Printed circuit board high concentration organic waste liquid and acid waste liquid treatment process

A technology for printing circuit boards and organic waste liquids, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. High cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

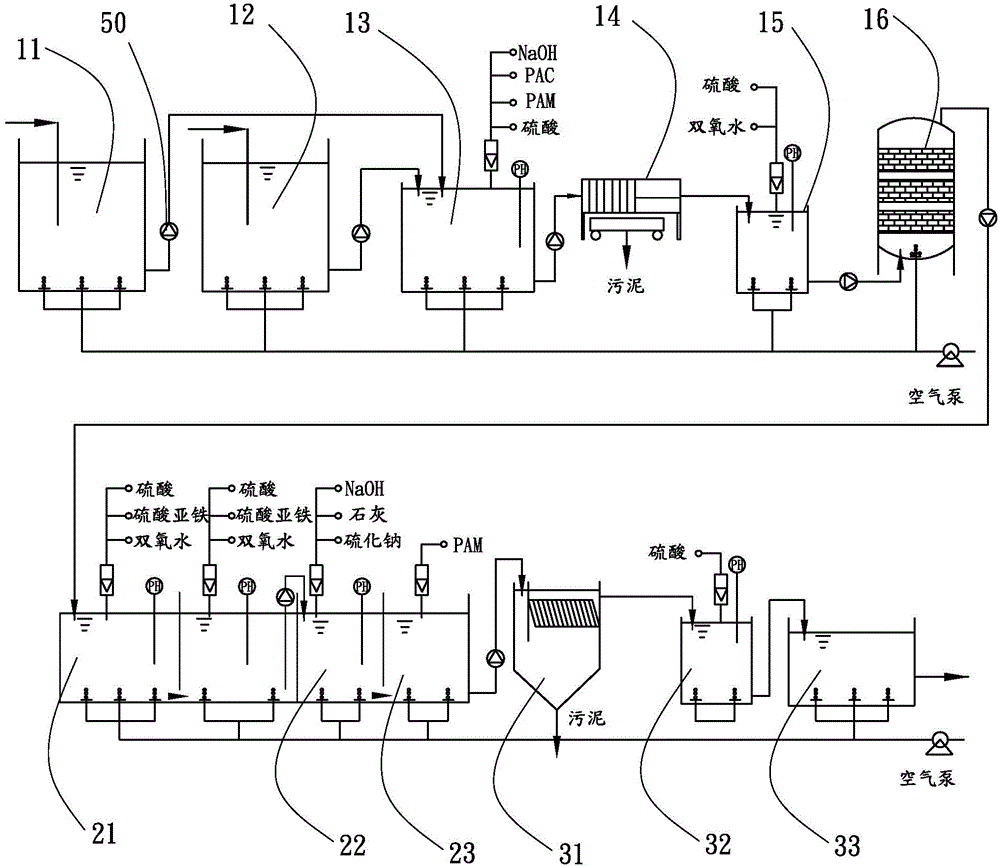

[0020] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

[0021] Please refer to figure 1 , a printed circuit board high-concentration organic waste liquid and acid waste liquid treatment process, comprising the following steps:

[0022] (1) Separately collect high-concentration organic waste liquid (developing waste liquid, film fading waste liquid, waste ink, etc.) in the circuit board industry into the organic waste water pool 12, and separately collect acidic waste liquid (pickling waste liquid, etc.) into the waste acid pool 11;

[0023] (2) Inject the high-concentration organic waste liquid from the organic waste water pool 12 and the acidic waste liquid from the waste acid pool 11 into the acid analysis pool 13 in proportion, add flocculant after adjusting the pH value of the waste water, aerate the reaction for 20-30 minutes, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com