Heating of an exhaust-gas after-treatment system by dragging of an internal combustion engine with the aid of an electric motor

A waste gas post-treatment and waste gas heating technology, which is applied in exhaust gas treatment, mechanical equipment, and electric control of exhaust gas treatment devices, can solve problems such as flameout, uneven operation, and inability to compensate losses, so as to save CO2 and improve exhaust gas temperature, enhancing the effect of heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

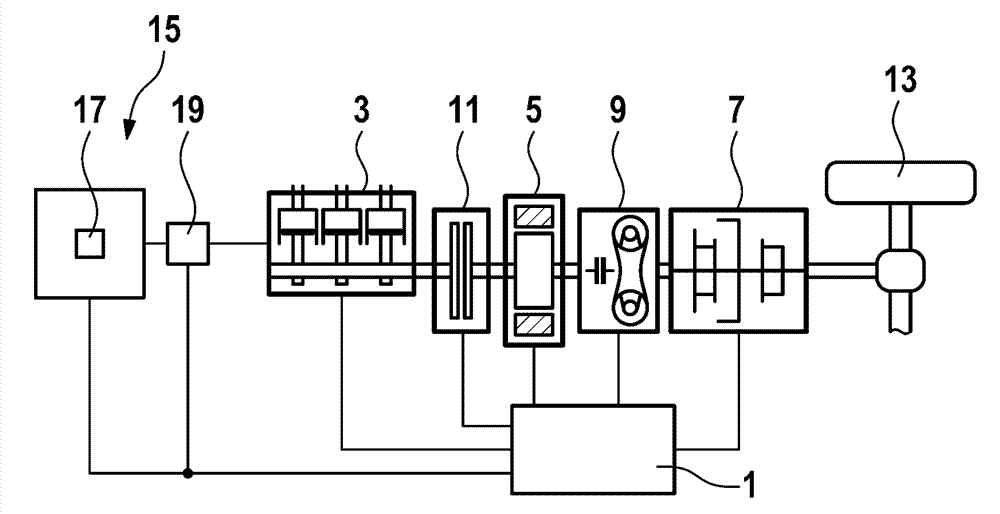

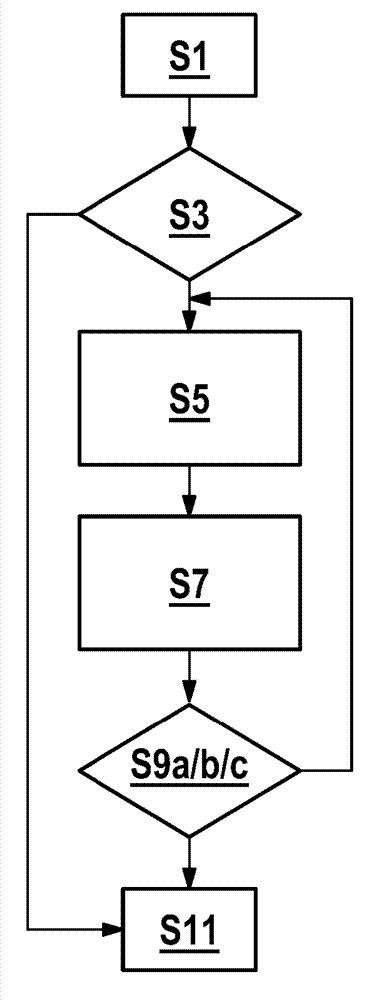

[0031] exist figure 1 A schematic diagram of a method according to an embodiment of the invention is shown in . In step S1 internal combustion engine 3 is started. In step S3 , the need to heat the exhaust gas aftertreatment device is detected. A possible reason for the need for heating can be, for example, a cold start of the internal combustion engine 3 . In order to detect the need to heat the exhaust gas aftertreatment device 15 , the current temperature of the exhaust gas aftertreatment device 15 can be measured and compared with a temperature target value similarly to step S9 a. Alternatively, a cold start can be detected directly on the internal combustion engine. If the system determines that exhaust-gas aftertreatment device 15 must be heated, electric motor 5 is actuated in a step S5 in such a way that it pulls or operates internal combustion engine 3 . In this case, electric motor 5 is adjusted in such a way that it operates internal combustion engine 3 with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com