Article separation and conveyance device

A technology for conveying devices and articles, applied in the direction of conveyors, conveyor objects, vibrating conveyors, etc., to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

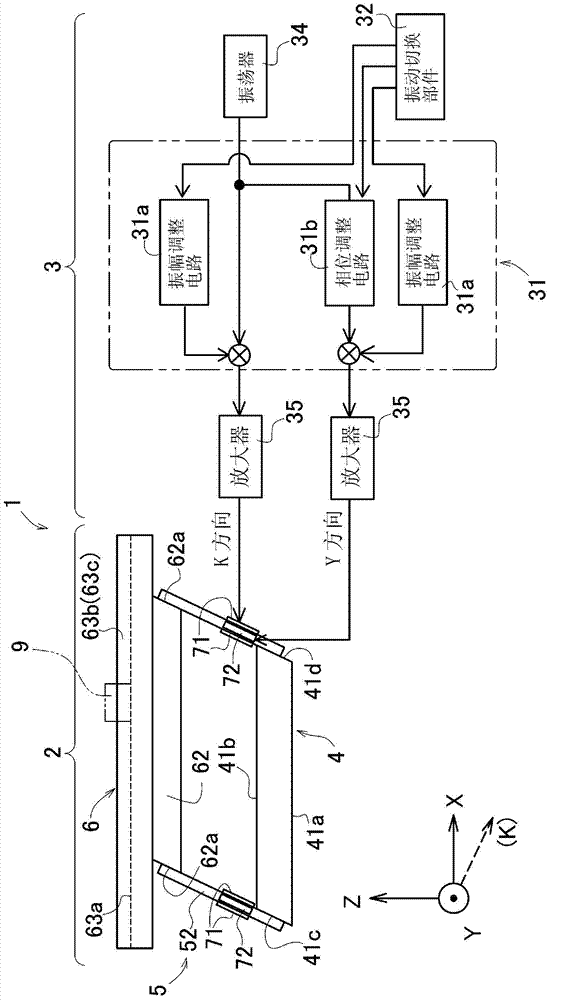

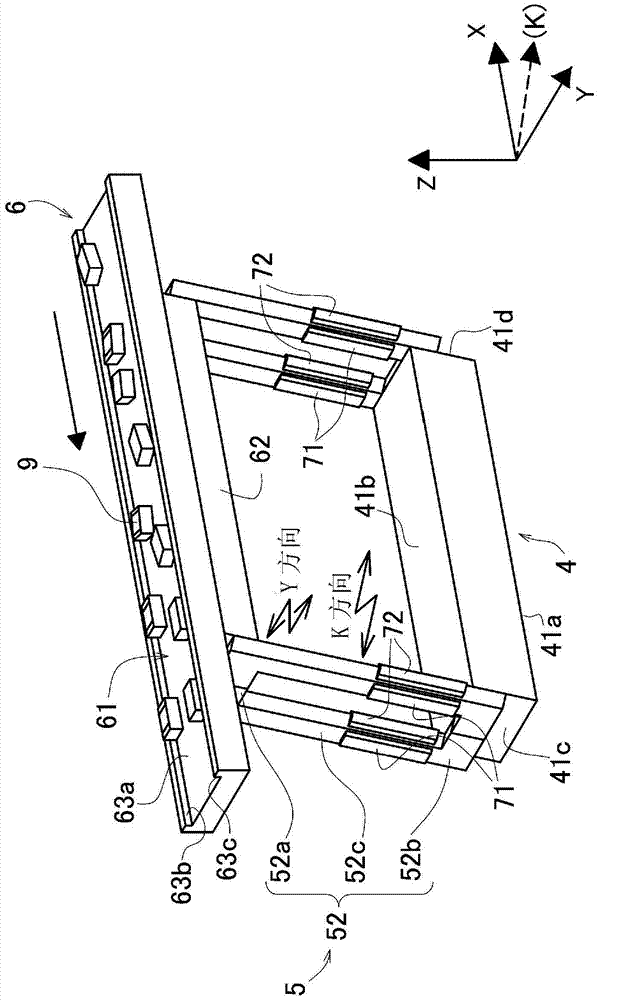

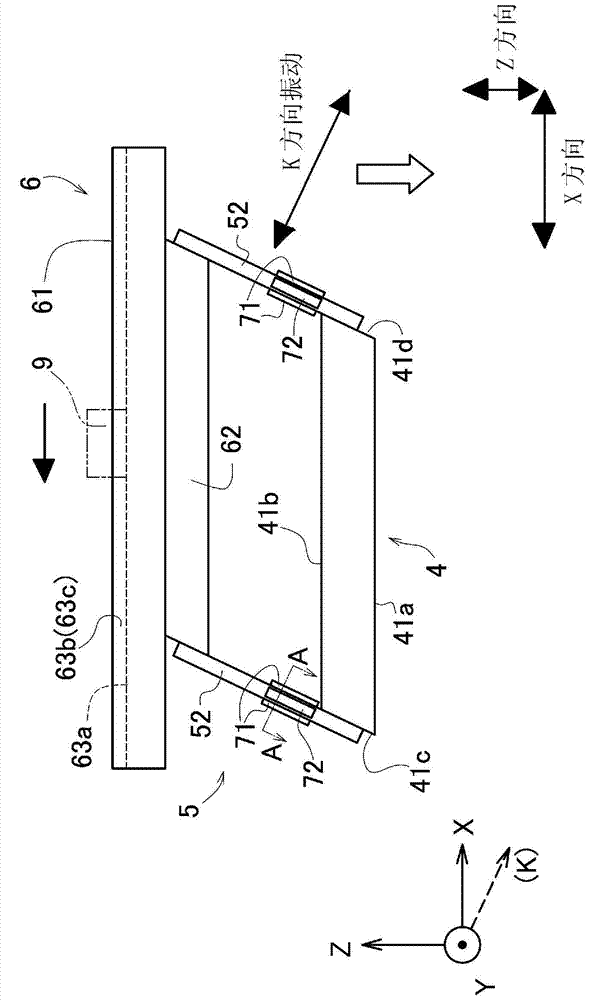

[0053] Such as figure 1 As shown, the article sorting and conveying device 1 of the first embodiment is generally composed of a mechanism unit 2 and a control system unit 3 . The control system unit 3 is configured to apply periodic vibration forces in the K and Y directions to the mechanical unit 2 by controlling the piezoelectric elements 71 and 72 incorporated in the mechanical unit 2 as described later to generate vibration.

[0054] Here, in the present embodiment, the K direction refers to a direction perpendicular to the attachment surface of the piezoelectric element 71 to the elastic supporting member 52 , and the Y direction refers to a direction perpendicular to the drawing. In addition, the X and Z directions described later are also defined as indicated by the coordinate axes shown on the lower left in the figure. Therefore, the K direction can be said to be a direction parallel to the XZ plane, which is a plane having X-direction and Z-direction components. H...

no. 2 Embodiment approach

[0097] Such as Figure 13 As shown, the article sorting and conveying device 201 of the second embodiment is generally composed of a mechanism unit 202 and a control system unit 203 . The control system unit 203 is configured to apply vibrations in the K and Y directions to the mechanism unit 202 by controlling the piezoelectric elements 281 to 282 as vibrating members incorporated in the mechanism unit 202 as will be described later. Periodic initiating force and vibration.

[0098] Here, also in this embodiment, the Y direction refers to the horizontal direction perpendicular to the paper surface in the drawing, and the K direction refers to the rod-shaped spring member 272 provided obliquely from the vertical direction in the same manner as in the above-mentioned first embodiment. Orthogonal and perpendicular to the above-mentioned Y direction. In addition, the X direction mentioned later means the horizontal direction orthogonal to the said Y direction, and the Z directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com