Automatic focusing equipment of high-pixel module

An auto-focusing, high-pixel technology, applied in instrumentation, installation, optics, etc., can solve problems such as poor focusing effect and low manual operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

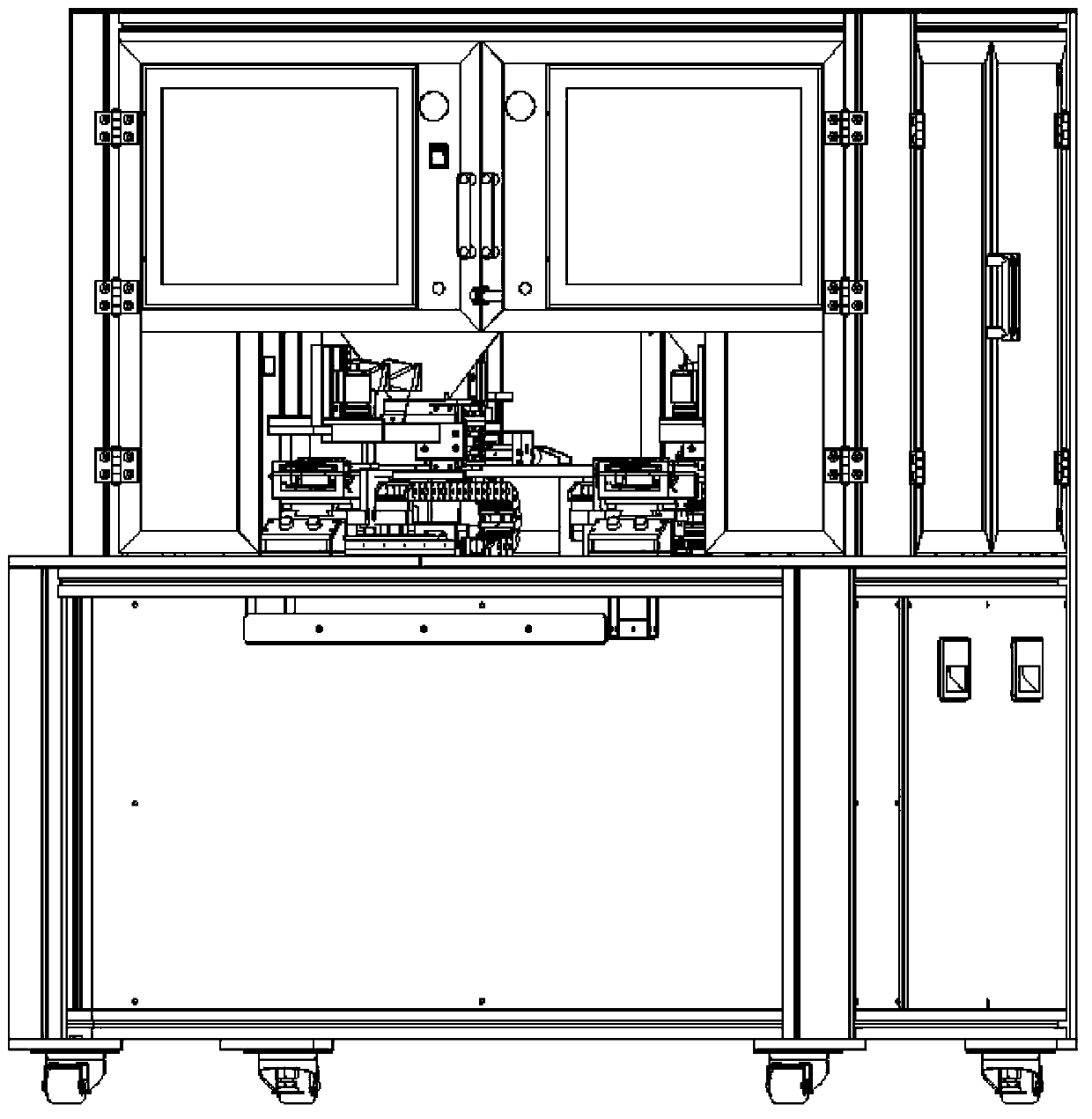

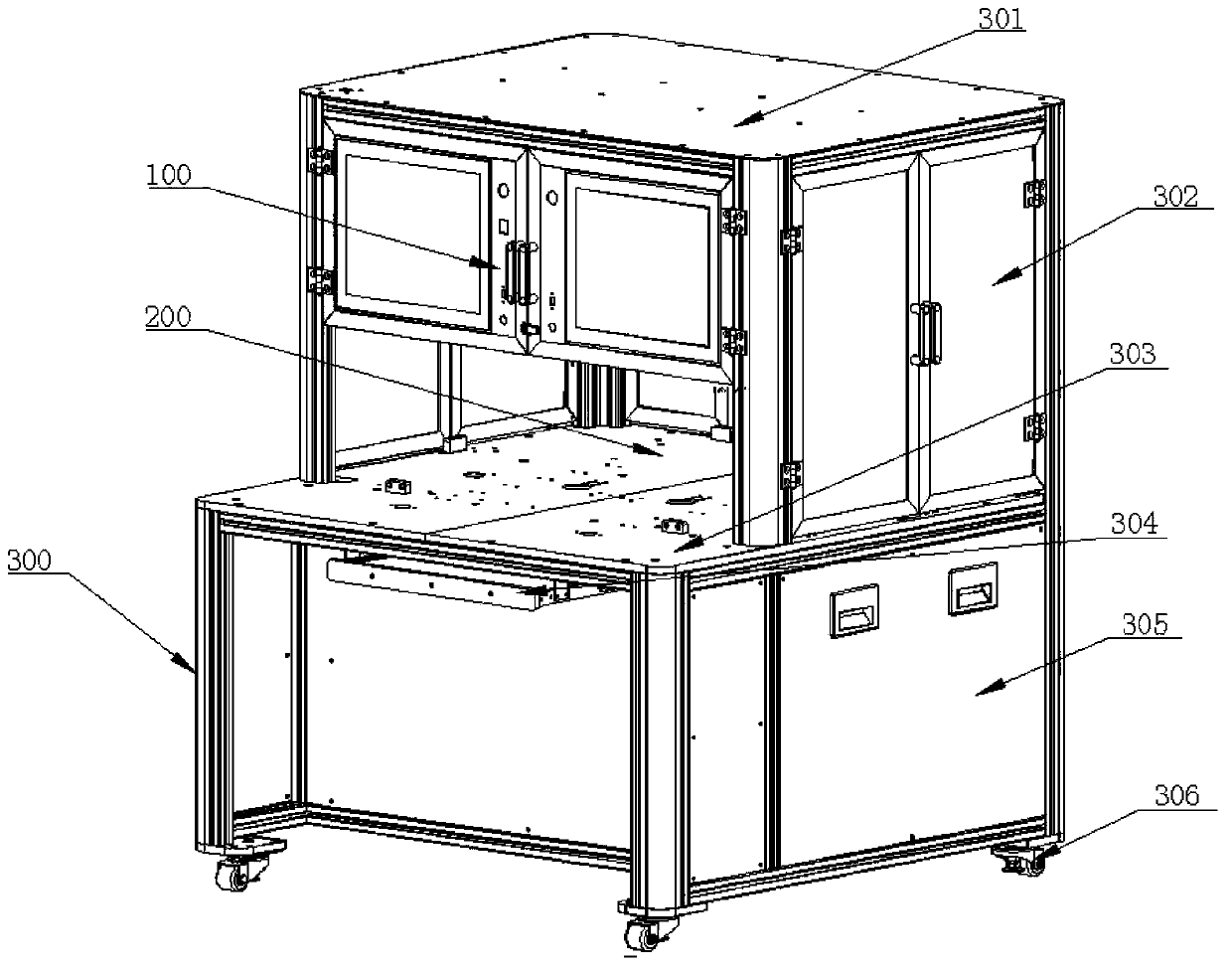

[0024] Such as figure 1 with figure 2 As shown, the automatic focusing device of the high pixel module provided by the present invention is composed of a control panel 100 , a focusing test area 200 and a workbench frame 300 .

[0025] 301~306 parts are installed on the described workbench frame 3, and top cover 301 is installed on its top; 3 double-opening black glass side doors 302 are installed on the upper half of the frame, which can avoid external light while conveniently monitoring the running state of the equipment. interference; two worktables 303 are placed in the middle as a platform to support two focusing test stations; a keyboard tray 304 is provided at the front and bottom of the worktable 303 to place keyboards; iron plate side doors are installed around the lower half of the frame 305, used to protect the internal electrical modules and wiring of the equipment; the bottom is four casters 306, used to move and fix the equipment.

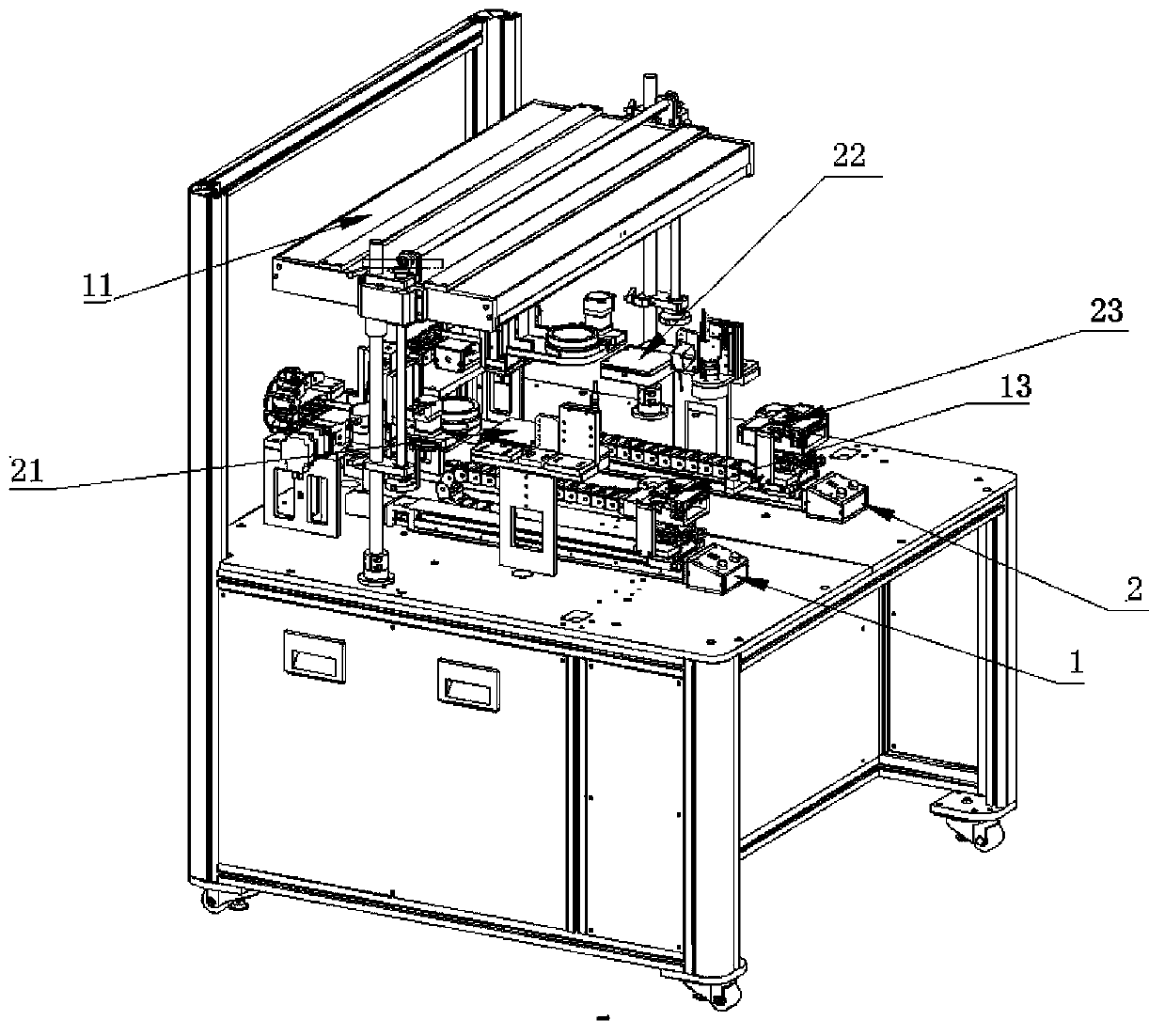

[0026] Such as image 3 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com