Polarized structure and liquid crystal display

A liquid crystal display and polarizing technology, which is applied in optics, instruments, diffraction gratings, etc., can solve the problems of polarizer deformation, light leakage, and affecting the picture quality of liquid crystal displays, and achieve the effects of shortening time, saving polarizing materials, and increasing picture quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

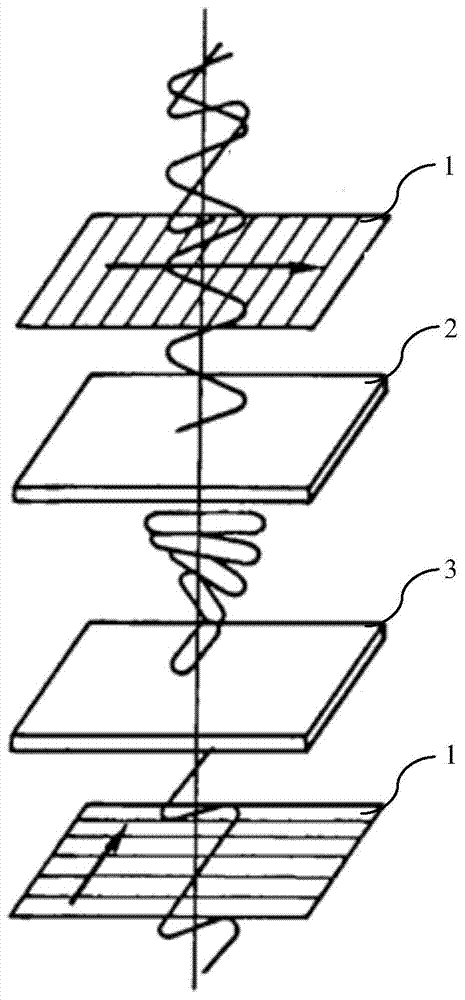

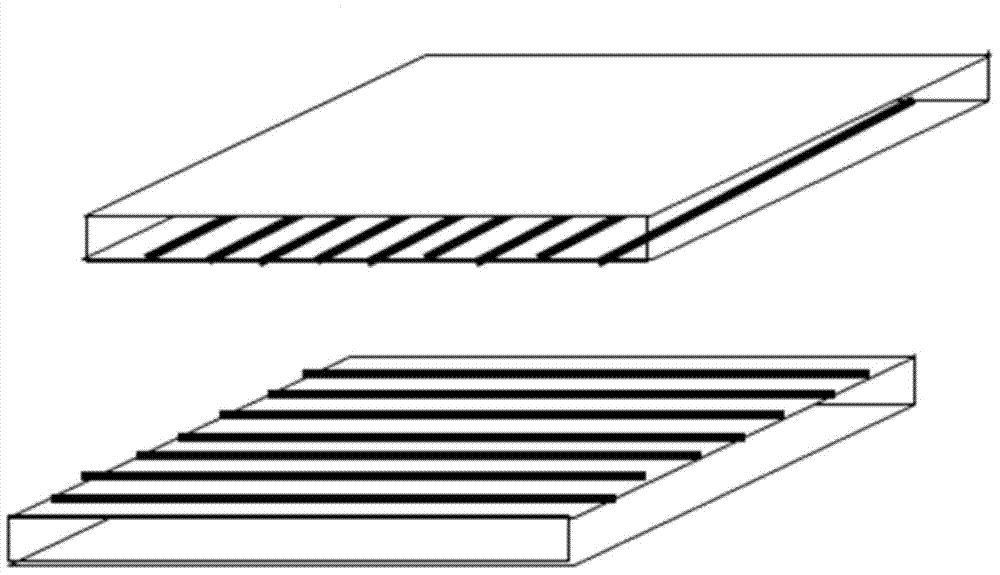

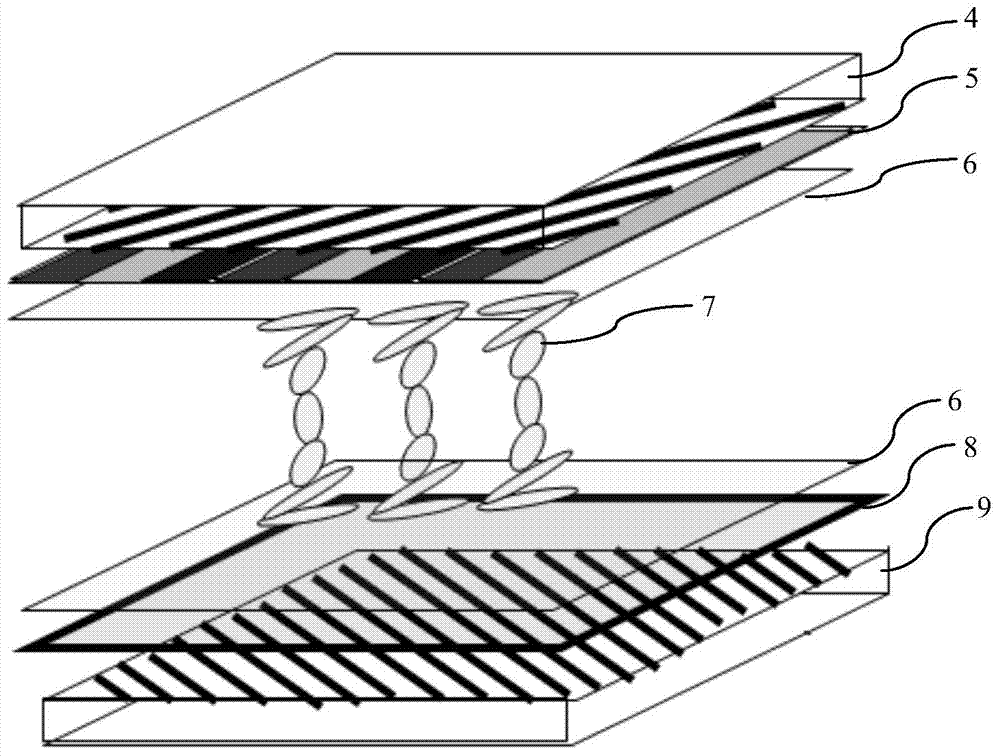

[0020] Such as figure 2 The polarizing structure shown includes two transparent glass plates parallel to each other, and a metal grating layer is respectively arranged on the inner surfaces of the two transparent glass plates, and the metal grating layer includes a plurality of metal lines parallel to each other, wherein the two transparent glass plates The axial angles of the metal wires on the plates differ by 90°, wherein the axial angle of the upper transparent glass plate is 90°, and the axial angle of the lower transparent glass plate is 0°. The metal wire can be chrome wire, silver wire or aluminum wire. When the electromagnetic wave passes through the polarizing structure, it is polarized, that is, when the electromagnetic wave passes through the metal grating layer, the light in one directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com