A telescopic and rotatable metal pipe joint

A technology of pipe joints and metal pipes, which is applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve the problems of low working efficiency, high economic cost, and high time cost of test pumps, and achieve simple structure and easy operation. Reliable, low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

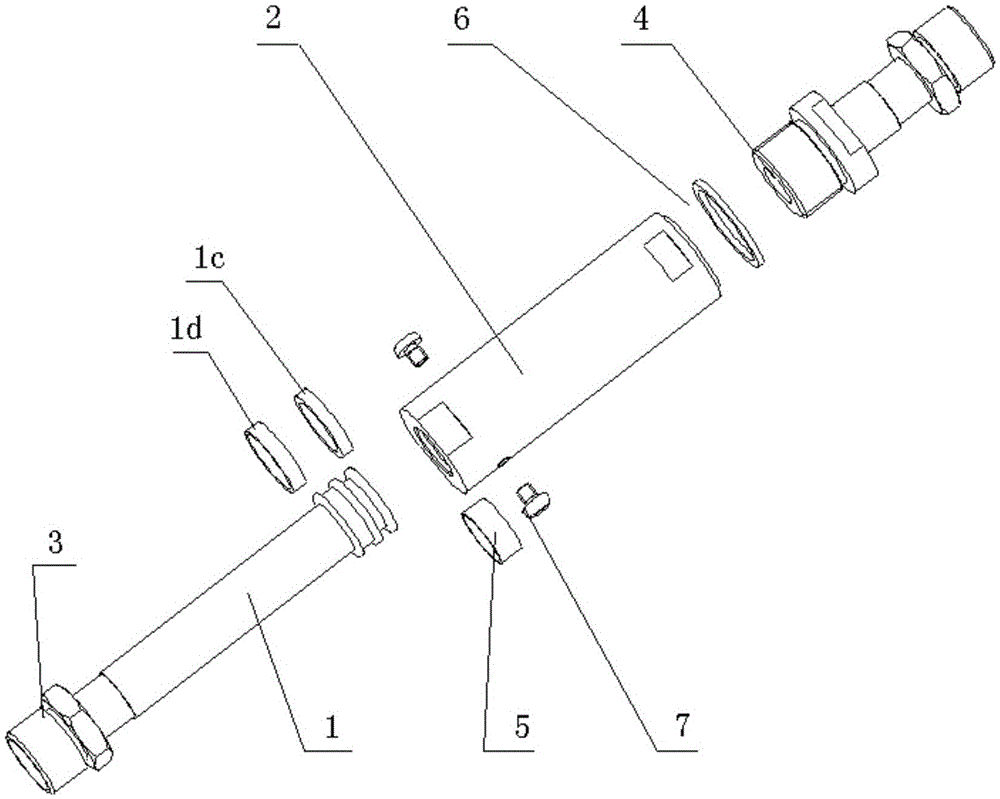

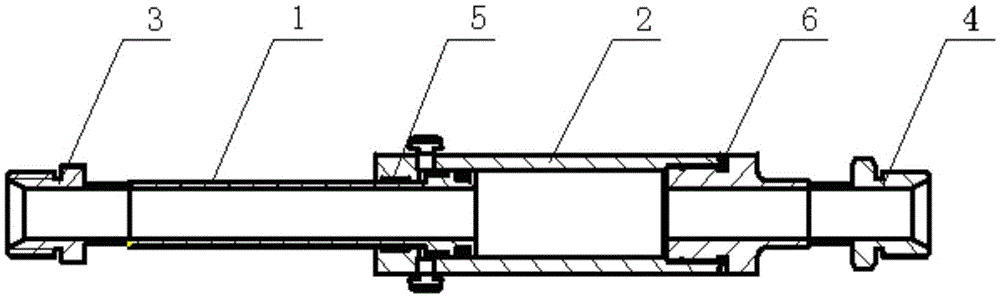

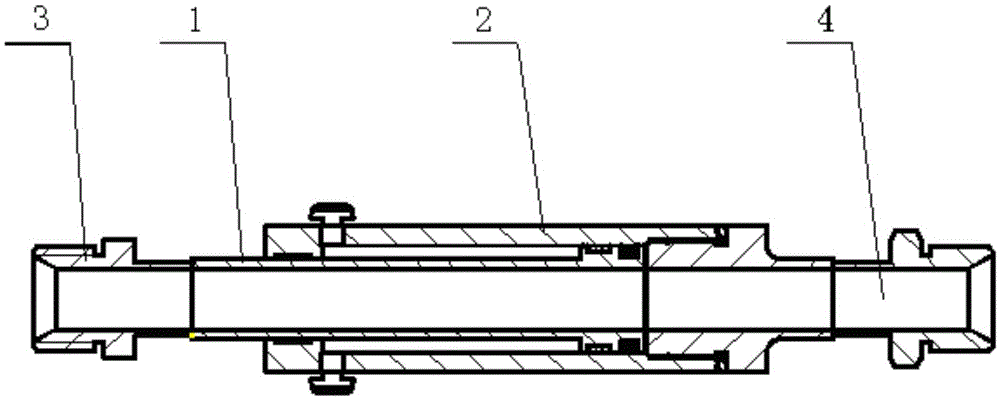

[0029] like figure 1 , figure 2 , image 3 , Image 6 As shown, a retractable and rotatable metal pipe joint of the present invention includes a pipe joint assembly 4 and a connecting pipe assembly that can be assembled together. The connecting pipe assembly includes a piston assembly 1 and a cylinder 2 matched with it, one end of the cylinder 2 is slidingly and sealingly matched with the piston assembly 1, and the other end of the cylinder 2 is connected with the pipe joint assembly 4; the piston assembly 1 includes a hollow tubular One end of the piston rod 1a is a piston head 1b with a central through hole placed in the cylinder 2, and the other end of the piston rod 1a is connected with the pipe joint 3 outside the cylinder 2. The diameter of the piston rod 1a is 14mm, the outer diameter is 18.3mm, the diameter of the central through hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com