage high-current power supply device 6 , and the other end is connected to the tested product 2 through the flexible connection wire 3 . The shield room 8 is located underground. The flexible connecting wire 3 is a copper braid.

[0031] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com