Novel silicon steel sheet slot wedge manufacturing and installation method

A silicon steel sheet and slot wedge technology, which is applied in the field of new silicon steel sheet slot wedge manufacturing and installation, can solve the problems of low motor stator inductance and reduced motor efficiency, and achieve the advantages of reducing heat generation, prolonging service life and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

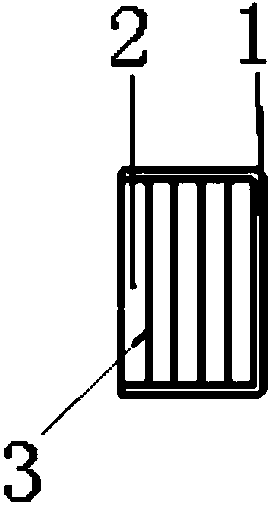

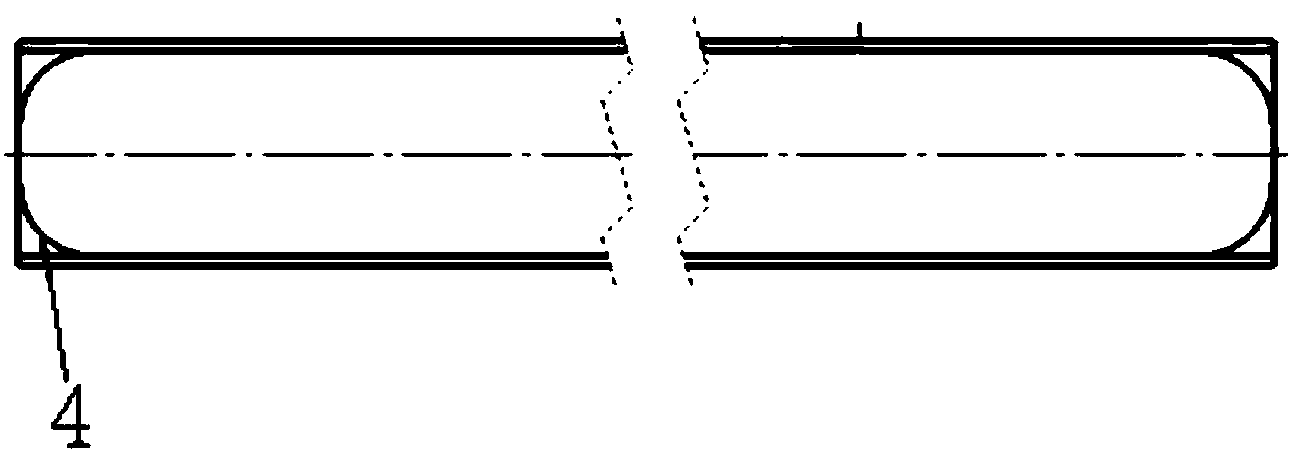

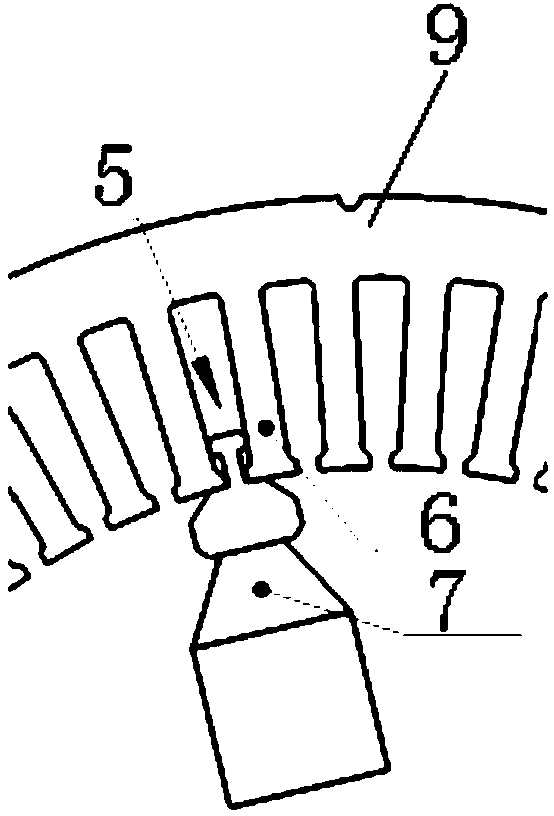

[0024] Such as Figure 1 ~ Figure 4 As shown, a new type of silicon steel slot wedge, including silicon steel sheet 1, insulating tape 2, high temperature resistant glue coating 3, fillet 4, notch 5, stator core teeth 6, crimping tooling 7, enameled wire 8 , embedded wire stator 9;

[0025] 1) Stack several cold-rolled non-oriented silicon steel sheets 1, coat the middle with high-temperature resistant anaerobic glue, place them under a press with a flat bottom, and press them flat.

[0026] 2) Put the flattened silicon steel sheet 1 stack into the oven until it is dried.

[0027] 3) After the glue is completely dried, wire-cut the laminated silicon steel sheet to cut out a cuboid shape with a suitable size, with rounded corners at both ends of the silicon steel sheet 1 to prevent the slot wedge from being bumped and damaged by the embedded wire stator 9 during insertion. core slot.

[0028] 4) Wrap the three sides of the silicon steel sheet 1 with adhesive insulating tape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com