Protective door device and sealing strip sawing machine

A technology for protective doors and sawing machines, which is applied to door/window fittings, the arrangement of wing sashes, power control mechanisms, etc., can solve the problems of large areas of protective doors, difficulty in meeting operation needs, affecting operating space, etc., to improve safety. Sex, fast and stable action, easy to use and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

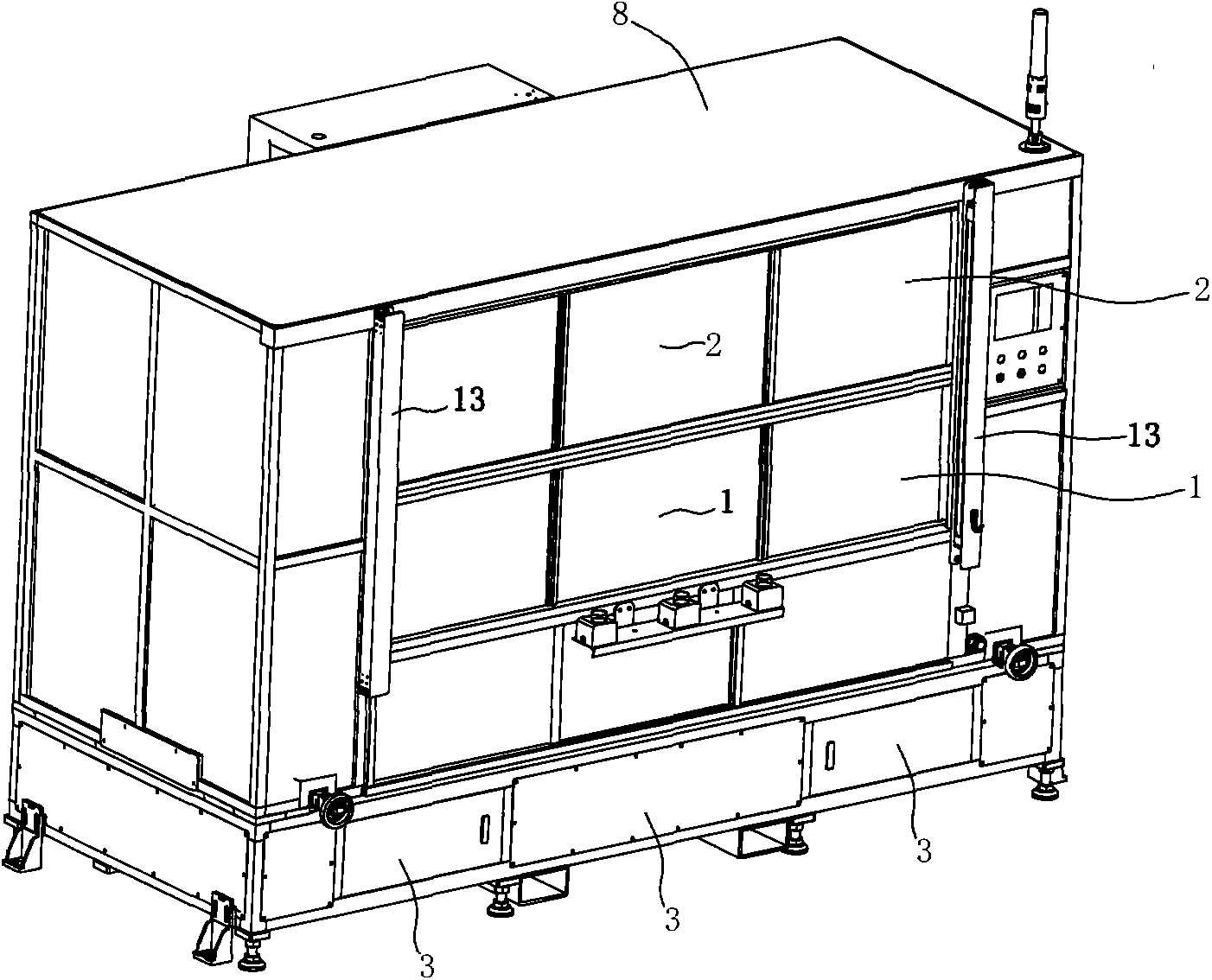

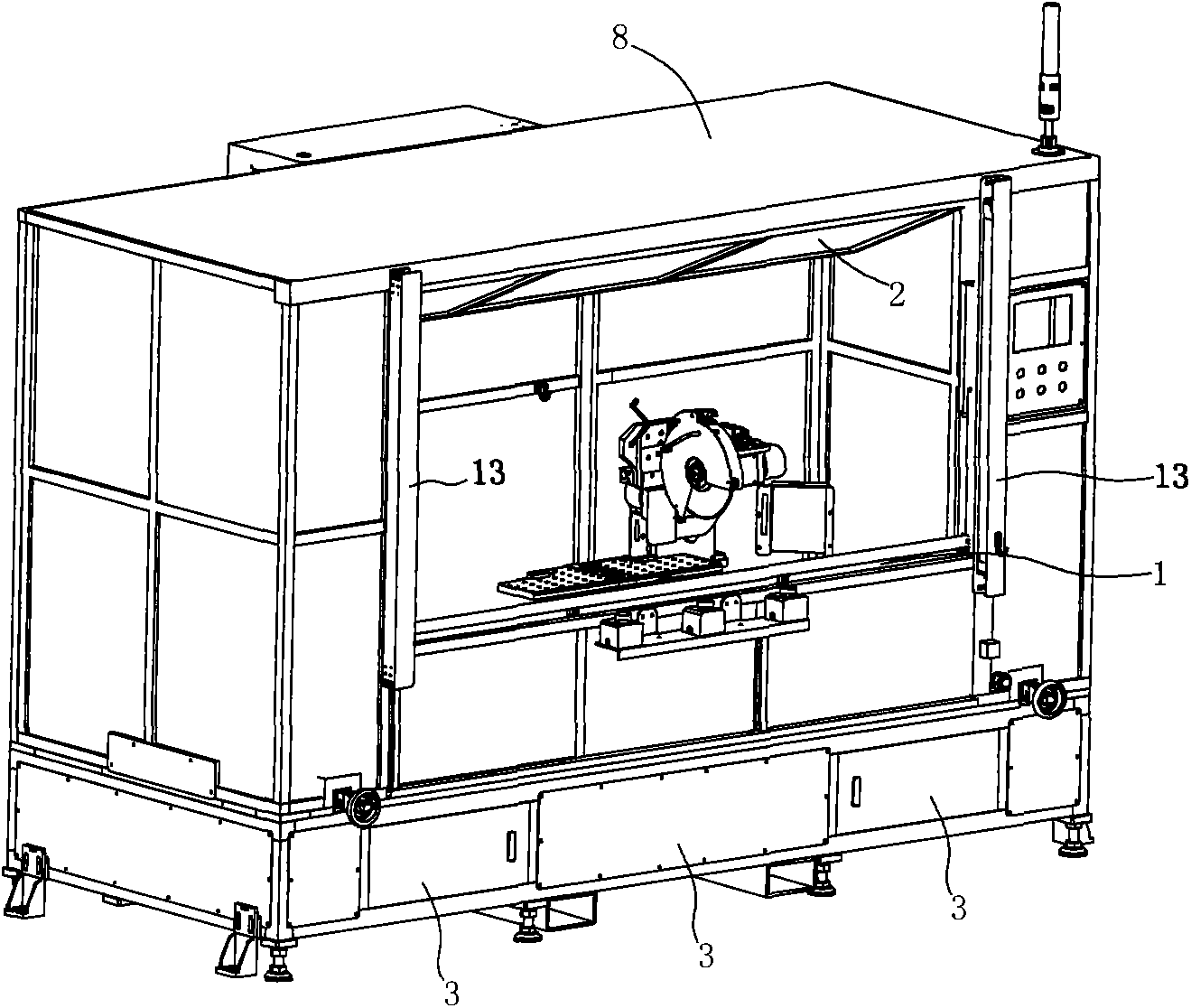

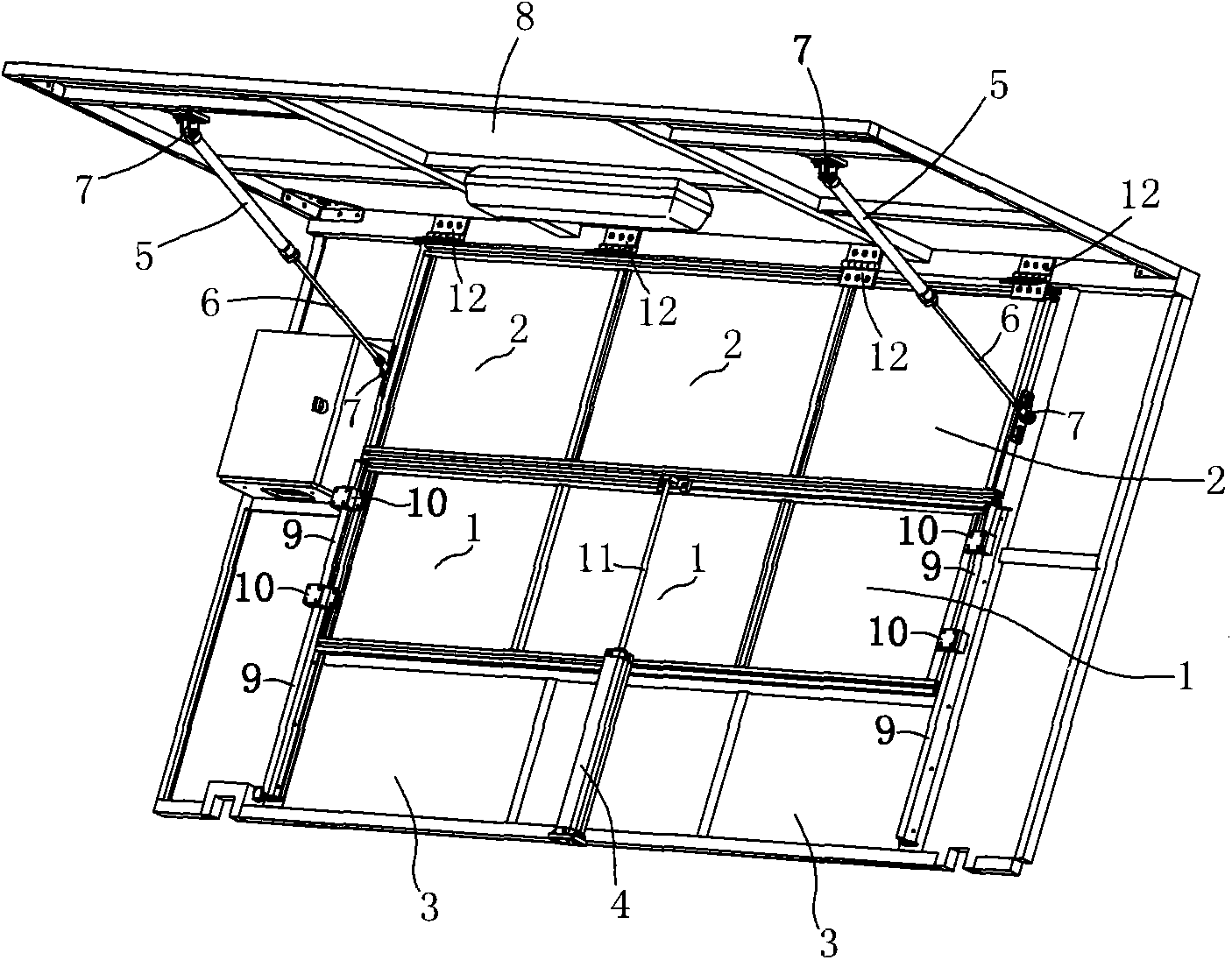

[0030] Such as image 3 , Figure 4 As shown, the sliding door drive cylinder 4 is a single cylinder located in the middle of the sliding door 1, the cylinder is fixed on the machining device frame, and the 11 ends of the piston rod are fixedly connected with the 1 frame of the sliding door. Sliding door 1 two side doorframes are provided with guide rail bar 9 respectively, and every side guide rail bar 9 is provided with a slide block 10 at least, is good with every side setting two slide blocks 10, and slide block 10 is fixedly connected with sliding door 1. The rotary door drive cylinder 5 is arranged as two cylinders, which are symmetrically arranged on the near two sides of the rotary door 2 . Such as image 3 , Figure 4 As shown, among them, image 3 In the closed state of the protective door, Figure 4 It is in the open state of the protective door. in addition, Figure 7 It is a side view of the open state of the protective door of this embodiment.

Embodiment 2

[0032] Such as Figure 5 , Image 6 As shown, the sliding door 1 two side doorframes are provided with guide rail rods 9 respectively, and each side guide rail rod 9 is provided with at least one slide block 10, preferably two slide blocks 10 are set on each side, and the slide block 10 is fixedly connected with the sliding door 1. Sliding door drive cylinder 4 is 2, is arranged on sliding door 1 two side door frames tops respectively, and its piston rod 11 lower ends are fixedly connected with slide block 10. The revolving door drive cylinder 5 is a single cylinder, located in the middle of the revolving door 2, suitable for being installed between the middle frame 15 of the revolving door 2 and the middle frame 16 of the ceiling 8. Such as Figure 5 , Image 6 As shown, among them, Figure 5 In the closed state of the protective door, Image 6 It is in the open state of the protective door. in addition, Figure 8 It is a side view of the open state of the protective d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com