Manual interlocking device of three-station mechanism

An interlocking device, three-station technology, applied in the direction of air switch parts, etc., can solve the problems of inability to feedback the state information of the mechanism to other components in the system, large sliding resistance, and laborious sliding, etc., to eliminate existing defects. , easy to operate, improve reliability and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

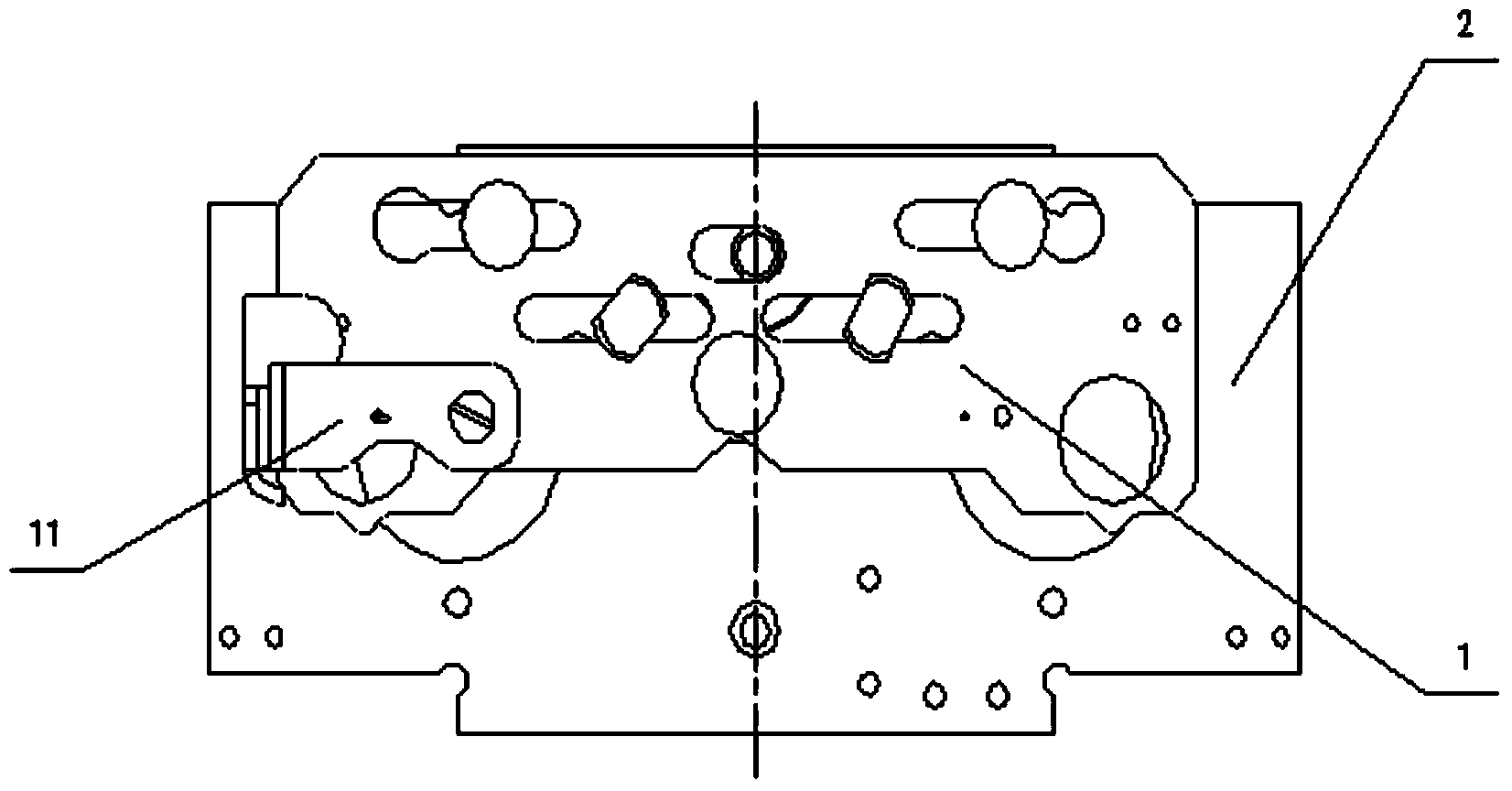

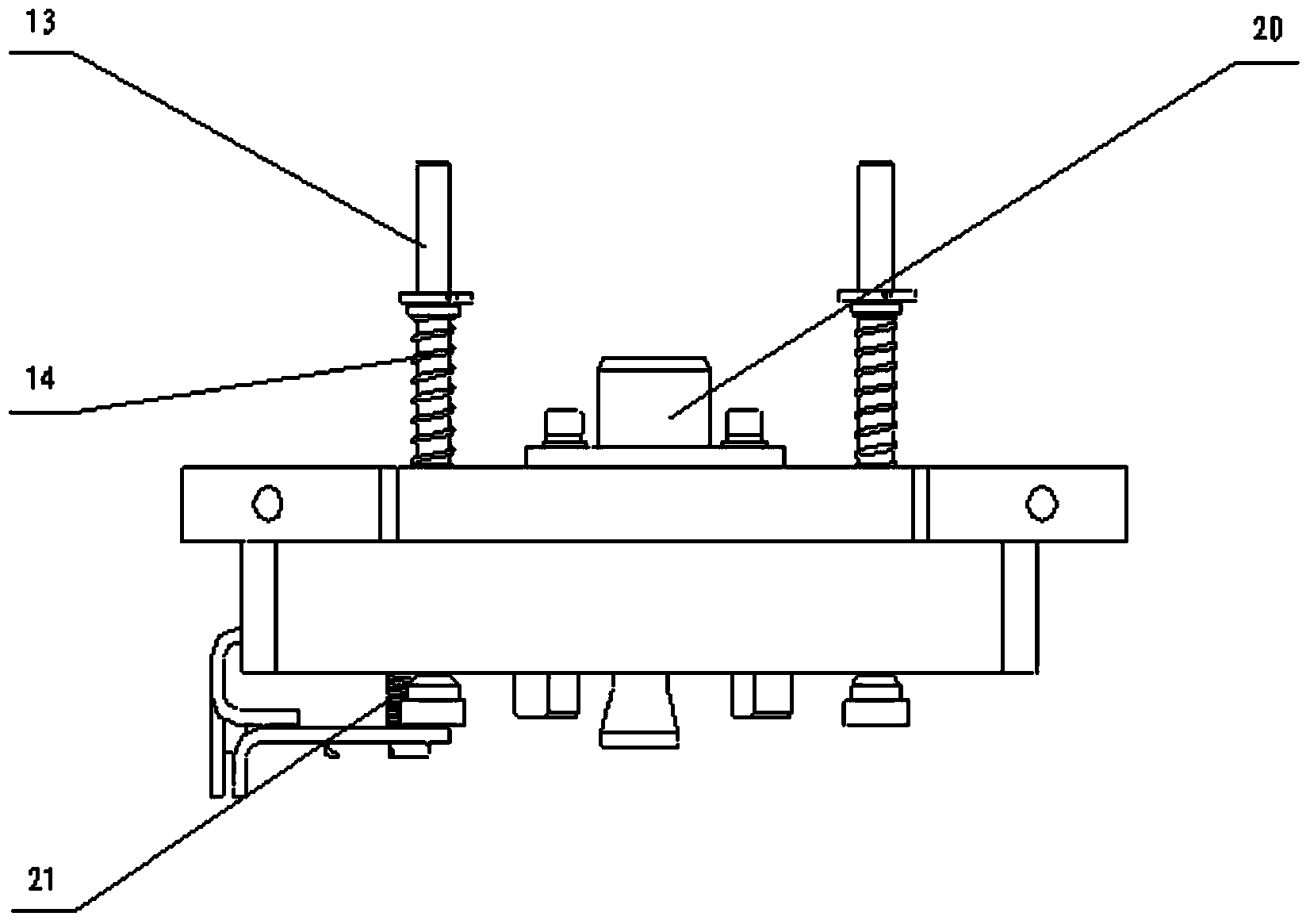

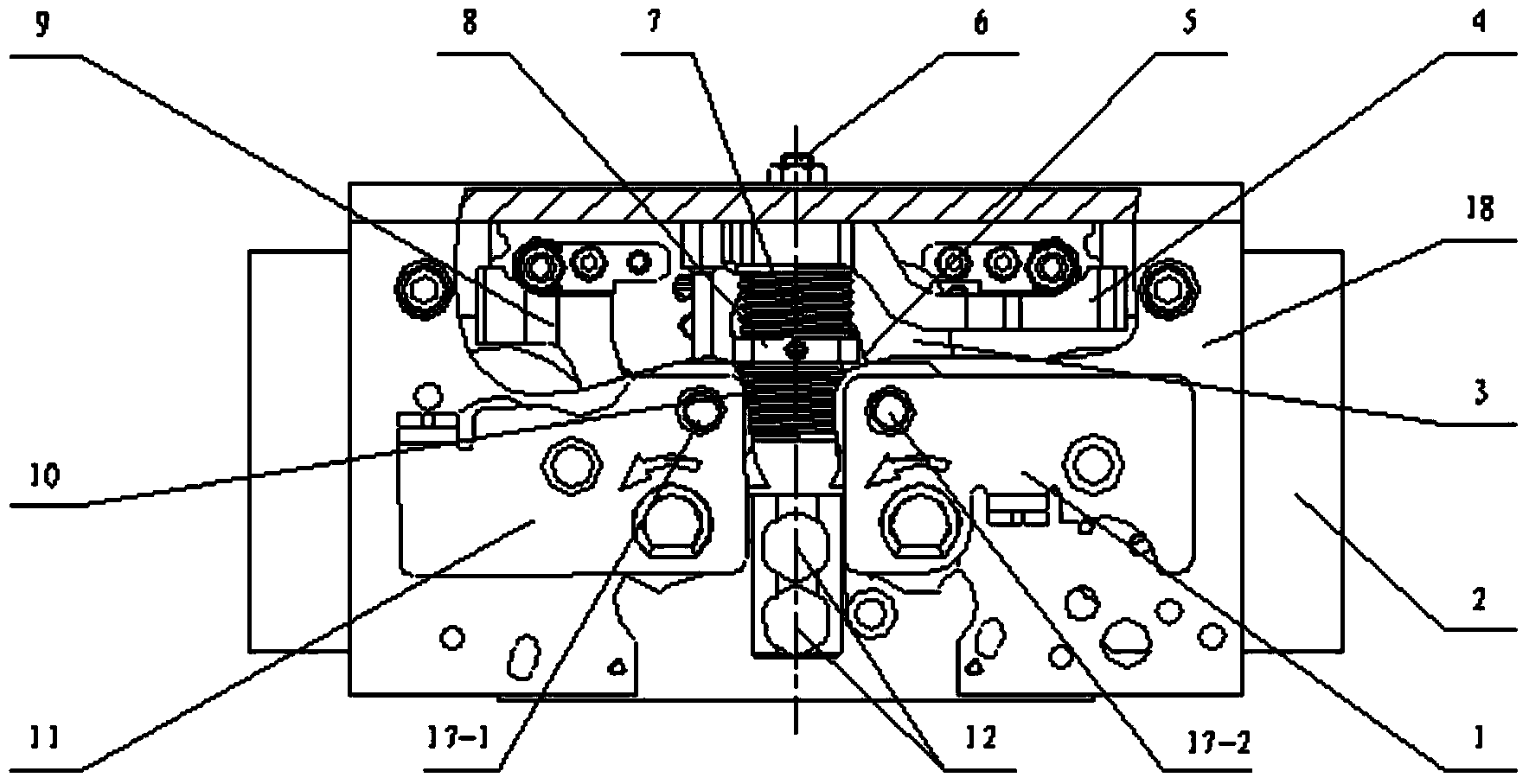

[0031] As shown in Figure 2(a) and 2(b), the manual interlock of the three-position mechanism and its interlock device include the side plate 2 set on the mechanism, the ES drive pin 13-1 inserted into the side plate 2 and the DS drive Pin 13-2, and the support plate 18 that is fixed on the front end of side plate 2 in parallel; Side plate 2 is respectively provided with DS baffle plate 1 and ES baffle plate 11, and the baffle plate shaft of DS baffle plate 1 and ES baffle plate 11 is provided with There are DS cam 3 and ES cam 5, and the support plate 18 of the mechanical interlock device is respectively provided with ES interlock pin 17-1 and DS interlock pin 17-2, ES interlock pin 17-1 and DS interlock pin 17- 2 Corresponding to the pin holes on DS baffle 1 and ES baffle 11 respectively, the interlock pin is set as the passive part of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com