Micro-field-of-view bilateral dynamic in-situ micro-torsion material mechanical property tester

A technology of torsion materials and microscopic field of view, applied in scientific instruments, analytical materials, instruments, etc., can solve the problems of little or no consideration of the accuracy of the position of the specimen, restrictions on the in-depth and development of research, and lack of test content. Achieve the effect of stable test process, compact structure and small torsion angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

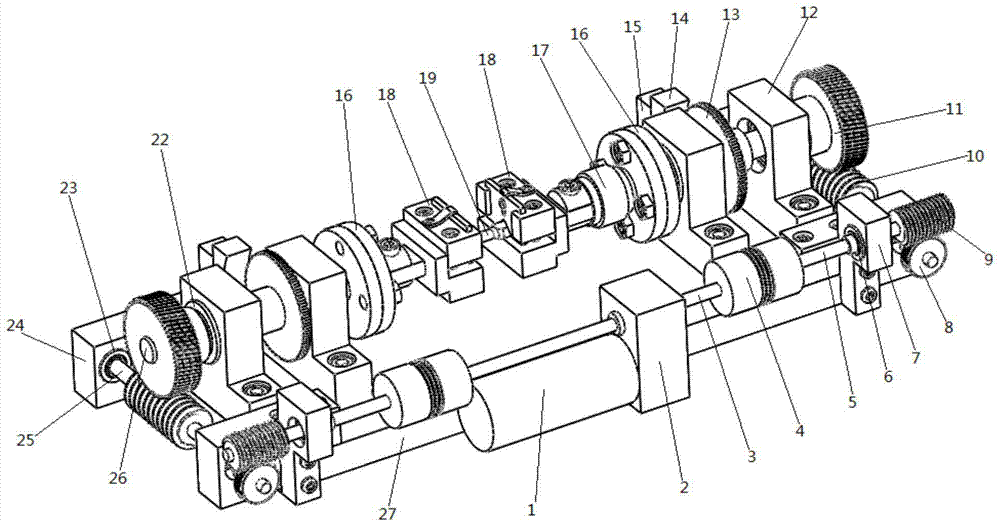

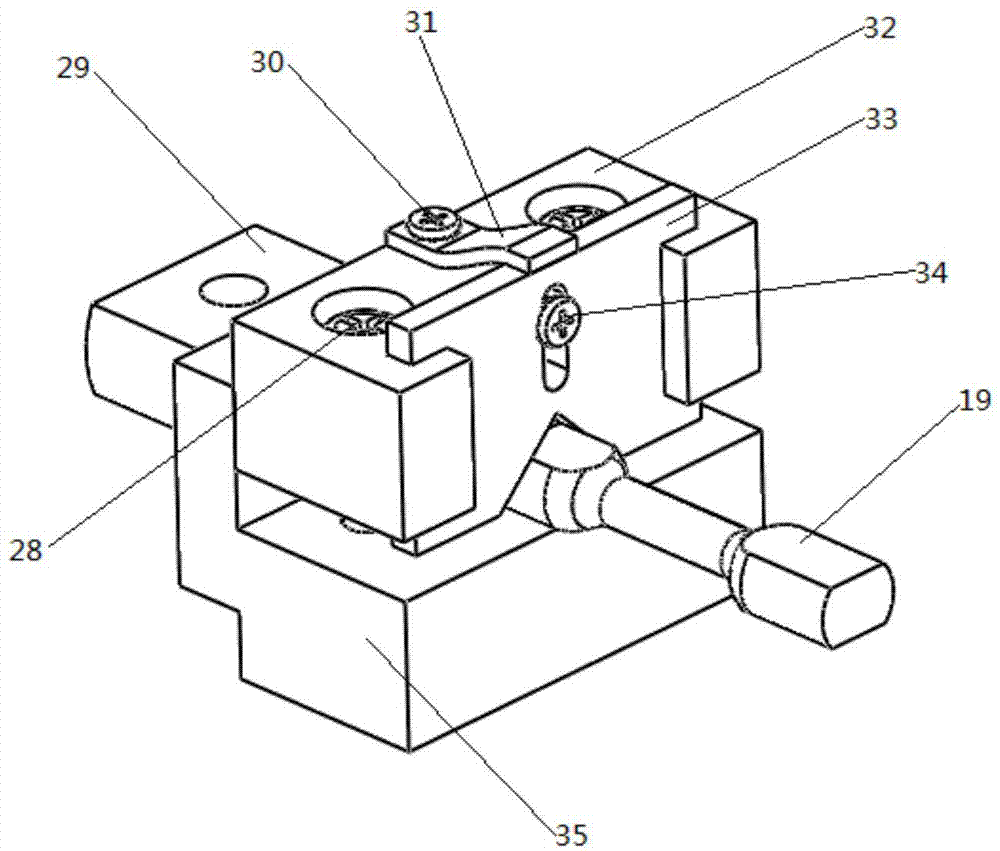

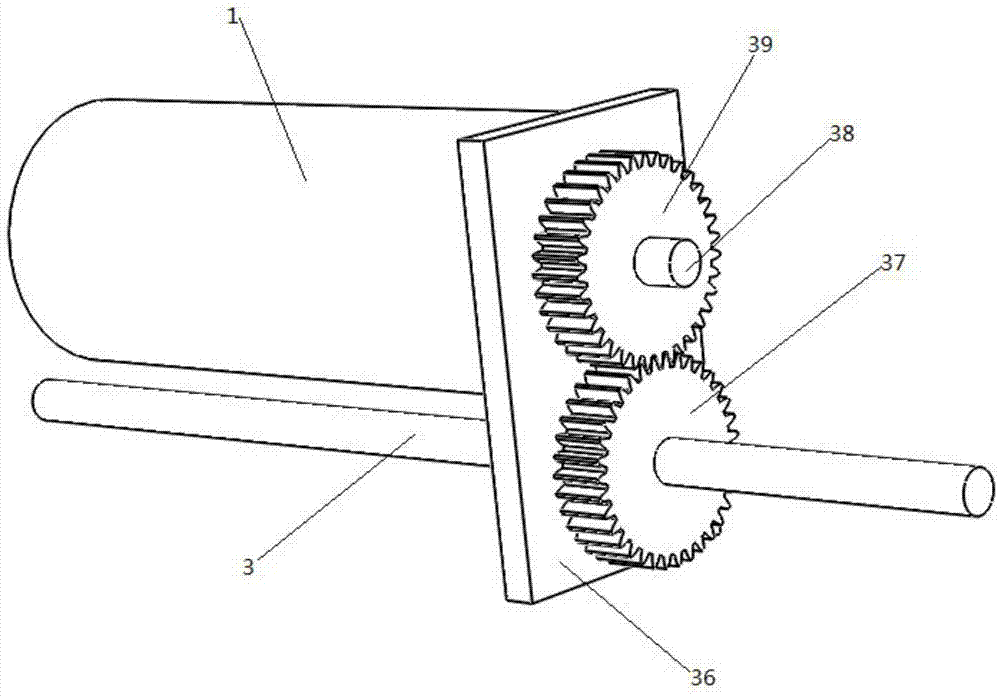

[0017] The invention includes a base, a DC servo motor, a gearbox, an elastic coupling, a main shaft, and a fixture. The axes of the two main shafts are on the same straight line, and the two main shafts are equipped with fixtures, torque sensors, flanges, reading head connecting frames, circular grating reading heads, and circular grating scales in sequence from the front section to the rear. Shaft connections gain torque. A further technical solution is that the transmission device is a worm gear pair consisting of a high-speed worm gear and a low-speed worm gear, the high-speed worm is connected with an elastic coupling, and the low-speed worm gear is installed at the rear end of the main shaft. The fixture is composed of an upper platen and a lower platen. The upper platen and the lower platen are connected by clamping bolts. There is a positioning groove at the front end of the upper platen. There is a positioning piece in the positioning groove. The lower end of the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com