Fault structure three-dimensional modeling method

A 3D modeling and fault technology, applied in 3D modeling, image data processing, instruments, etc., can solve the problems of faults and stratum grid spaces not being closely matched, gaps or overlapping, etc., to improve accuracy and reliability, The effect of guaranteeing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

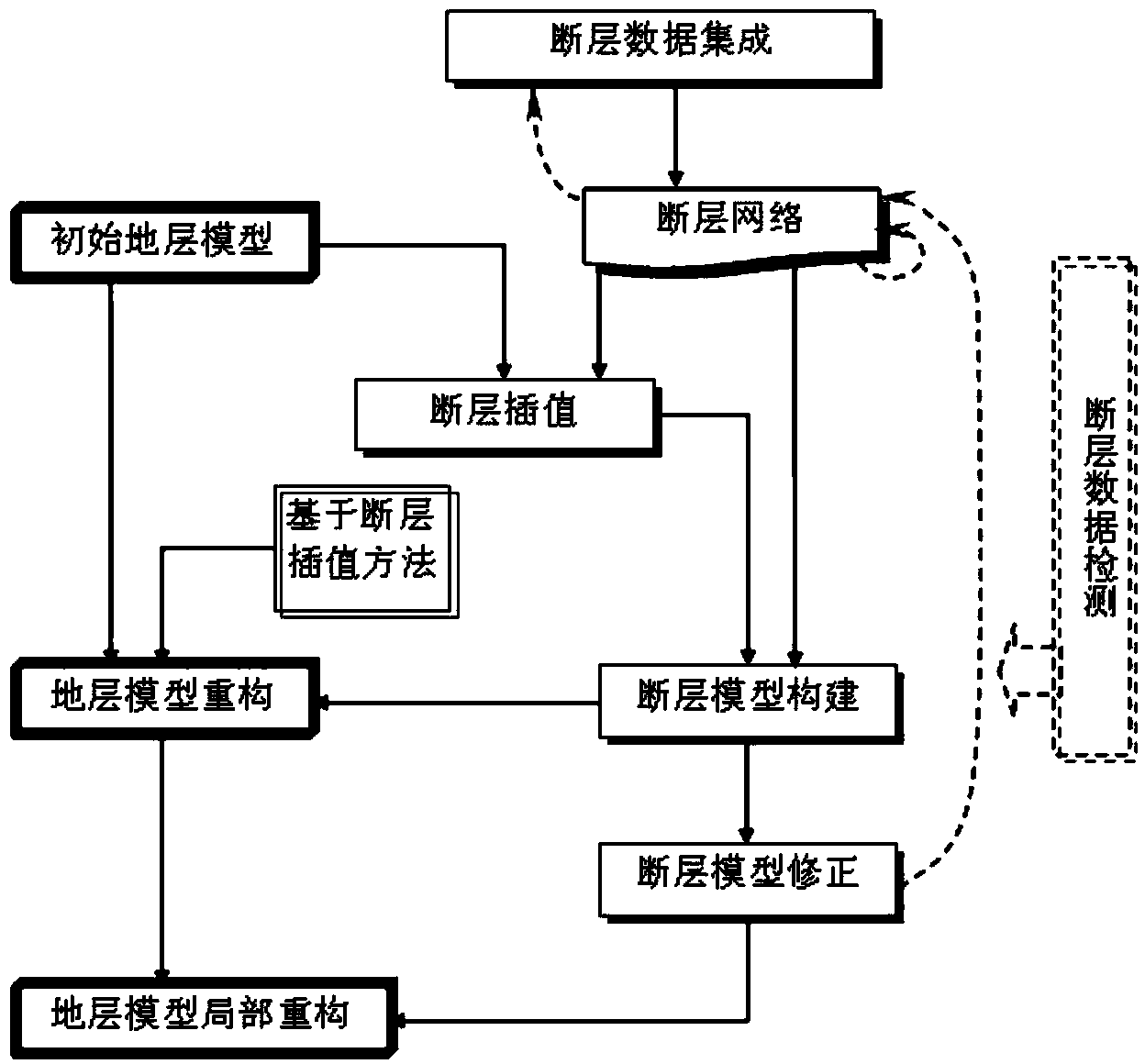

[0123] The application of the 3D modeling method for the fault structure of a gold mine, the specific implementation framework is as follows Figure 8 Shown:

[0124] Collect, process and store fault data in mining areas through fault data acquisition equipment. Fault data acquisition equipment includes traditional survey, electronic survey, geological drilling, seismic detection, geological radar, total station, GPS survey and digital scanner. Use Oracle database, GIS and other tools to digitize the original data, and store, manage, maintain and process information.

[0125] The structural form of the mine is dominated by faults, these faults are tension-torsion or compression-torsion faults, with a dip angle of 35° to 80°, a dip of 180° to 220°, and a drop of 3 to 30 meters (Table 5). Integrate boreholes, 2D / 3D profiles, structural geological maps, and fault attributes into the system, extract fault control points from them, and interpret them to form Class I and Class II ...

specific Embodiment 2

[0130] Application of 3D modeling method of fault structure in a coal mine.

[0131] Step 101: Collect, process and store fault data in the mining area through fault data acquisition equipment.

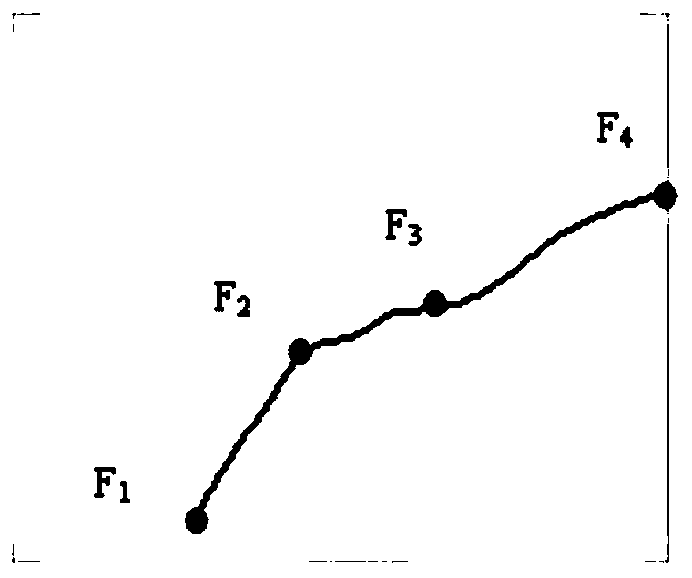

[0132] Step 102: This area is an area with extremely active tectonic activities, and the geological structure is mainly based on faults. Faults are relatively developed in the mining area, and more than 40 large and small faults have been exposed. The northwest wing of the syncline mostly develops strike compressive reverse faults, while the southeastern wing is dominated by high-angle dipping or oblique normal faults of extensional and torsional nature; the fault strikes are divided into two groups: northeast and northwest. Faults with drop greater than 50m are mainly distributed at the southern end of the southeast wing. Integrate borehole (Fig. 9(a)), 2D / 3D profile (Fig. 9(b)), structural geological map (Fig. 9(c)), and fault attributes (Table 6) into the system, and extract faul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com