Spheroidizing annealing furnace

A spheroidizing annealing furnace and furnace technology are applied in the field of improvement and invention of spheroidizing annealing furnaces to achieve the effects of low decarburization rate, sufficient protective atmosphere and high spheroidization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

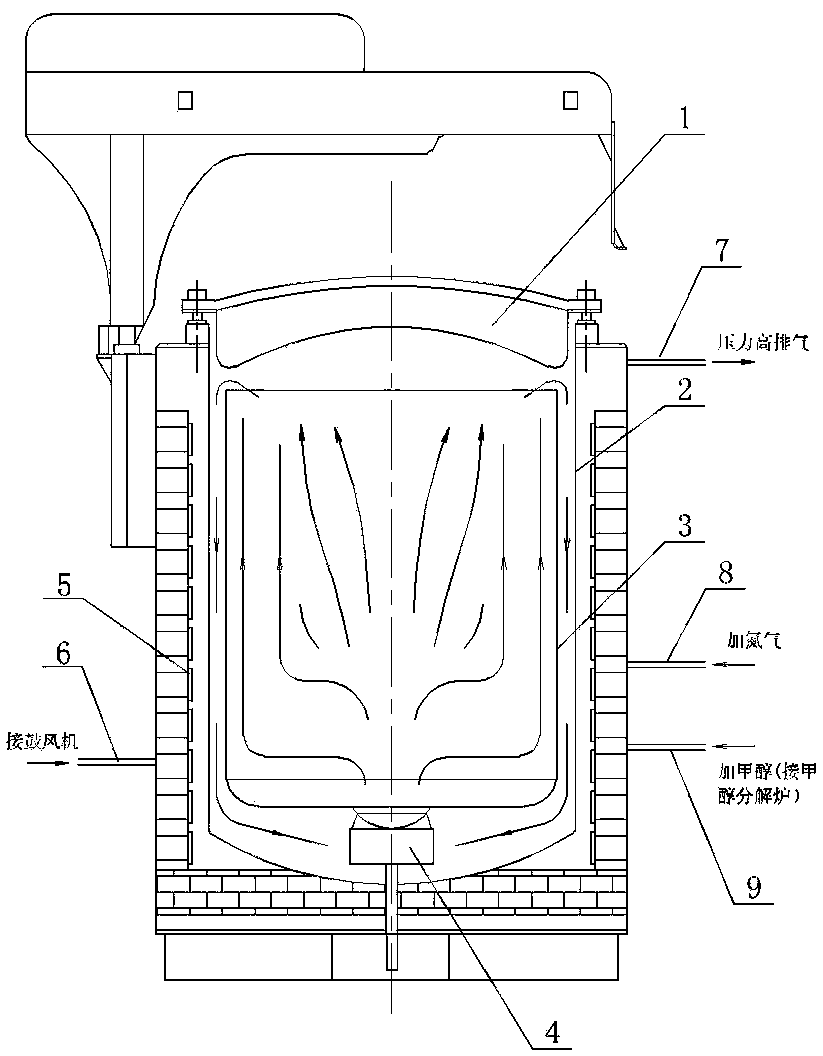

[0010] figure 1 As shown, the spheroidizing annealing furnace of the present invention includes an outer furnace 2, an inner furnace 3, a furnace cover 1 and a centrifugal fan 4, the inner furnace 3 is arranged in the outer furnace 2, and the furnace cover 1 and the inner furnace 3 are facing each other. The bottom of the furnace cover is spherical arc, and the outer furnace 2 is equipped with an electric heating device 5. The centrifugal fan 4 is installed between the bottom of the inner furnace 3 and the bottom of the outer furnace 2. When the centrifugal fan is working, the inner furnace, A forced convection loop is formed between the gap between the inner furnace roof and the furnace cover, the gap between the inner furnace and the outer furnace wall, and the gap between the inner furnace and the outer furnace bottom. The annealing furnace is provided with nitrogen inlet 8, methanol inlet 9, and blast inlet 6 And the overpressure exhaust port 7, the methanol inlet 9 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com