Solid wood panel and production method thereof

A production method and technology for solid wood panels, which are used in the joining of wooden veneers, wood processing appliances, manufacturing tools, etc., can solve the problems of poor impact resistance, easy bending deformation, easy cracking, etc. Service life, guarantee the effect of expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

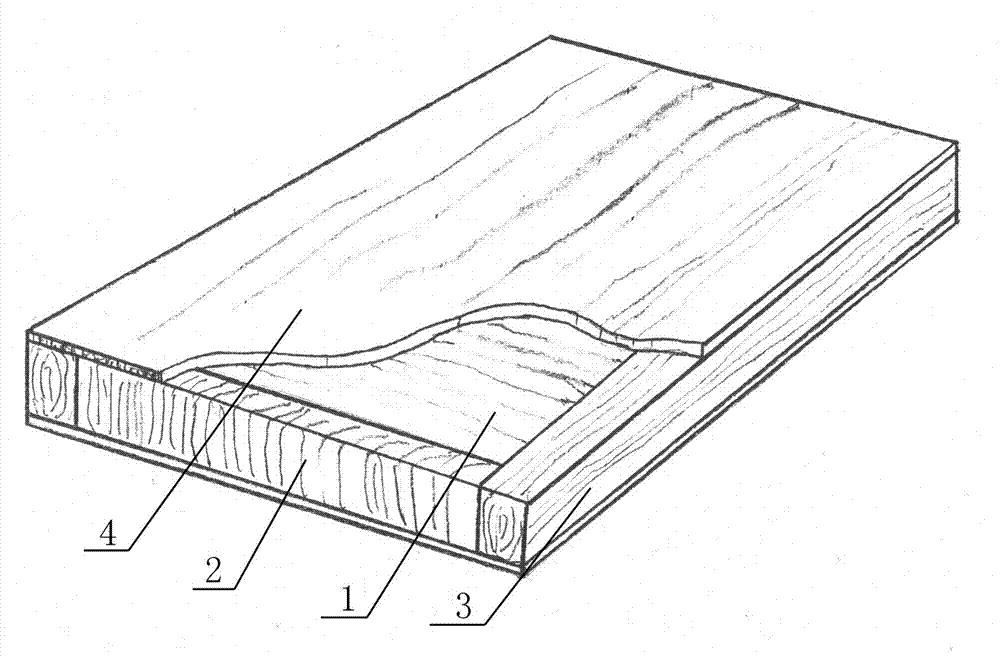

[0021] Embodiment 1, a kind of solid board, with reference to figure 1 , which is hydraulically formed by criss-cross gluing of similar woods, including a transverse-grained substrate 1 with transverse-grained surface in the middle, longitudinal-grained head plates 2 glued to both ends along the grain direction of the transverse-grained substrate 1, and on the transverse-grained substrate 1 The two sides of the cut wood grain direction are glued with longitudinal grain side seal plates 3, and the longitudinal grain seal plates 4 are glued to the upper and lower sides and cover the transverse grain substrate 1, the longitudinal head plate 2 and the longitudinal grain side seal plates 3, which constitute A structure of the present invention.

[0022] A production method of the above-mentioned solid wood board is as follows: the required surface is a transverse grain substrate 1 with transverse grain cut according to the specifications; The same longitudinal grain head plate 2; ...

Embodiment 2

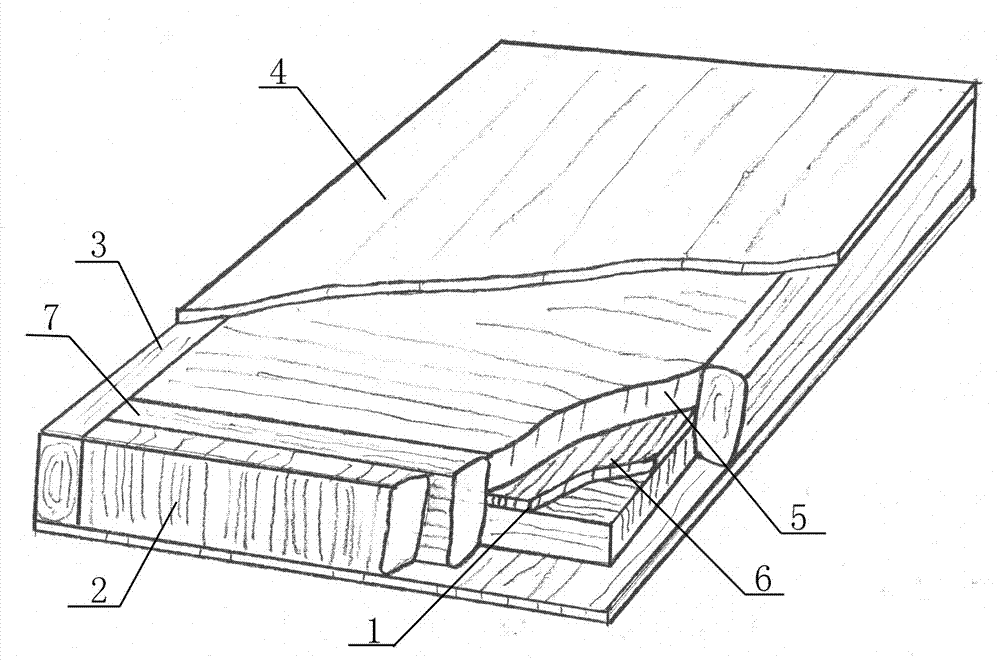

[0023] Embodiment 2, a kind of solid wood board, with reference to figure 2 , on the basis of Example 1, the transverse grain substrate 1 is formed by laminating and pressing multilayer transverse grain solid wood panels 5 and longitudinal grain solid wood panels 6 staggeredly, and its upper and lower surfaces are transverse grain solid wood panels 5 , the two ends along the grain direction of the transverse grain solid wood board 5 are glued with a transverse grain head plate 7, and the thickness of the transverse grain head plate 7 is the sum of the thicknesses of the longitudinal grain solid wood plate 6 and the transverse grain solid wood plate 5, and the others are completely the same as in Example 1. same.

[0024] A production method of the above-mentioned solid wood board is that the production method of the horizontal grain substrate 1 with a horizontal grain on the surface is to use a vertical grain solid wood board 6 and a horizontal grain solid wood board 5 to be ...

Embodiment 3

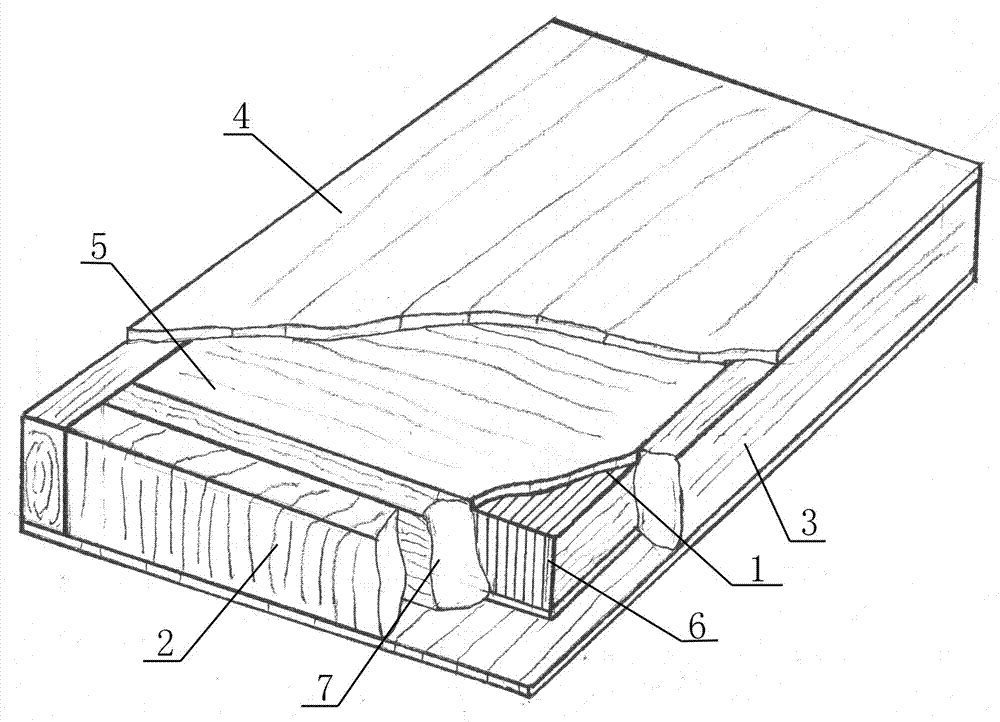

[0025] Embodiment 3, a kind of solid board, with reference to image 3 , is on the basis of embodiment 1, and described transverse grain substrate 1 is to be bonded by multi-layer longitudinal grain solid wood board 6, and the upper and lower surface of vertical longitudinal grain solid wood board 6 is bonded with transverse grain solid wood board 5 , the two ends along the transverse grain solid wood board 5 wood grain direction are glued with transverse grain head plate 7, and others are identical with embodiment 1.

[0026] A production method of the above-mentioned solid wood board is that the production method of the horizontal grain substrate 1 with a horizontal grain on the surface is to use the surfaces of a plurality of longitudinal grain solid wood boards 6 with the same specification to be bonded to each other, and the number of the longitudinal grain solid wood boards 6 Determine according to needs, then stick a horizontal grain solid wood board 5 on the upper and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap