Method for improving precision of built-in real-time clock of electric energy meter MCU

A technology of real-time clock and electric energy meter, applied in measuring devices, measuring electrical variables, instruments, etc., can solve the problems of accuracy influence, timing error, and the inability to calibrate the compensation amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

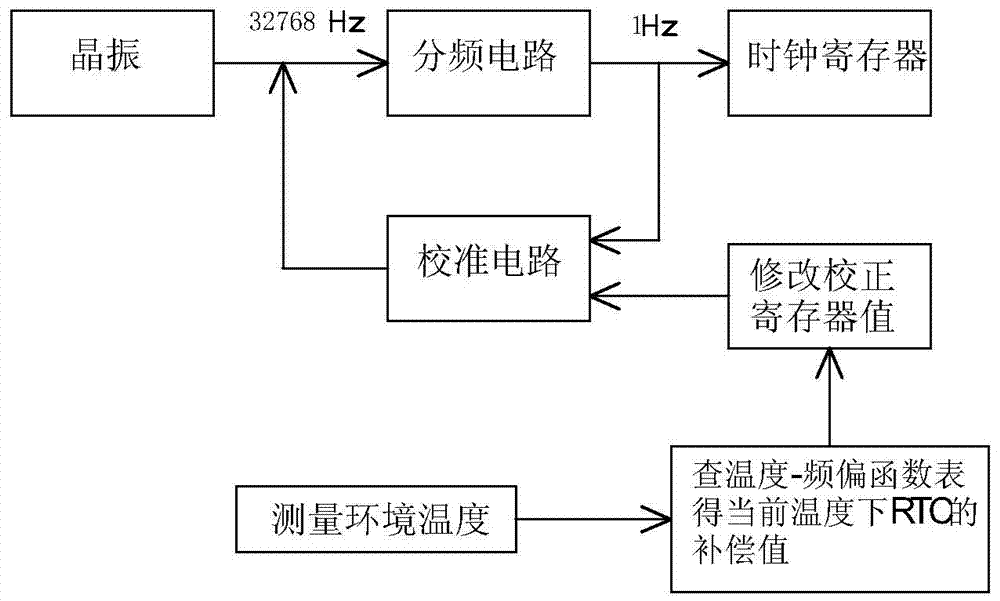

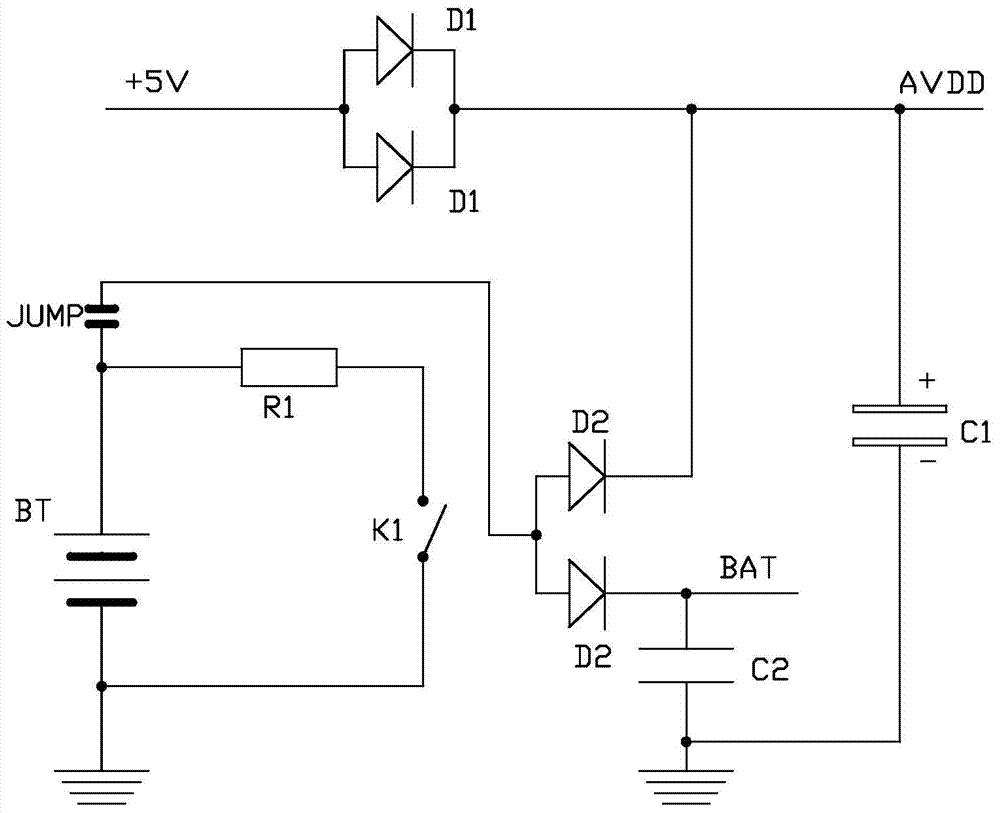

[0032] The present invention as Figure 1-4 Shown: described watt-hour meter comprises MCU, crystal oscillator and power management unit, and described power management unit connects battery and regulated power supply by power supply circuit;

[0033] It includes the following steps: calculating the compensation amount and correcting the clock;

[0034] The calculation of the compensation amount is carried out according to the following process:

[0035] 1) Measure the frequency deviation of the actual crystal oscillator at different temperatures;

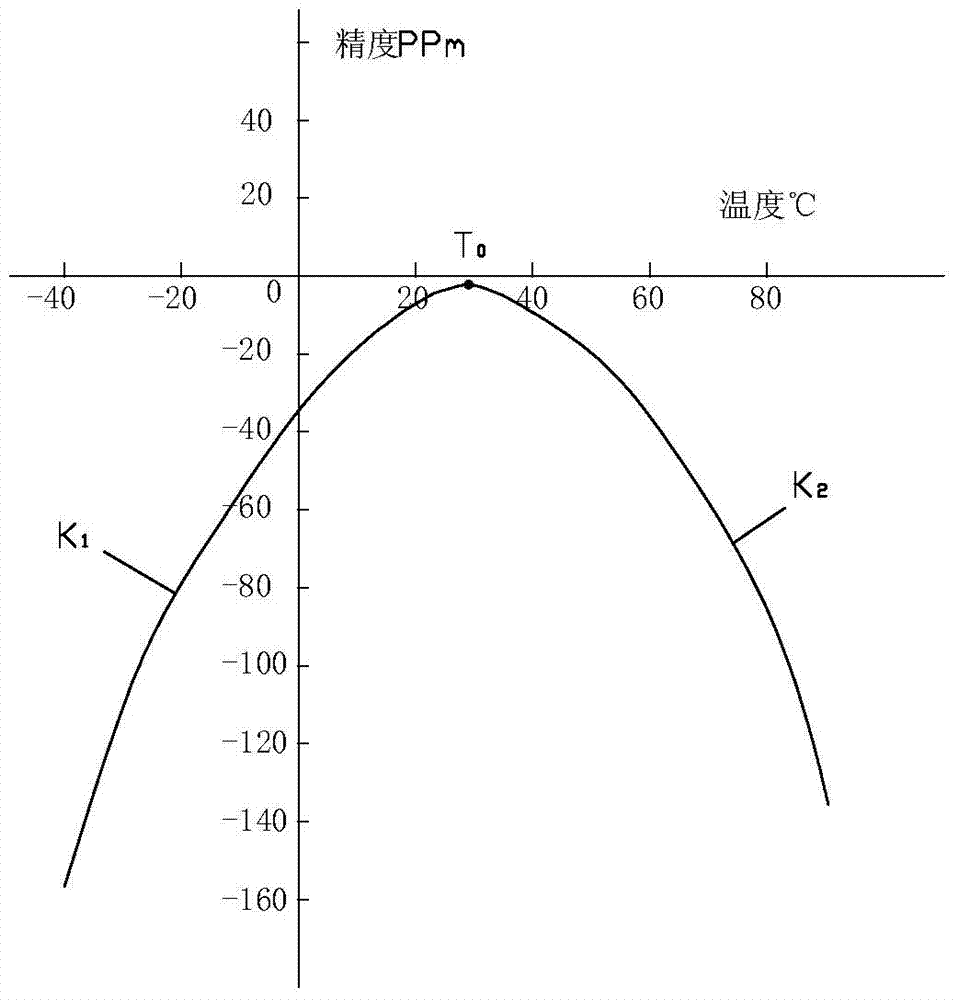

[0036] 2) Draw a sketch of the temperature-frequency deviation curve and find out the turning temperature T 0 ;

[0037] 3), respectively for T 0 The frequency deviation measured on both sides is used for curve fitting to obtain the corresponding curvature constant.

[0038] 3.1), when T0 When , the curvature constant K of the temperature and frequency offset function is fitted according to the measured value 1 value,

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com