Seamless bending processing technology for aluminum alloy sections

An aluminum alloy profile and seamless technology, which is applied in the technological field of 90° seamless bending of aluminum alloy profiles, can solve the problems of difficult size control, unsightly appearance, and low product qualification rate, and achieve the effect of good reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

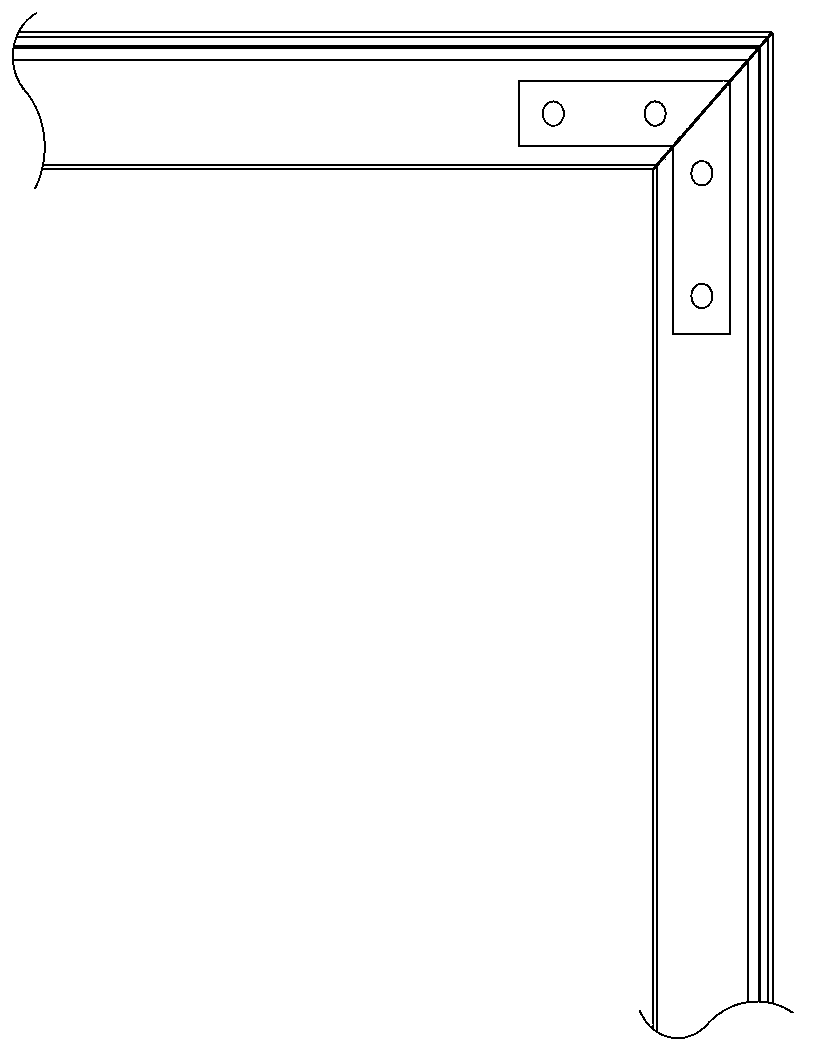

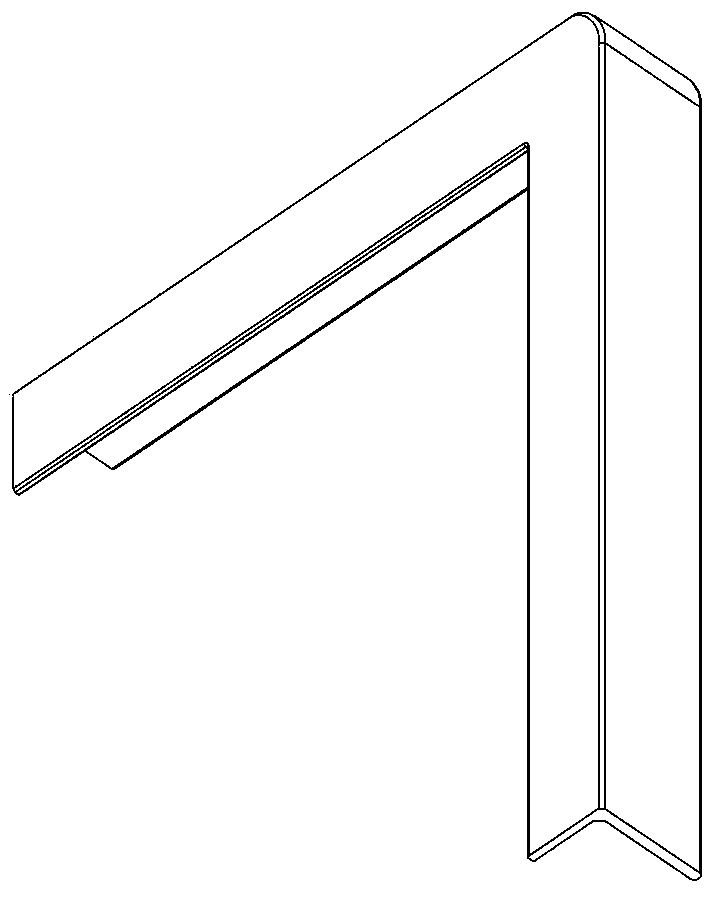

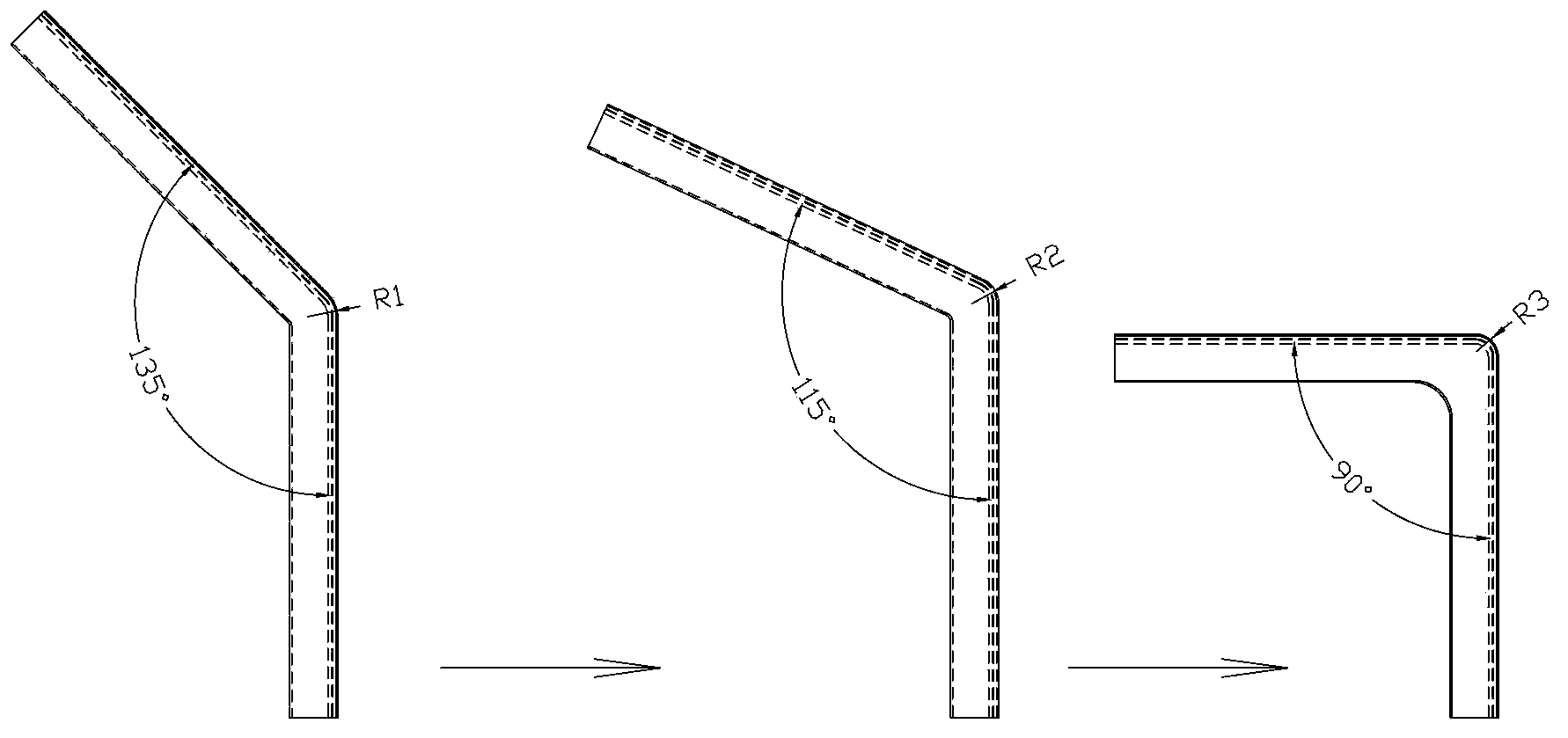

[0013] Such as figure 2 , image 3 The 90° bending process of the aluminum alloy profile of the present invention is to bend the two perpendicular surfaces of the aluminum alloy profile along its deformation apex, one surface is compressed and the other surface is stretched, and the bending is at a right angle.

[0014] The 90°bending process of aluminum alloy profile is to use the die extrusion method to make each surface of the bending part of the aluminum alloy profile uniform in force and uniform in deformation, and then cut off the extrusion flash.

[0015] The die extrusion method is divided into three steps. The actual radius of the outer arc of the 90-degree angle top that needs to be twisted and finally formed is set as R3 and the specific R3 value can be confirmed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com