Focusing device based on inner coaxial shaft and focusing method based on inner coaxial shaft

A focusing device, coaxial technology, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of low processing efficiency and poor position consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

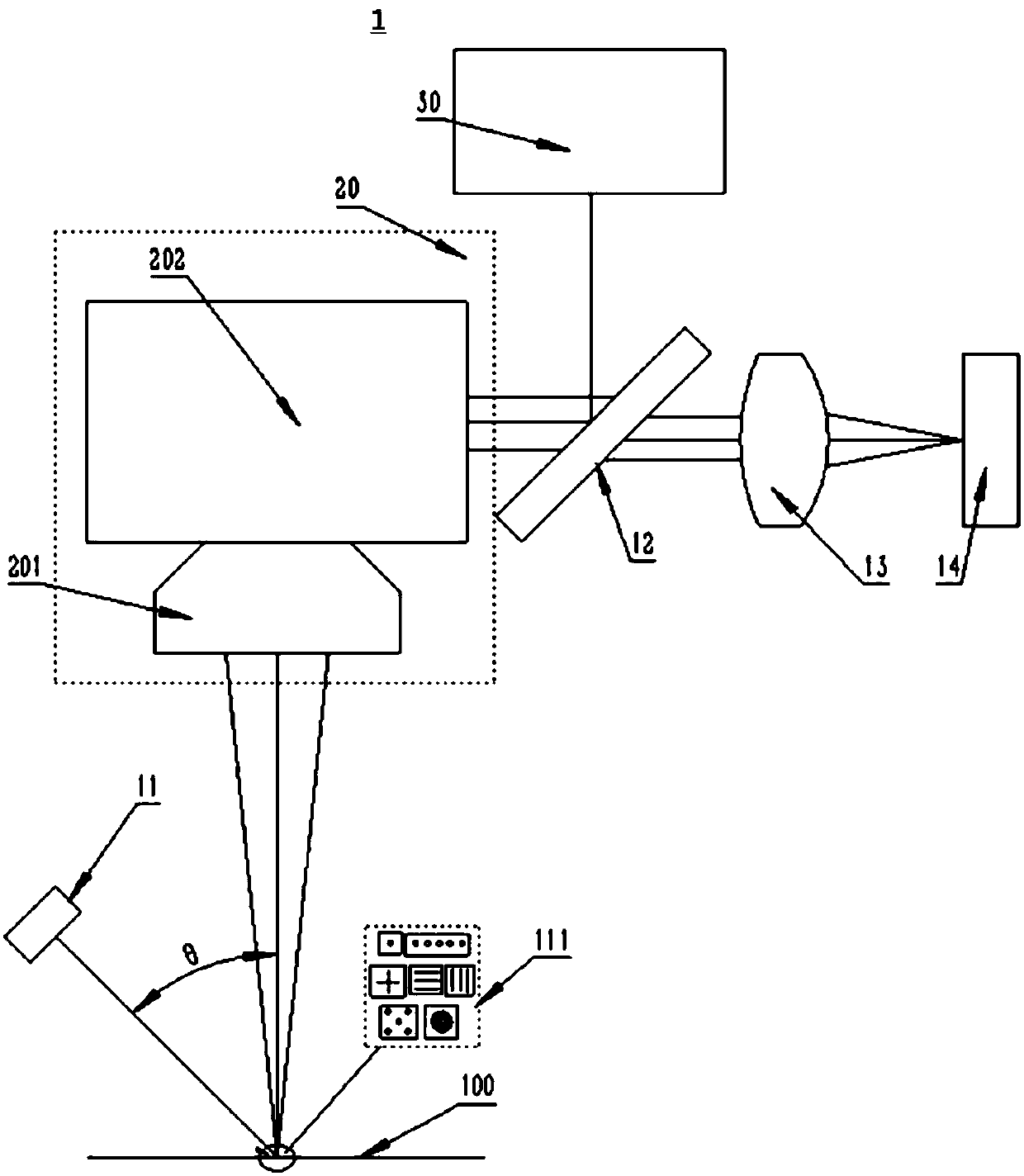

[0046] figure 1 A schematic structural diagram of an inner coaxial-based focusing device 1 provided by an embodiment of the present invention.

[0047] Please refer to figure 1 , the present embodiment provides a focusing device 1 based on an inner coaxial, the device includes a light source 11, a galvanometer focusing system 20, a beam splitter 12, a laser 30, a camera lens 13 and a sensor 14;

[0048] The light source 11 is set to output a light beam to the workpiece. The beam irradiates the surface of the workpiece to form a beam state 111. The image information of the beam state 111 is transmitted to the beam splitter 12 through the galvanometer focusing system 20, and the image information is transmitted to the camera through the beam splitter 12. lens 13 and sensor 14;

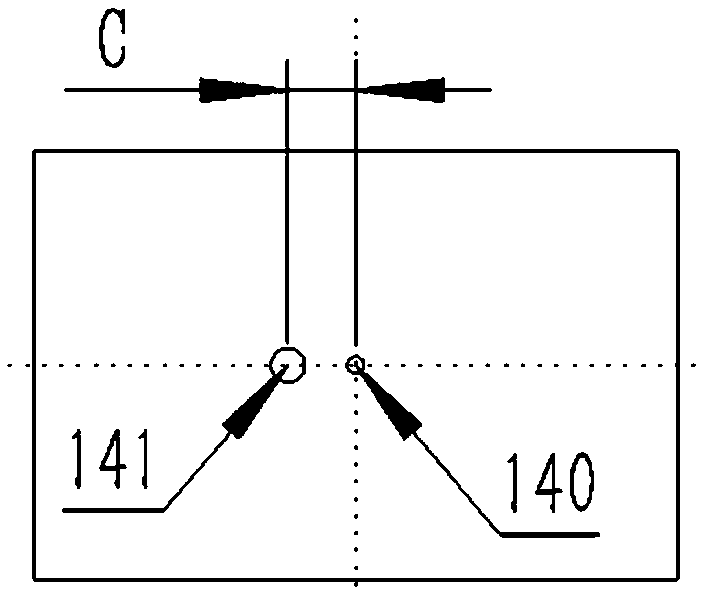

[0049] The camera lens 13 is configured to transmit the image information of the light beam to the sensor 14, and the sensor 14 receives the image information and obtains the position of the center of ...

Embodiment 2

[0066] This embodiment also provides a focusing method based on internal coaxial, using the above-mentioned focusing device 1 based on internal coaxial, the structure of focusing device 1 based on internal coaxial can refer to embodiment 1, the internal coaxial based The focusing method of the axis has all the functions of the focusing device 1 based on the inner coaxial.

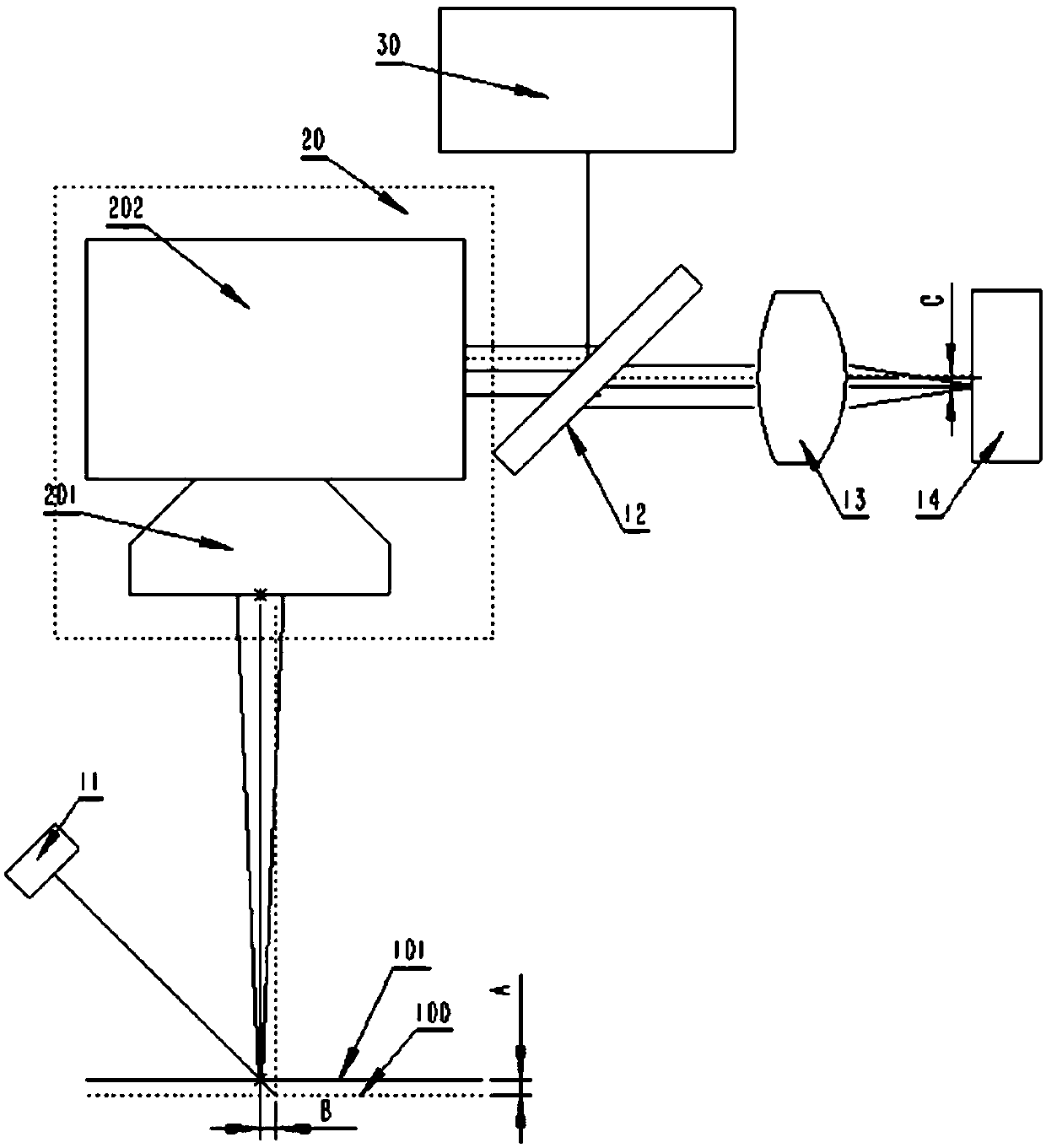

[0067] The method includes pre-adjusting the distance between the galvanometer focusing system 20 and the workpiece, finding the laser focal plane 100, turning on the light source 11 to output a beam of light that is at an angle θ with the main optical axis of the galvanometer focusing system 20 to the workpiece, and the image information of the beam passes through the field in sequence. mirror 201, vibrating mirror 202, and pass through the beam splitter 12, then arrive in the sensor 14 through the camera lens 13, and locate by software, the image position of the light beam on the sensor 14 is recorded as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com