Rectangle cover full-automatic press-fit hydraulic machine

A rectangular cover and hydraulic press technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low safety guarantee factor, unstable press fit quality, high labor intensity of personnel, etc., and achieve low labor intensity, structural Simple, productive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings.

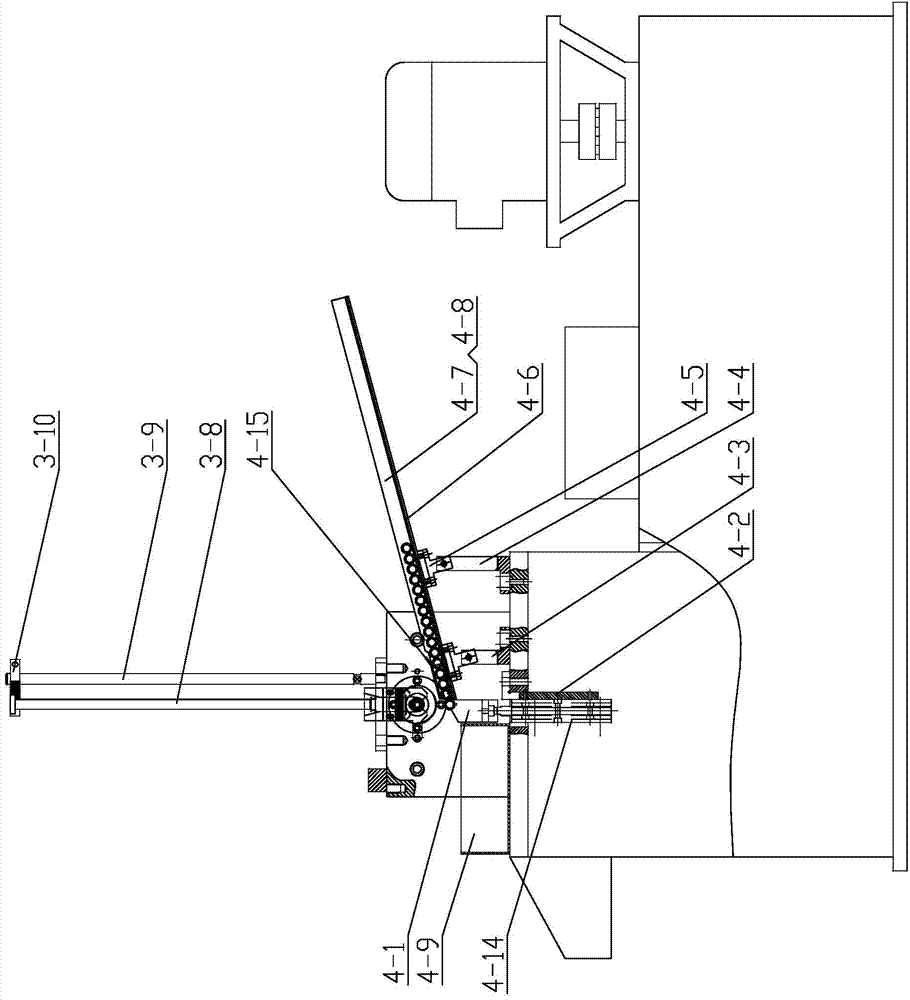

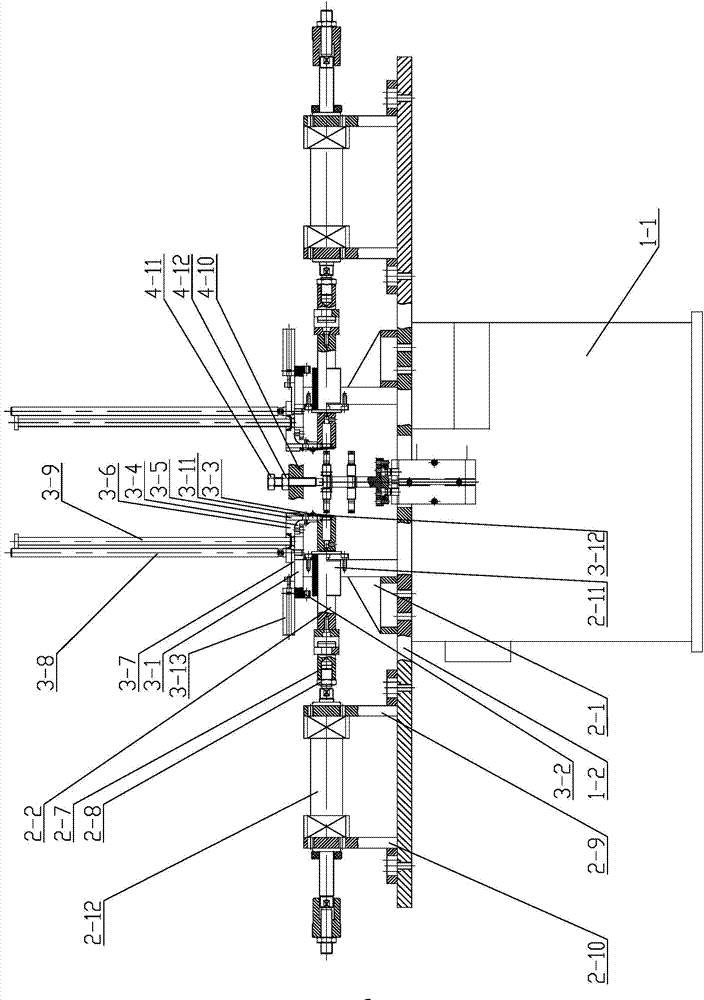

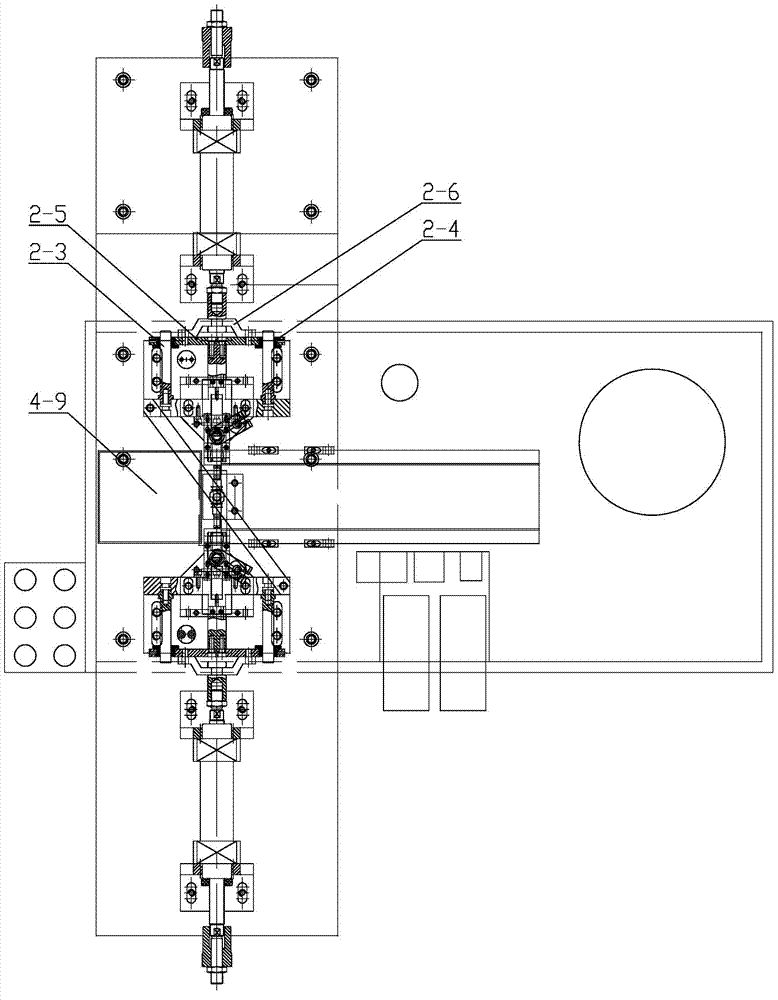

[0016] Such as Figure 1 ~ Figure 3 As shown: the rectangular cover automatic press-fitting hydraulic machine includes a bed 1-1, a bottom plate 1-2, a base 2-1, a rectangular cover die 2-2, a guide rod 2-3, a sliding sleeve 2-4, Connecting plate 2-5, V-shaped connecting plate 2-6, connecting shaft 2-7, lock nut 2-8, oil cylinder front positioning plate 2-9, oil cylinder rear positioning plate 2-10, linear bearing 2-11, oil cylinder 2-12. Adjustable bottom plate 3-1, limit block 3-2, pin shaft 3-3, lane change block 3-4, rectangular cover material channel 3-5, rectangular cover positioning plate 3-6, rectangular cover Push plate 3-7, optical axis 3-8, rectangular cover string rod 3-9, string rod adjustment block 3-10, rectangular cover fixed baffle 3-11, rectangular cover movable baffle 3-12, rectangular cover cylinder 3 -13, workpiece positioning block 4-1, cylinder fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com