Optimal control method for 300MW unit to effectively stabilize temperature of main steam

A technology for optimal control of main steam temperature, applied in adaptive control, general control system, control/regulation system, etc., can solve problems such as easy overshoot and integral saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings,

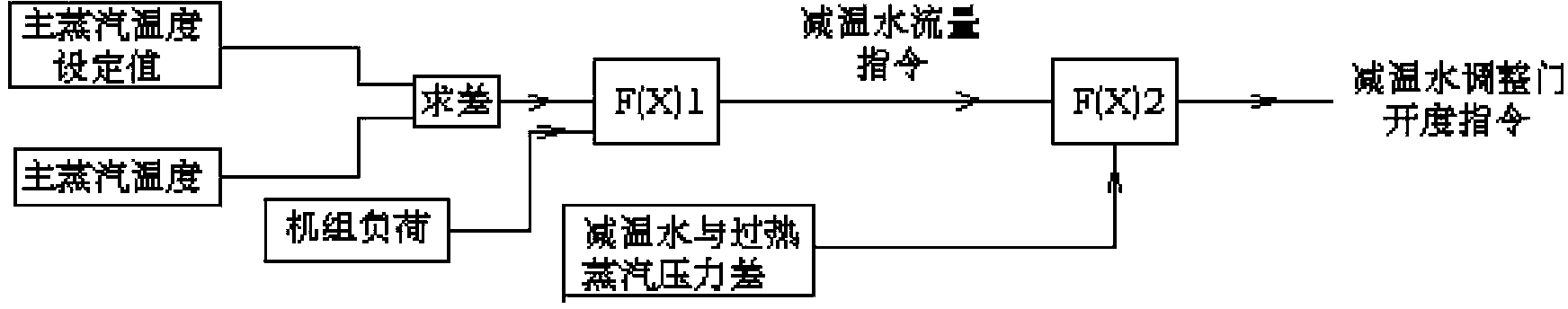

[0048] An automatic control method for effectively stabilizing the main steam temperature of a 300MW unit, such as figure 1 shown, including the following steps:

[0049] ⑴ Calculate the difference between the main steam temperature and the set value of the main steam temperature to obtain the difference A: T1-T2=A,

[0050] Among them, T1 is the main steam temperature, and T2 is the main steam temperature setting value;

[0051] (2) Establish the functional relationship B=F(A) between the difference A and the desuperheating water flow B. The method of determining this functional relationship is to record the cumulative amount of desuperheating water flow required by the 300MW unit under a certain load and the transition time get;

[0052] ①For the test of 300MW unit, under the condition of 50% load, that is, FH=150MW, the difference A is from 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com