Spar type floating structure

A technology for structures and floating bodies, which is applied to floating buildings, hulls, hydrodynamic characteristics/hydrostatic characteristics, etc., and can solve problems such as difficult to ensure stability, large up and down swings and pitch swings, which are difficult to overcome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

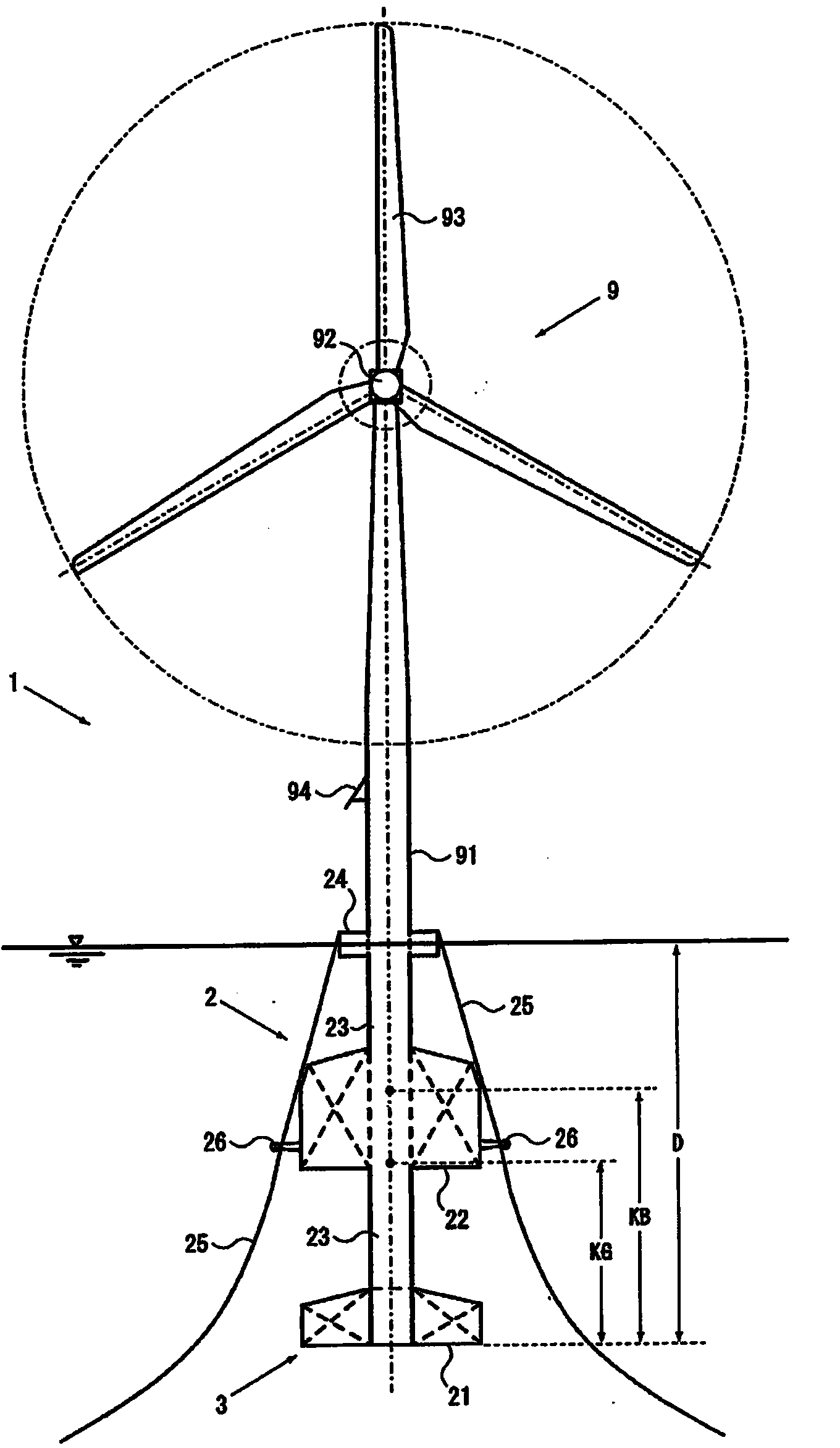

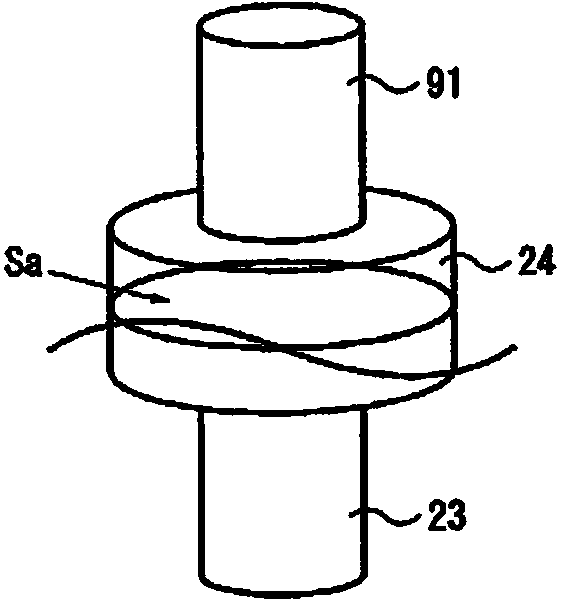

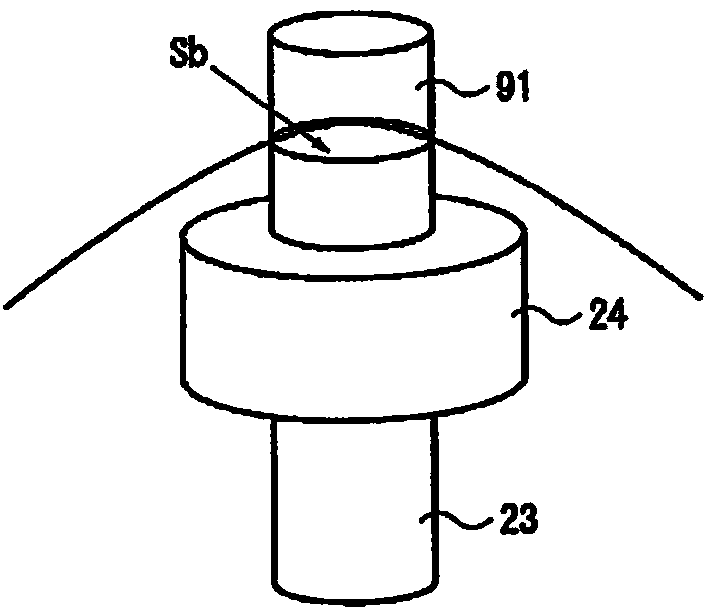

[0041] Next, use figure 1 ~ FIG. 5 demonstrates the columnar floating body structure of embodiment of this invention. here, figure 1 It is an overall configuration diagram of the columnar floating body structure according to the first embodiment of the present invention. Fig. 2 is a diagram for explaining the function of the third expansion part, Figure 2A When representing a normal wave, Figure 2B When high waves are indicated, Figure 2C Represents the wave force characteristic curve. Fig. 3 is a diagram for explaining the function of the second expansion part, Figure 3A Indicates the schematic illustration, Figure 3B Represents the wave force characteristic curve.

[0042] Such as figure 1 As shown, the column-type floating body structure 1 of the first embodiment of the present invention has a floating body part 2 having an elongated shape and a counterweight part 3 disposed on the floating body part 2, and the floating body part 2 is moved by the weight of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com