Gypsum block unresisted-jacking and forming machine

A gypsum block, non-resistance technology, applied in the direction of ceramic molding machine, ceramic molding core, ceramic molding mandrel, etc., can solve the problems of inconvenient installation and transportation, waste of resources, vertical height, large overall quality, etc., and achieve good energy saving , the effect of reducing contact friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

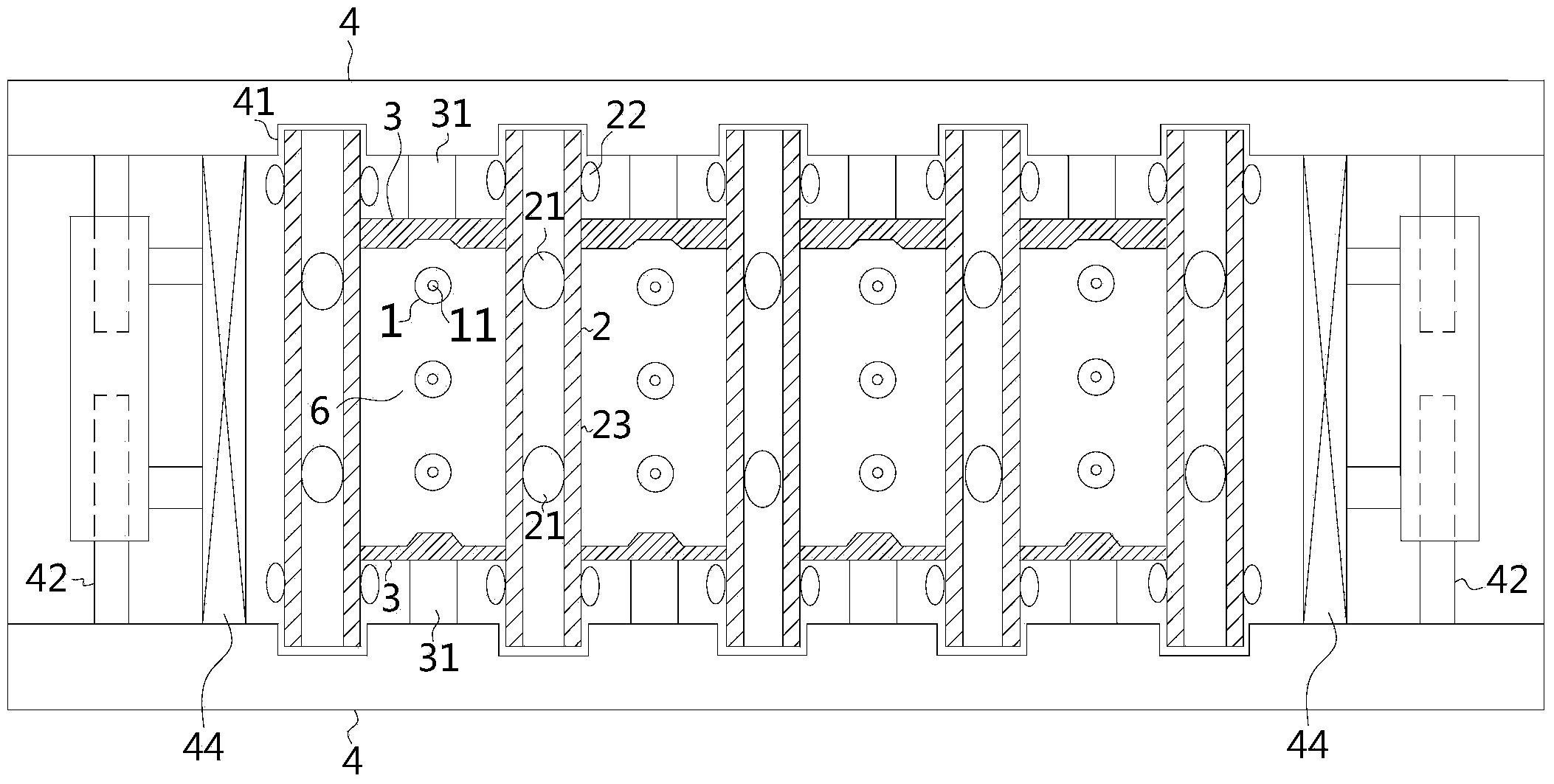

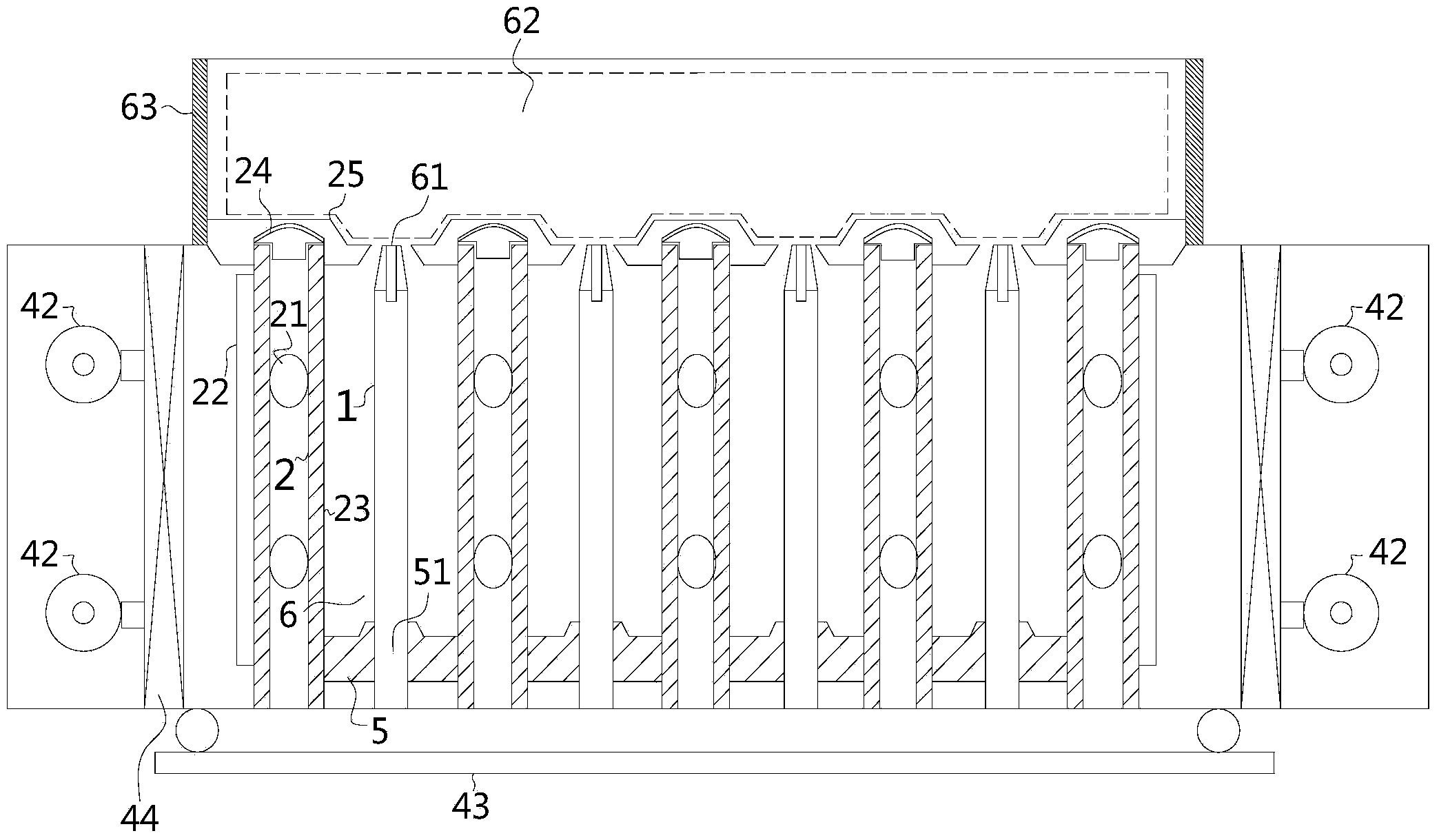

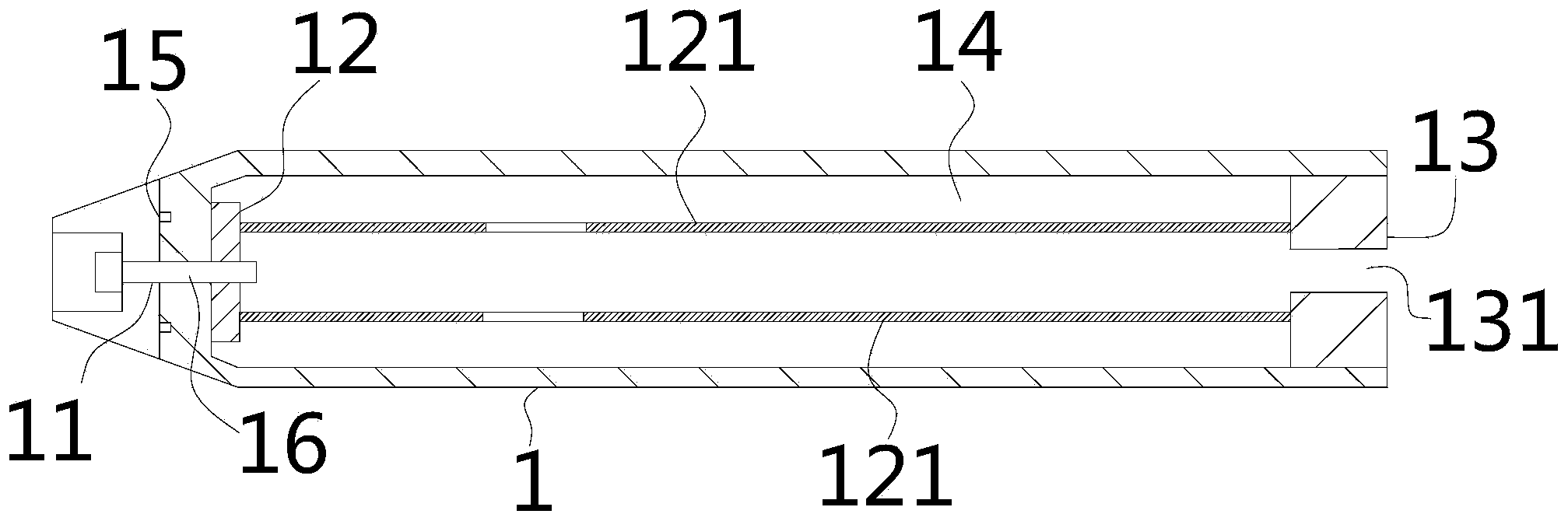

[0022] The present invention will be further described below in conjunction with the drawings.

[0023] Such as figure 1 , figure 2 , image 3 with Figure 4 The shown non-resistance jacking gypsum block forming machine includes a bottom formwork 5, a mandrel passing through the bottom formwork 5 through a bottom formwork hole 51 on the bottom formwork 5, and a pair of support frames for supporting gypsum blocks. 4. Double-layer partition 2. A peripheral baffle 3 arranged on the support frame 4. The double-layer partition 2 is composed of two opposite partitions 23, an inner airbag 21 and an outer airbag 22, and the inner airbag 21 It is arranged between two partitions 23, the outer airbag 22 is arranged on the outer surface of the partition 23, the peripheral baffle 3, the double-layer partition 2 and the bottom template 5 surround the molding cavity 6, and the mandrel 51 is located In the cavity 6, the sides of the bottom template 5 are close to the surface of the peripheral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com