Die forging press stroke improved compensation method

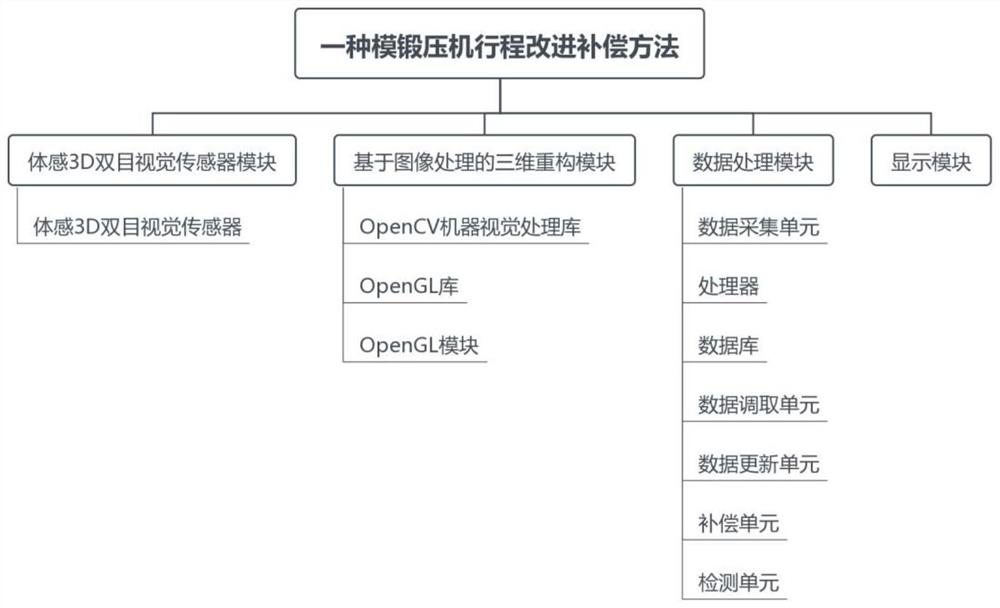

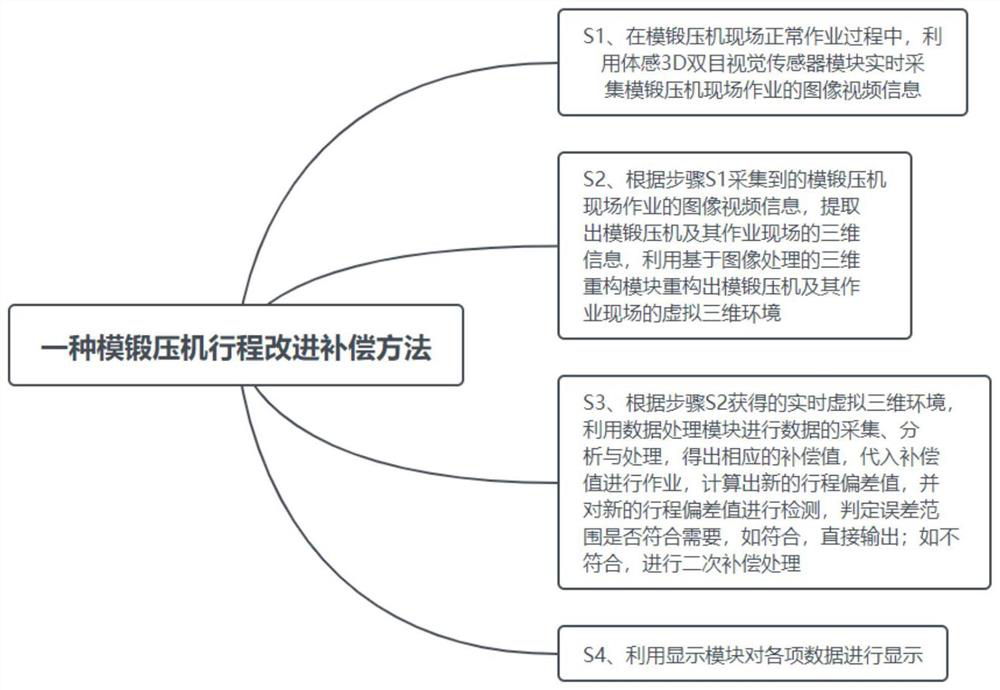

A technology of die forging press and compensation method, which is applied in the direction of the driving device of the forging press, can solve the problems of deviation between the actual displacement of the press and the expected displacement, the axial deformation of the column of the press, and the lack of precision of the die forging, so as to prevent the accuracy from being affected. loss, reduction of repair times, and precise compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

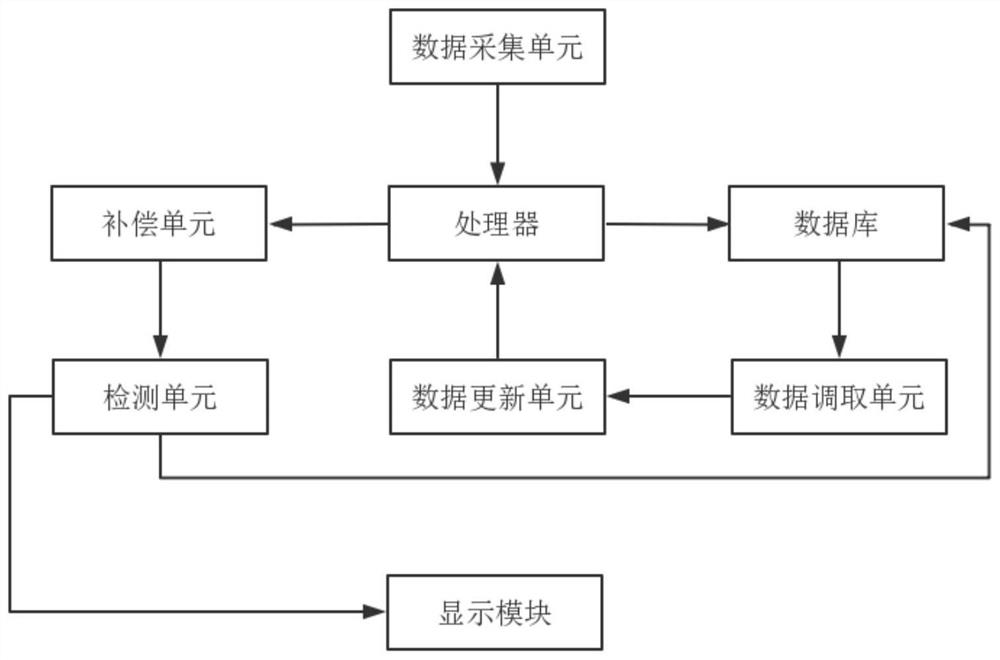

Method used

Image

Examples

Embodiment 1

[0104] Use the somatosensory 3D binocular vision sensor and the 3D reconstruction module based on image processing to reconstruct the virtual 3D environment. With the worktable as the center, the x-axis is established in the left and right parallel direction of the worktable, the y-axis is established in the front and back direction of the worktable, and the up-down direction of the worktable Establish the z-axis, take mm as the unit, use the data acquisition unit to collect the position data of the movable beam H={0.1,0.2,0.5} under different clamping pressures,

[0105] Define the degree of extrusion of the workbench backing plate into grades 0-3, including:

[0106] Level 0: no extrusion at all;

[0107] Level 1: Extrusion is not greater than 0.1mm;

[0108] Level 2: Extrusion is not greater than 0.5mm;

[0109] Level 3: extrusion greater than 0.5mm;

[0110] Defining the degree of deformation of the press pillar is divided into 0-3 grades, including:

[0111] Level 0: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com