Substrate processing equipment

A substrate processing device and technology for substrates, which are applied in the directions of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as larger space and reduced processing capacity, and achieve improved processing capacity and small height and size. , the effect of good processing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described with reference to the drawings. The following embodiments are examples of actualizing the present invention, and the embodiments do not limit the technical scope of the present invention.

[0055] In addition, in the following description, the "surface" of a substrate means the surface on which a pattern (for example, a circuit pattern) is formed on the principal surface of the substrate, and the "rear surface" means the surface opposite to the surface. In addition, the "upper surface" of the substrate refers to the surface facing the upper side among the main surfaces of the substrate, and the "lower surface" refers to the surface facing the lower side (regardless of whether the front surface or the back surface is).

[0056]

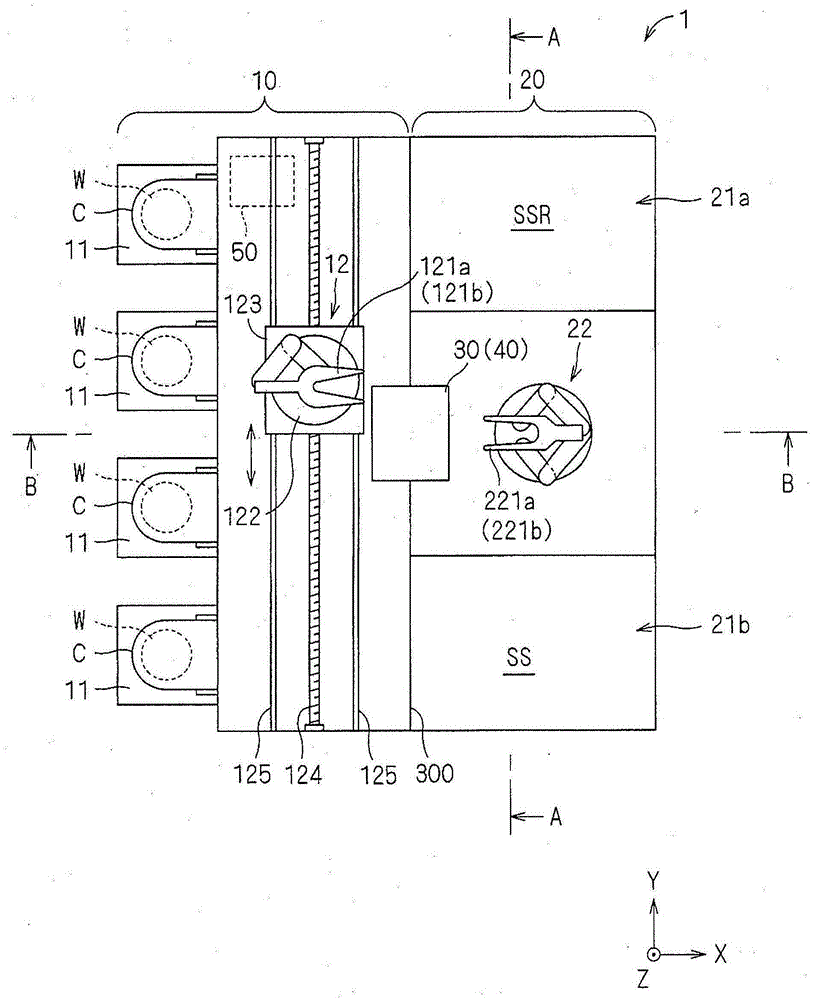

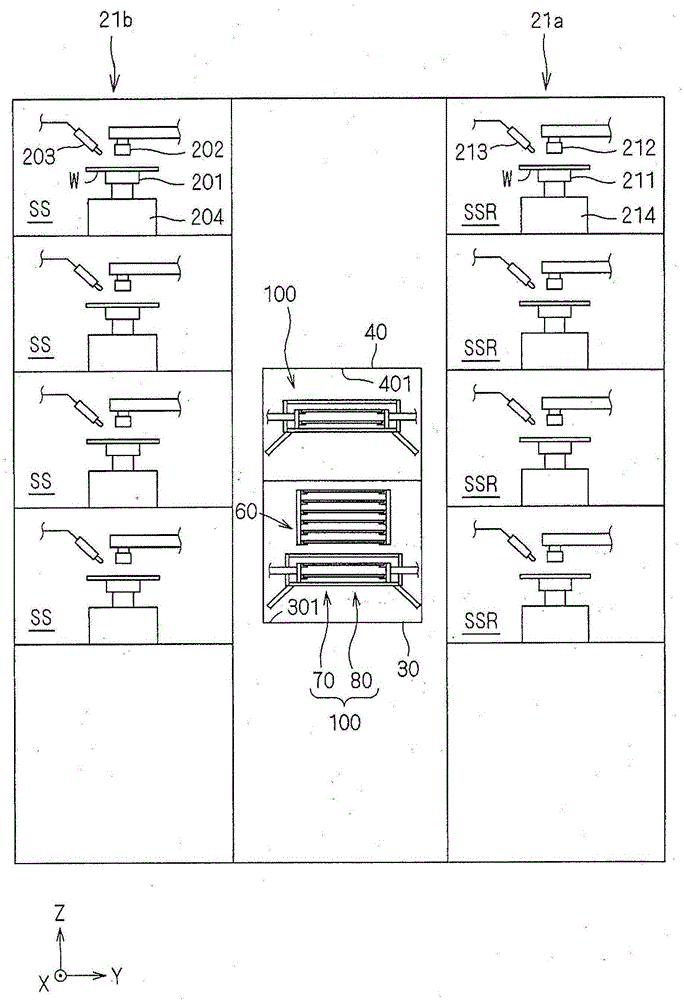

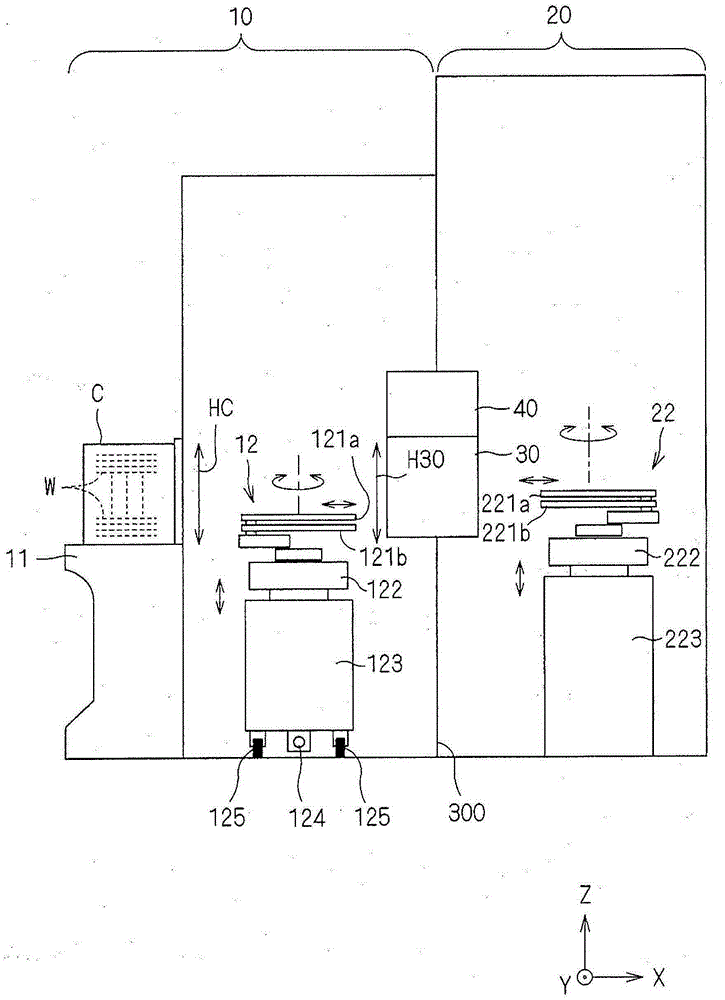

[0057] refer to figure 1 , figure 2 , the configuration of the substrate processing apparatus 1 according to the embodiment will be described. figure 1 It is a plan view o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com