Chlorine ventilation device

A chlorine gas and special technology, which is applied in the direction of titanium halide, etc., can solve problems such as the furnace cannot be produced normally, the furnace leaks molten salt, and the pipe is blocked, so as to achieve the effect of novel concept, avoiding leakage and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

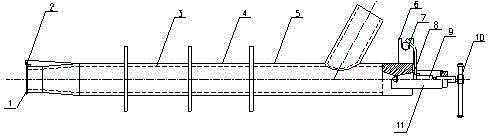

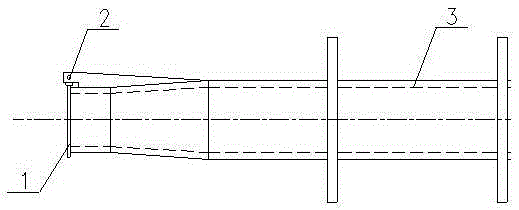

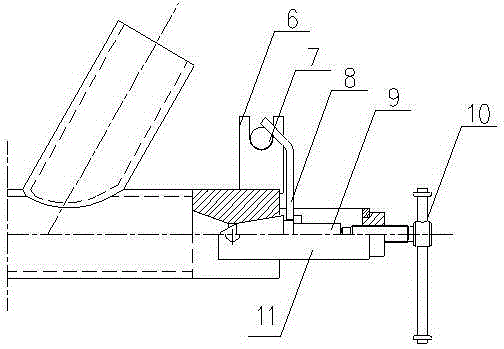

[0013] Embodiment of the present invention: the opening and closing plate 1 is connected to the end of the casting special steel part 3, the supporting steel plate 6 is welded to the tail end of the casting special steel part 3 and the pin 7 is inserted, and the plug 9 is put into the casting special steel part 3 In the reserved hole at the tail, the tail of the plug head 9 is pressed by the steel plate 8, the tightening device 10 is fixed by the bracket 11, the front end shaft of the tightening device 10 withstands the tail of the plug head 9, the anti-oxidation coating 4 and the high temperature and corrosion resistant coating 5 Apply to the surface of each part in turn.

[0014] The opening and closing plate 1 is connected with the end of the casting special steel part 3 through the pin shaft 2 .

[0015] The casting special steel part 3 is an integral pouring structure.

[0016] The position of the plug head 9 in the reserved hole at the end of the cast special steel part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com