Saddle-type vehicle

A straddle-type, vehicle technology, applied to vehicle parts, motorcycles, bicycles, etc., to achieve the effect of reducing weight and cost, reducing weight and cost, and improving assembly workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

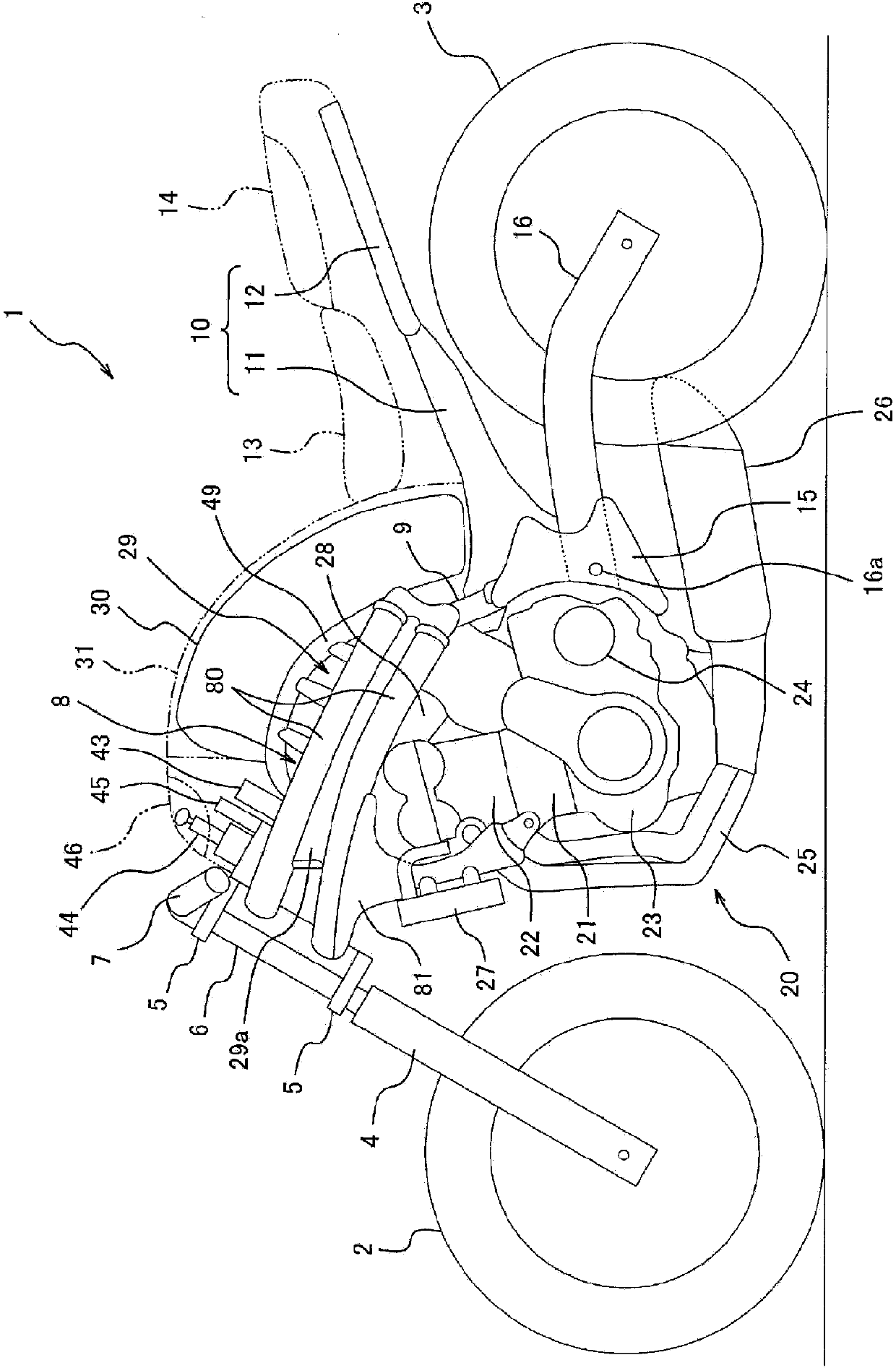

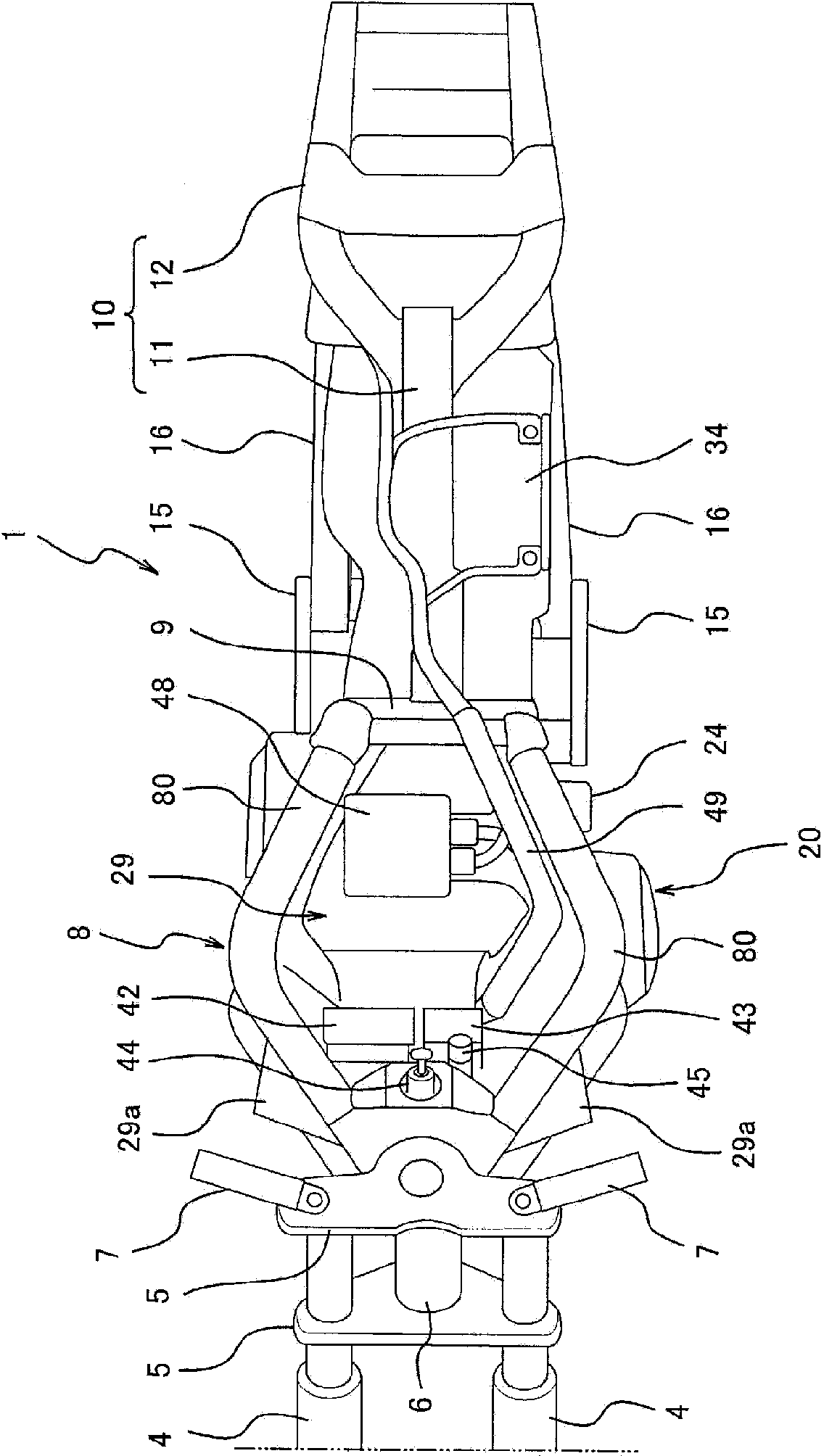

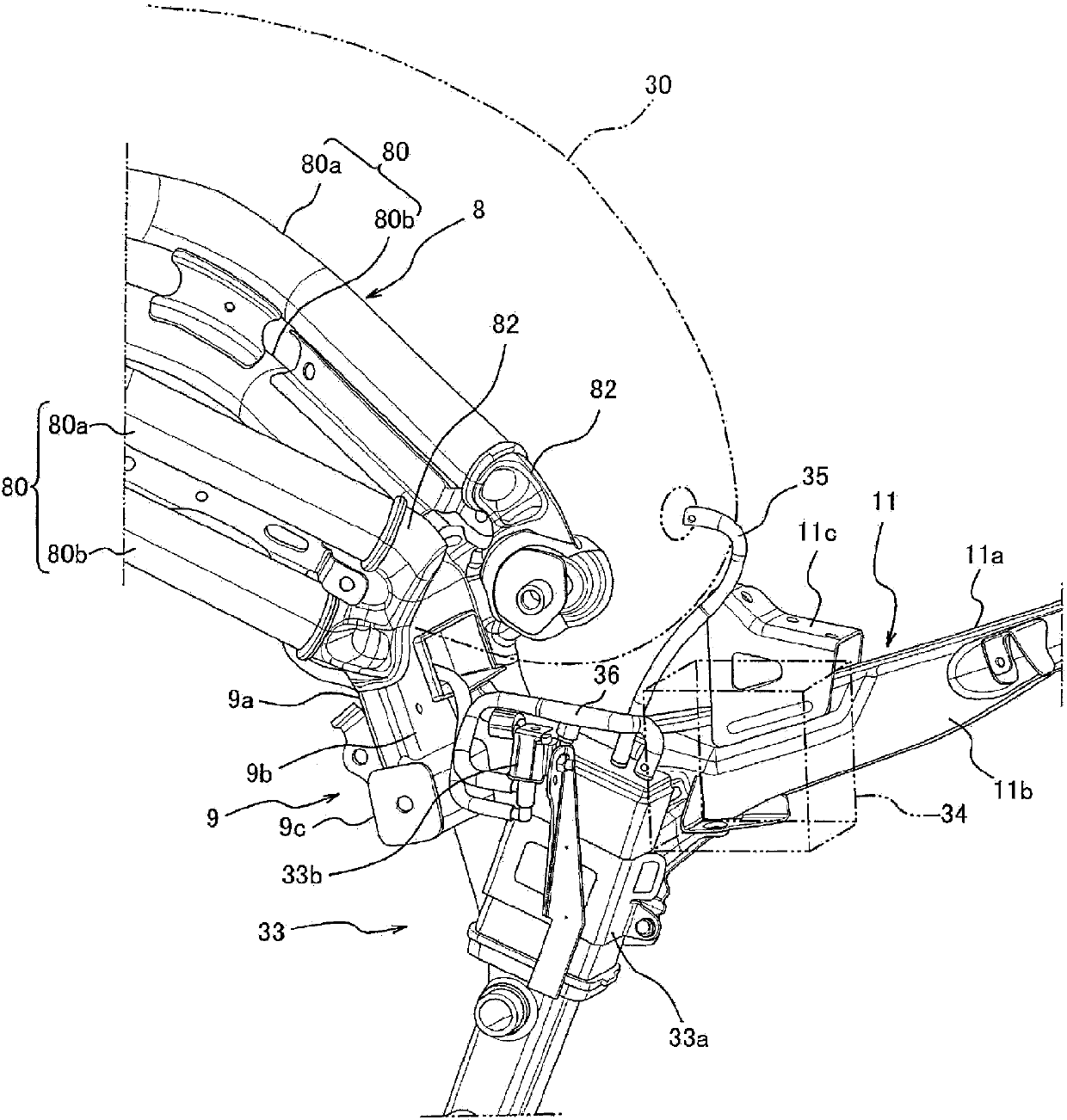

[0036] Hereinafter, a motorcycle 1 (a straddle-type vehicle) according to an embodiment of the present invention will be described with reference to the drawings. figure 1 It is a left side view showing a schematic structure of the motorcycle 1 with lamps, fairings, etc. removed, figure 2 It is a top view with the fuel tank and seats removed. In addition, the concept of direction used in the following description is based on the direction seen by a driver (user) riding a motorcycle.

[0037] The motorcycle 1 includes a front wheel 2 as a driven wheel, and a rear wheel 3 as a driving wheel. The front wheel 2 is rotatably supported by the lower ends of a pair of left and right front forks 4 extending approximately in the vertical direction, and the upper portion of the front forks 4 is supported by a steering shaft (not shown) via a pair of upper and lower brackets 5 . The steering shaft is inserted and rotatably supported in a head pipe 6 constituting a part of the body fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com