Method using vacuum brazing device to braze aluminum alloy workpiece

A technology of vacuum brazing furnace and aluminum alloy, which is applied in the field of vacuum brazing device for aluminum and aluminum alloy workpieces, can solve the problems of low yield of aluminum alloy brazing products, difficulty in feeding and discharging salt, long production cycle, etc. Achieve the effect of improving brazing efficiency and yield, improving brazing performance and quality, and efficient and thorough removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

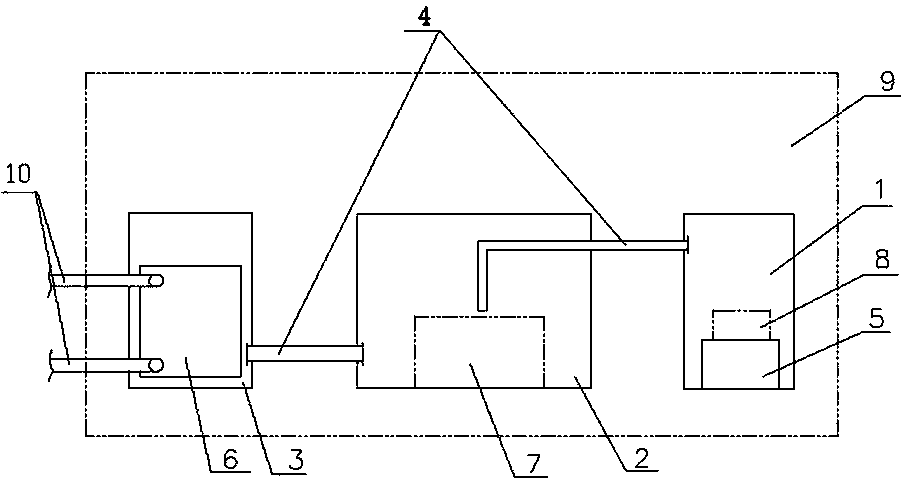

[0020] Such as figure 1 As shown, the vacuum brazing device of the present invention comprises a magnesium vapor generating chamber 1, a brazing chamber 2 and a magnesium collecting chamber 3, and a conduit is passed between the magnesium vapor generating chamber 1, the brazing chamber 2 and the magnesium collecting chamber 3 4. Sealed communication; an electric heating device 5 is set in the magnesium vapor generating chamber 1, and a collecting copper net 6 with a cold water pipe is set in the magnesium collecting chamber 3.

[0021] The method for brazing aluminum alloy workpieces using the vacuum brazing device of the present invention will be described in detail below by taking an aluminum alloy radiator with a complex brazing structure as an example. The specific operation steps are as follows:

[0022] The first step is to clean the surface of the aluminum alloy radiator 7 to be brazed with dilute hydrochloric acid or sodium hydroxide aqueous solution to remove surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com