Rotary blade-box rub-impact force determining method

A determination method and technology of rotating blades, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as blade bending, system influence, forced vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

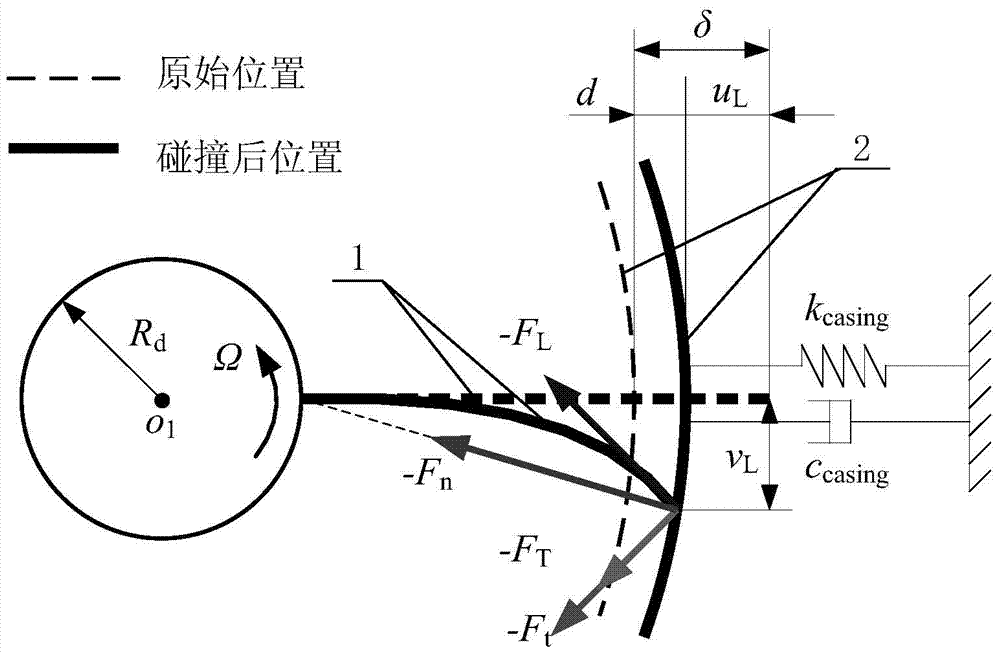

[0085] A method for determining frictional force of rotating blade-casing, comprising the steps of:

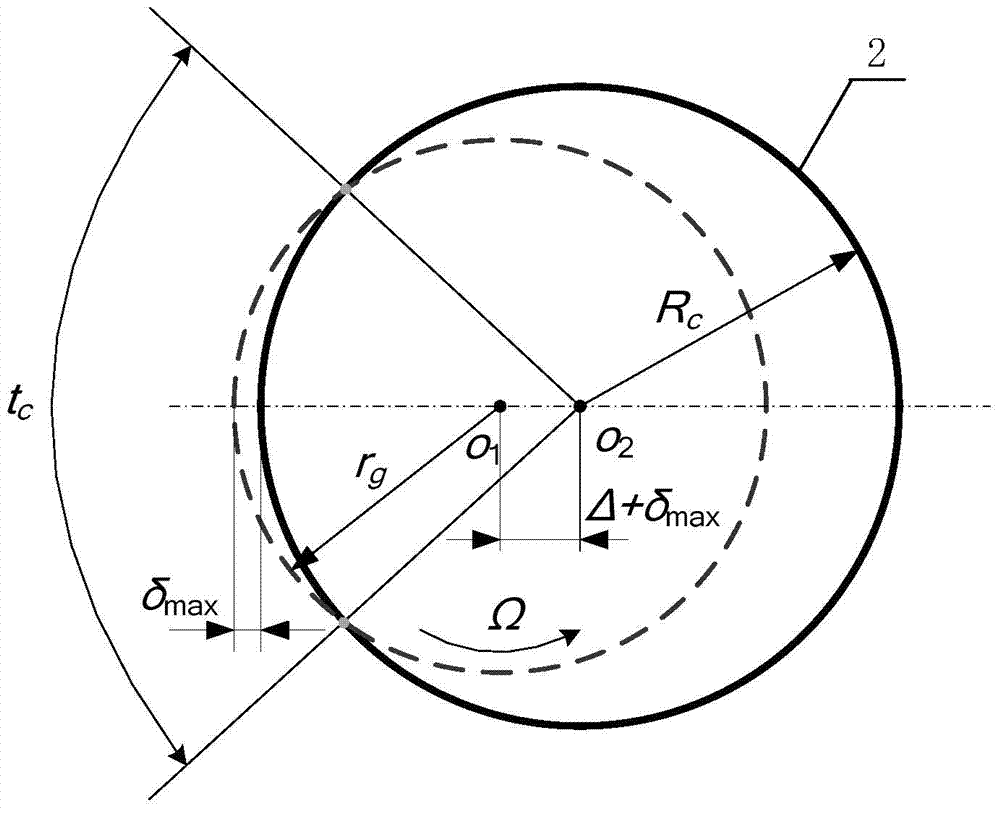

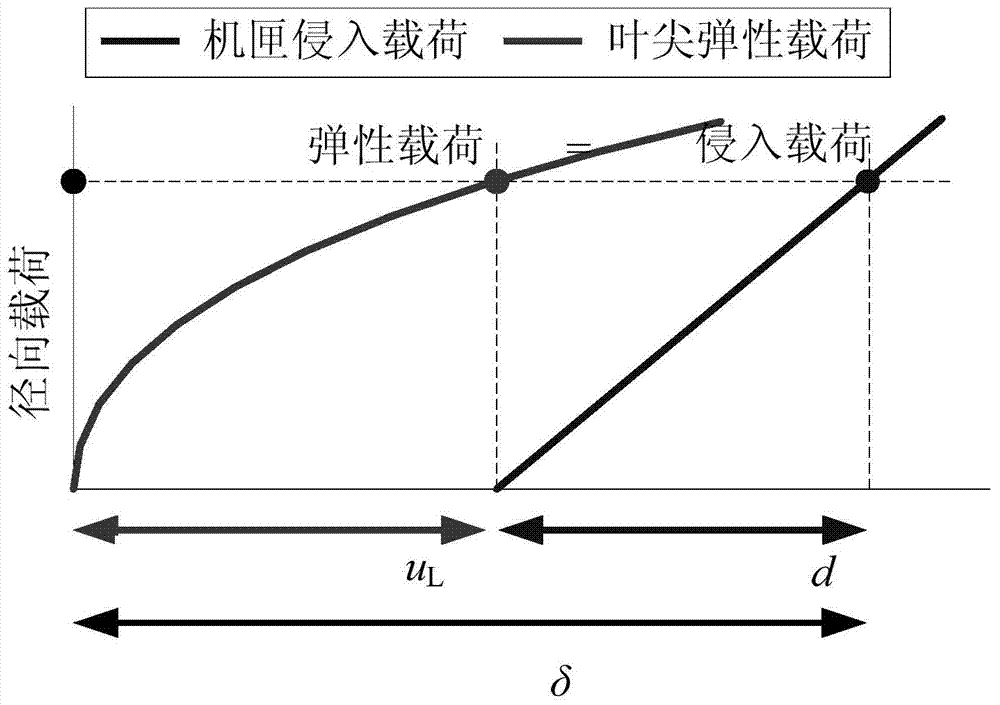

[0086] Step 1: Measure the geometric dimensions and operating conditions of the blade and casing, including the length L of the blade, the width b of the blade, the thickness h of the blade, and the radius R of the blade disc d , casing radius R c , the minimum distance c between the blade tip and the inner wall of the casing min and speed Ω;

[0087] Step 2: According to the law of conservation of mechanical energy, the functional equation of the blade and casing at a certain moment is established:

[0088] Assume that the blade satisfies the conservation of mechanical energy during a certain time when the blade is in contact with the casing:

[0089] u e + U c =W (4)

[0090] in:

[0091] u e is the bending deformation energy of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com