Touch screen structure with 3D screen printing effect and light guide effect

A light effect and touch screen technology, applied in the input/output process of data processing, instruments, calculations, etc., can solve the problems of low screen printing yield and difficulty in forming 3D brushed decorative masks, and achieve high screen printing yield and flexible appearance design High performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

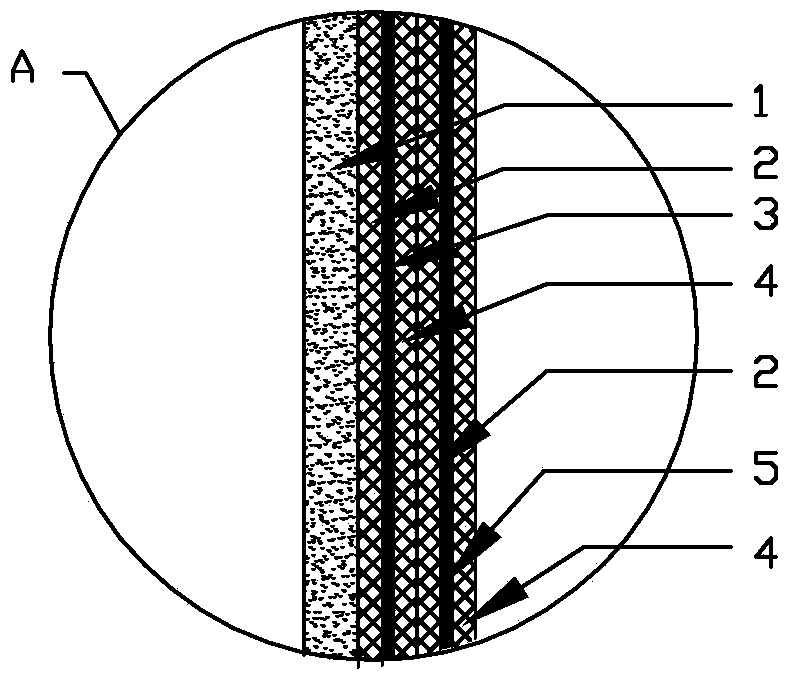

[0025] This embodiment takes the touch screen of FF (PET+ITO Film) structure as an example, as Figure 1 to Figure 4 The shown touch screen structure with 3D silk screen effect and light guide effect includes a protective layer 1, a polyester film layer 4, and an ITO conductive film in sequence.

[0026] A 3D brushed decorative film layer 3 is arranged on the non-display area on the non-conductive surface of the polyester film layer 4; a decorative film with a 3D brushed effect is formed by dot silk screen printing, which can realize a variety of colors and an aesthetic appearance of the touch panel .

[0027] On the position of the button 9 on the non-conductive surface of the polyester film layer 4, a light-transmitting ink layer 6 is arranged, and an ink with a certain light-transmitting requirement is formed by silk screen printing. On the ester film layer 4, the process yield is relatively high.

[0028] A light-guiding ink layer 7 is arranged on the position of the but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com