Nut feeding device

A feeding device and nut technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of reducing economic benefits, increasing production costs, reducing product qualification rate, etc., to increase economic benefits, improve production efficiency, reduce The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

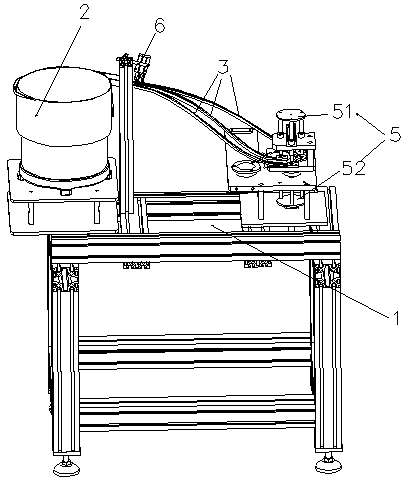

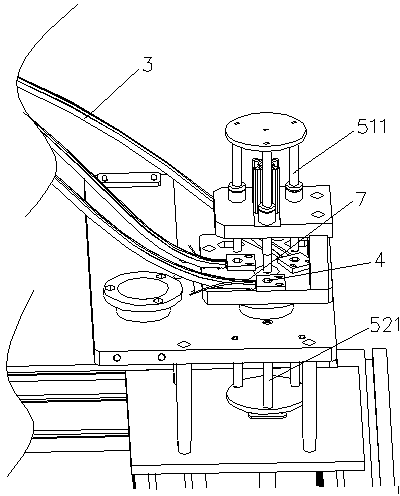

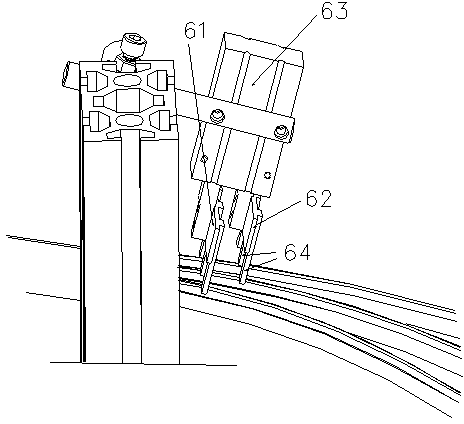

[0030] like figure 1 ,like figure 2 and as image 3 As shown, a nut feeding device includes a workbench 1 on which a vibrating plate 2, a guide rail 3, a station to be processed 4 and nuts are put into the product through the station to be processed 4 One end of the guide rail 3 is connected to the vibrating plate 2, and the other end is connected to the conveying mechanism 5; between the vibrating plate 2 and the conveying mechanism 5, control guide rails 3, The quantitative feeding mechanism 6 for quantitatively conveying nuts also includes an automatic control device (not shown), which is electrically connected to the conveying mechanism 5 and the quantitative feeding mechanism 6 respectively.

[0031] The number of the stations 4 to be processed is consistent with the number of the guide rails 3, and the nuts are transported to the stations 4 to be processed by the guide rails 3, so that each station 4 to be processed has a corresponding guide rail 3 for one-to-one tran...

Embodiment 2

[0041]The rest are the same as the above-mentioned embodiment, the difference is that one nut needs to be conveyed on the product, then the upper thimble 511 is a group, the lower thimble 521 is a group, and the number of the retaining pieces 64 is the same as that of the guide rail 3 The quantity is the same, and a group is also required. Through this technical scheme, it can also effectively prevent the inclination and tilting of the nut when it enters the product, and can also achieve the purpose of improving production efficiency, reducing production costs, improving the pass rate, and increasing the economic benefits of the enterprise. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com