Method for making glass substrate of touch control display equipment

A technology of glass substrate and touch display, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., and can solve problems such as slowing down the production speed and disintegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to fully understand the purpose, features and effects of the present invention, now through the following specific embodiments, and in conjunction with the accompanying drawings, the present invention is described in detail, as follows:

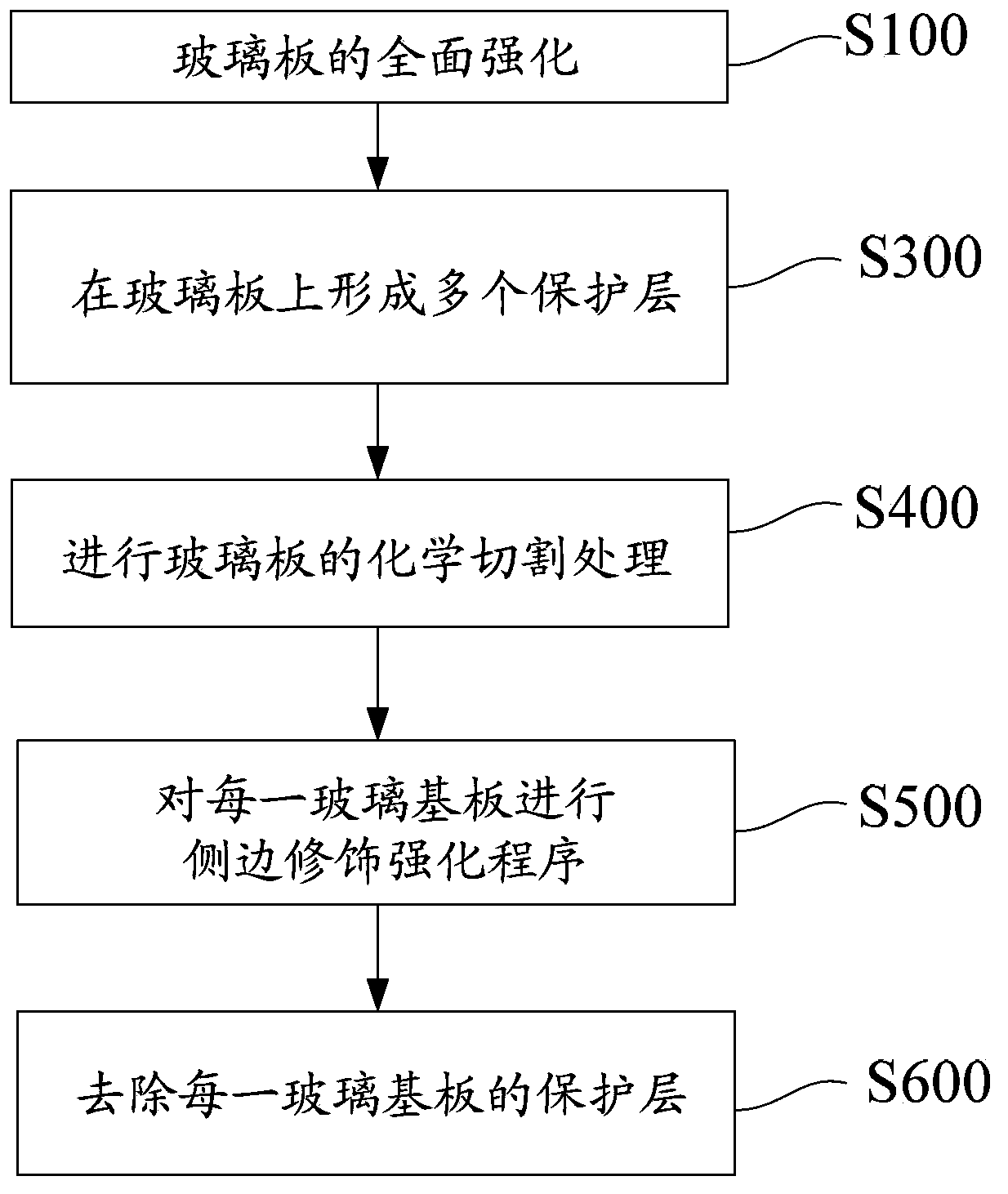

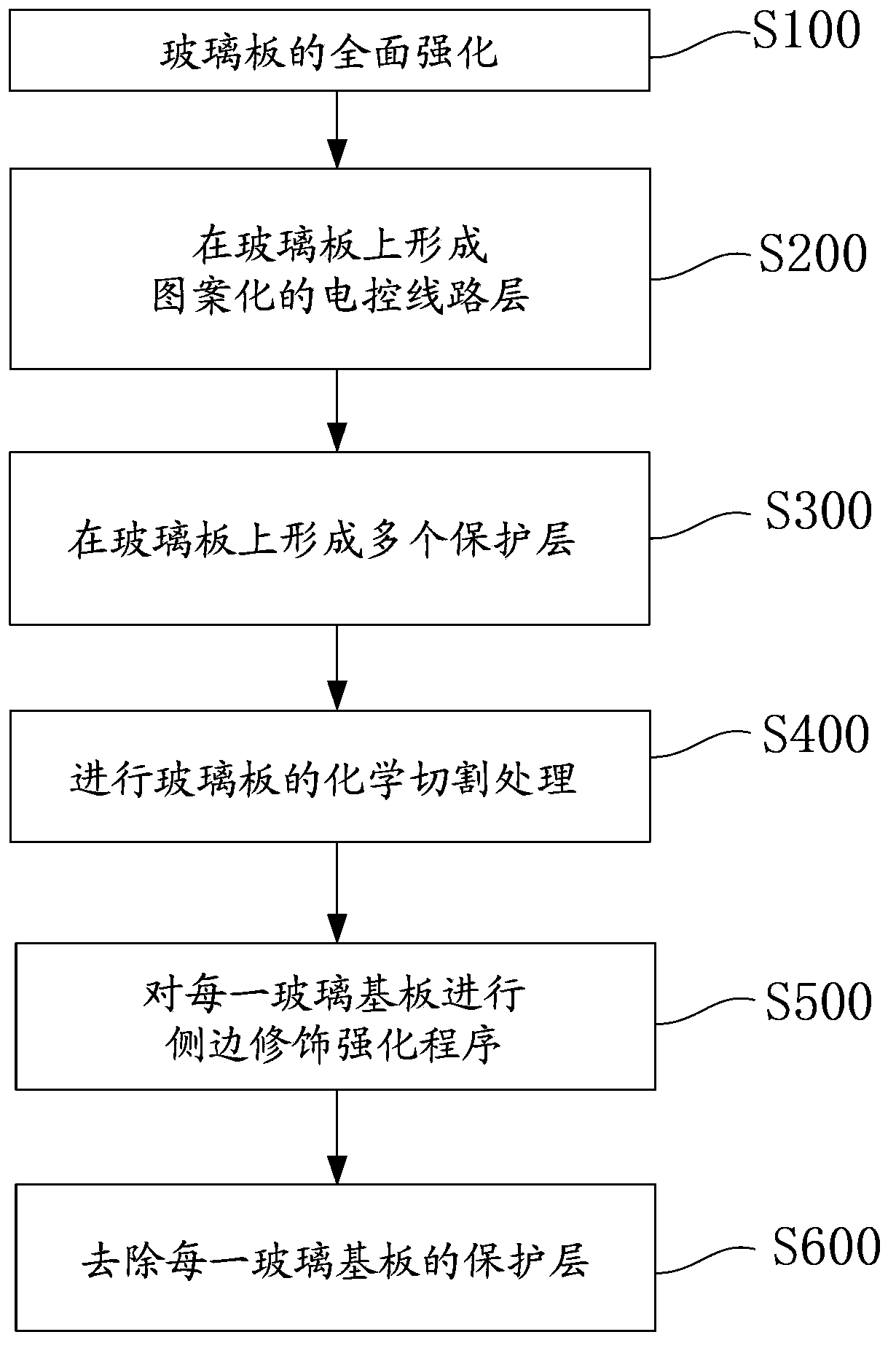

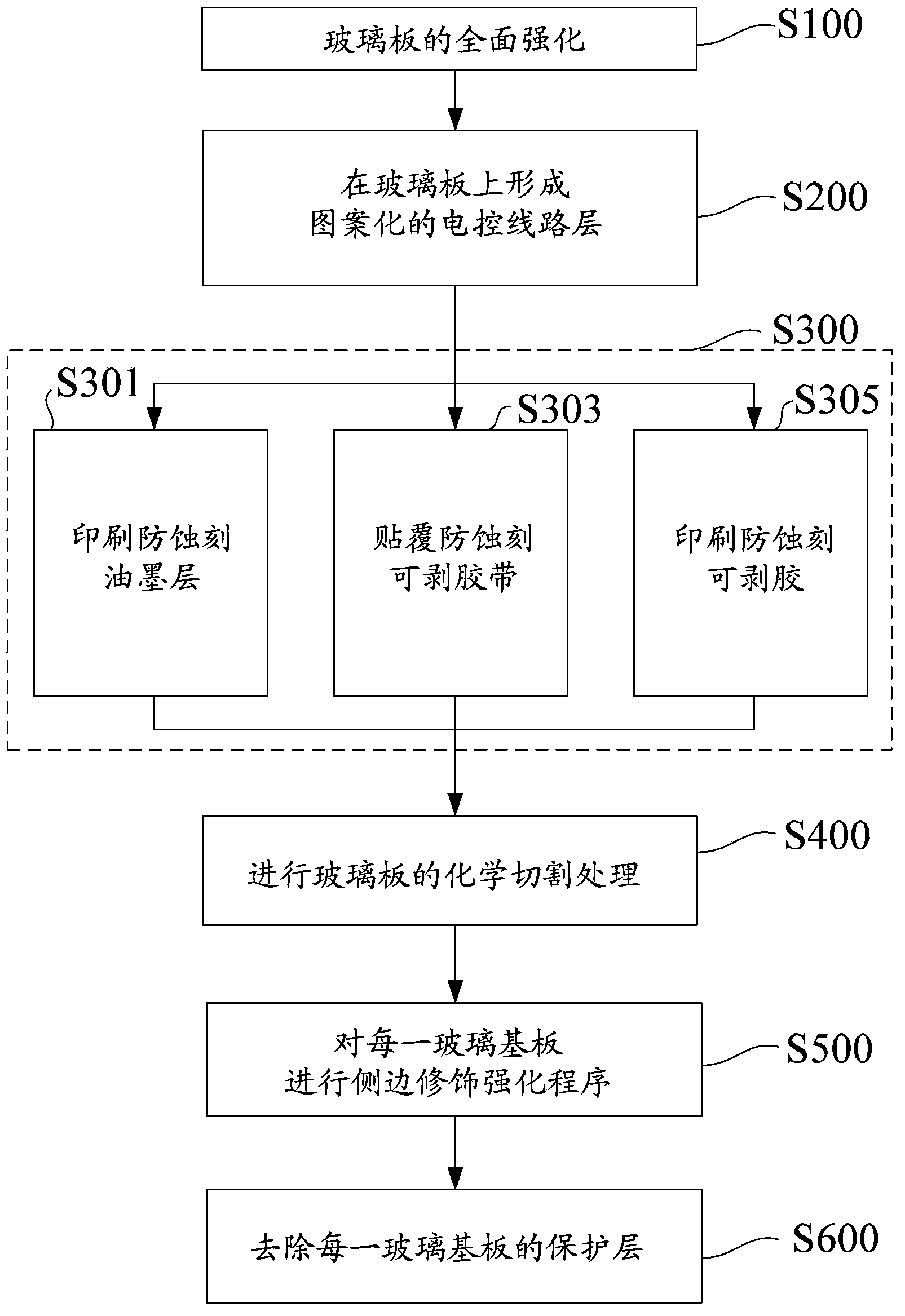

[0032] See first figure 1 , is a flow chart of a method for manufacturing a glass substrate in an embodiment of the present invention, which is applied to manufacturing a glass plate into a plurality of glass substrates.

[0033] Firstly, step S100: performing comprehensive strengthening treatment on the glass plate. There are mainly two types of strengthening treatment, one is thermal strengthening, and the other is chemical ion strengthening. For example, in a chemical ion strengthening process, the glass plate to be strengthened, for example, can be placed in a molten potassium salt, so that the potassium ions can ion-exchange with the sodium ions on the surface of the glass, so that the surface of the glass plate forms a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com