Fastener and manufacturing method thereof

A technology of fasteners and connecting buckles, which is applied in the direction of connecting components, building structures, and friction-clamped detachable fasteners, etc., and can solve the problems of fastener safety reduction, fastener damage, and non-recoverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and specific features therein can be combined with each other.

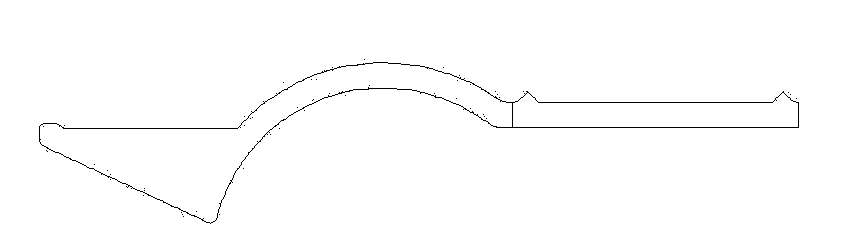

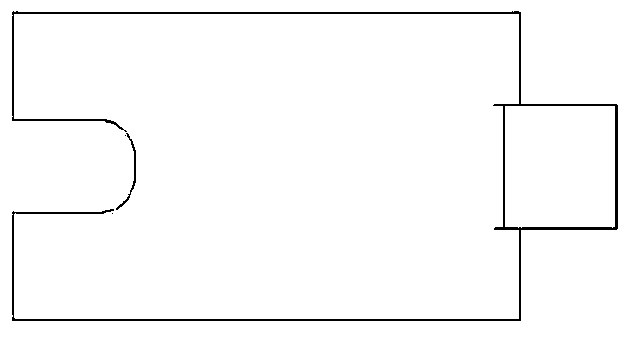

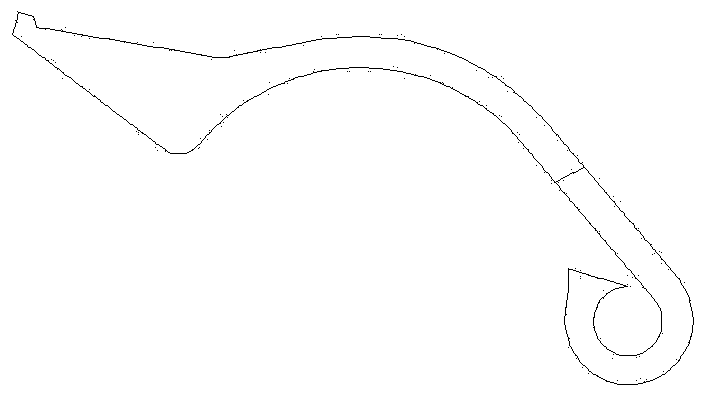

[0099] Refer below Figures 1A-1C A fastener according to a first embodiment of the present invention will be described. Such as Figures 1A-1C As shown, the fastener 104 for clamping an object in this embodiment includes a clamp arm 105 and a clamp arm 106, the first end 107 of the clamp arm 105 is rotatably connected to the first end 108 of the clamp arm 106, and the clamp arm Between 105, 106 is formed a cavity 111 for accommodating the object when it is clamped. The first end 107 of the clamp arm 105 has at least one through hole communicating with the cavity 111, the first end 108 of the clamp arm 106 has at least one extension 110, and the extension 110 is rolled through the through hole toward th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com