A fully digital high-precision three-dimensional magnetic flux leakage signal acquisition device

A fully digital, signal acquisition technology, applied in the direction of material magnetic variables, etc., can solve the problems of sensor time difference, magnetic sensor coincidence at one point, large position error, etc., to achieve easy use and maintenance, elimination of gating time delay, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

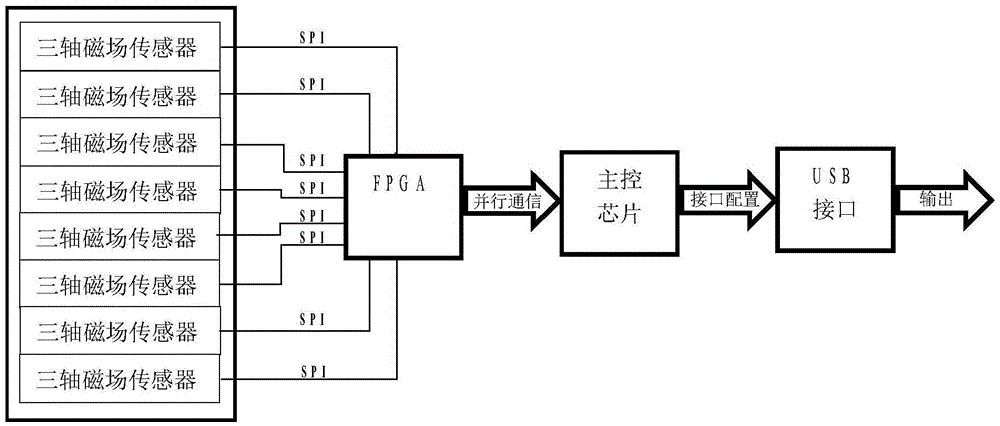

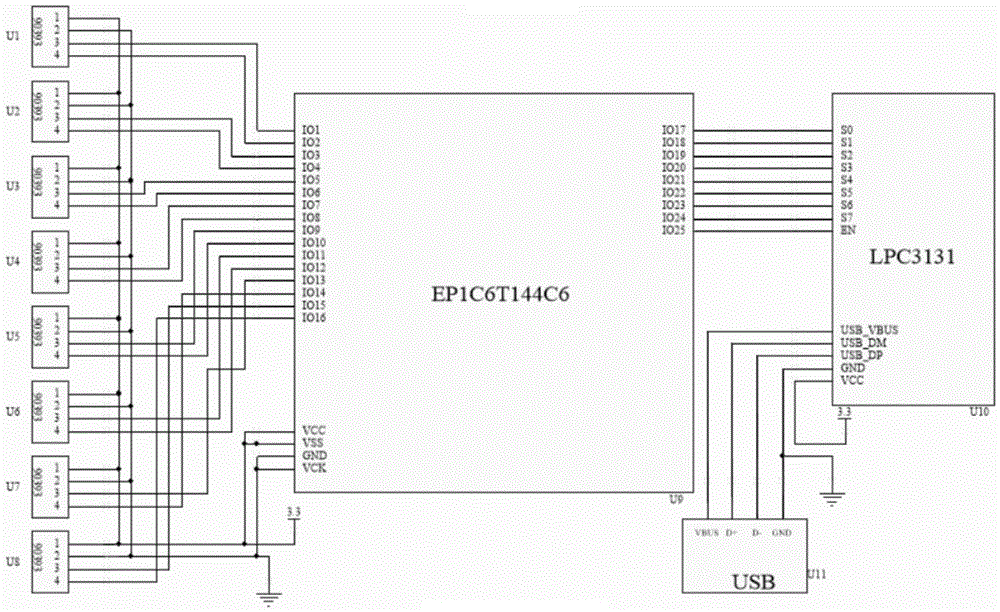

[0024] refer to figure 1 , a full-digital high-precision three-dimensional magnetic flux leakage signal acquisition device, including 8 three-axis magnetic field sensors, the signal output of the 8 three-axis magnetic field sensors and the input connection of the FPGA, the output of the FPGA and the input connection of the main control chip, the main control The output of the chip is connected to the USB interface, and the USB interface sends the data through an external cable.

[0025] Each of the three-axis magnetic field sensor chips has an independent gate port, which can sense the three-dimensional magnetic field strength, directly measure the magnetic field strength values in three mutually perpendicular directions, and directly output digital quantities externally using the SPI data communication protocol.

[0026] The FPGA has abundant IO i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com