Multifunctional plate shearing machine

A shearing machine, multi-functional technology, applied in the direction of shearing device, shearing machine equipment, accessories of shearing machine, etc., can solve the problems of inconvenient operation, manual movement, increase the labor intensity of operators, etc. various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

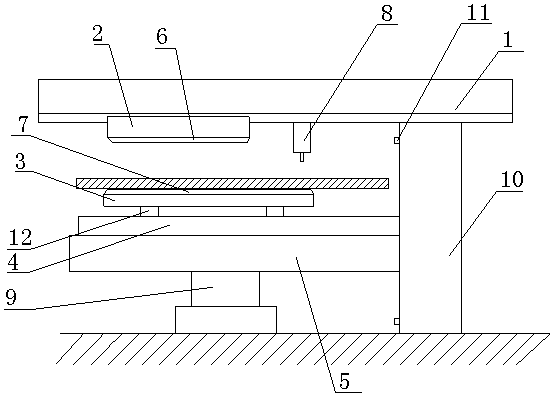

[0013] Such as figure 1 As shown, the multifunctional plate shearing machine of the present invention includes a bed 1, a shear support area 4 and a workbench 5. The bed 1 is provided with an upper knife rest 2 and a lower knife rest 3, and the upper knife rest 2 is located on the bed 1 above, the upper knife rest 2 is equipped with upper scissors 6, the upper knife rest 2 slides back and forth on the bed 1, the lower knife rest 3 is fixed on the cutting support area 4, and the lower knife rest 3 is equipped with lower scissors 7, The lower tool holder 3 slides back and forth on the shearing support area 4 , the shearing support area 4 is fixed on the workbench 5 , and a drill bit 8 for drilling is also arranged above the bed 1 .

[0014] The workbench 5 is fixed on the ground through the lifting column 9, and moves up and down through the lifting column 9, so that the height of the workbench 5 can be adjusted up and down.

[0015] The column 10 of the bed 1 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com