Exhaust gas purification system for working machine

An exhaust gas purification system and operating machine technology, applied in exhaust gas treatment, electrical control, mechanical equipment, etc., can solve problems such as DPF damage, neglect of the importance of manual regeneration, and rise in filter internal temperature to achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

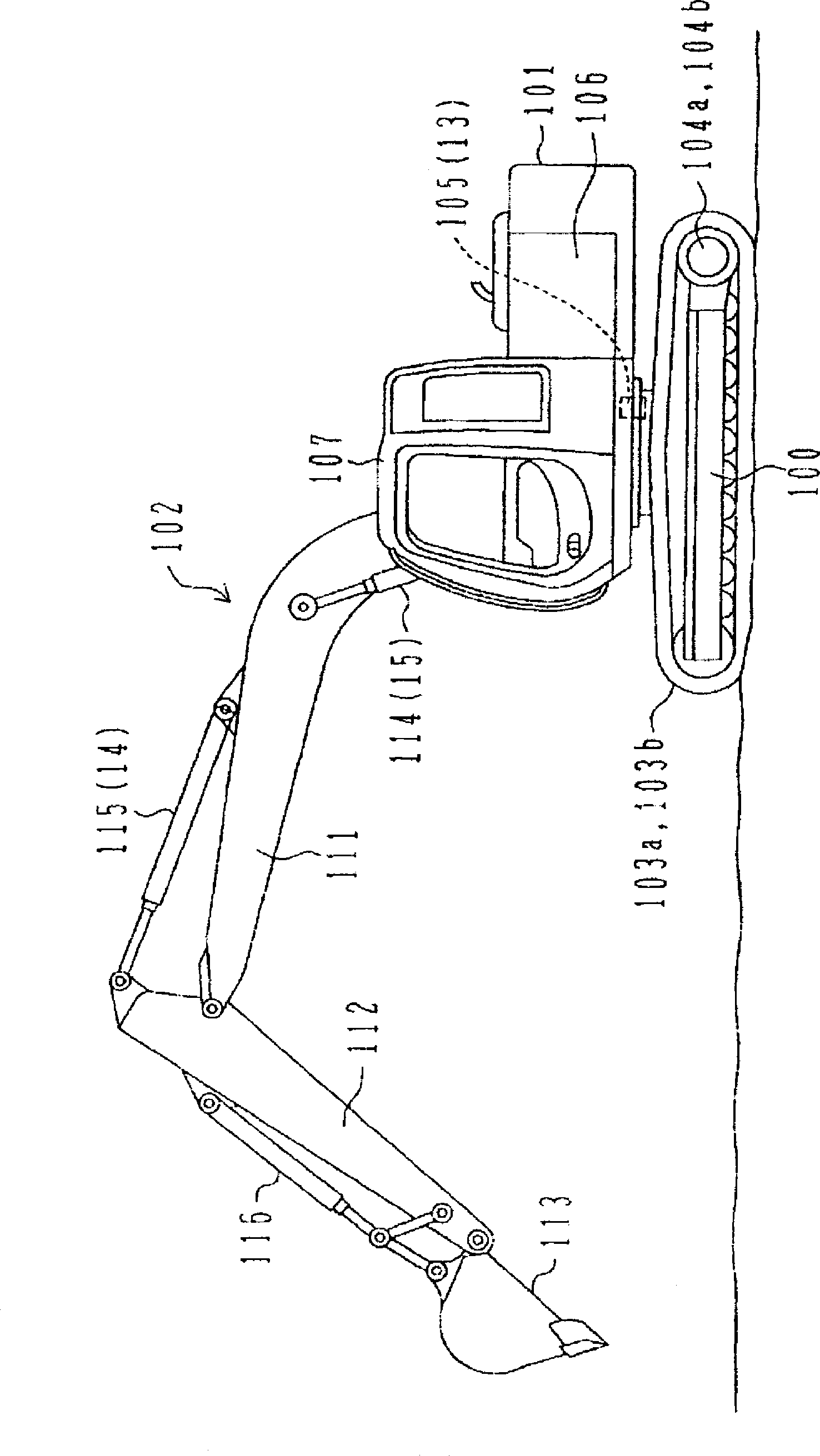

[0033] Hereinafter, a first embodiment of the present invention will be described using the drawings.

[0034] ~Structure~

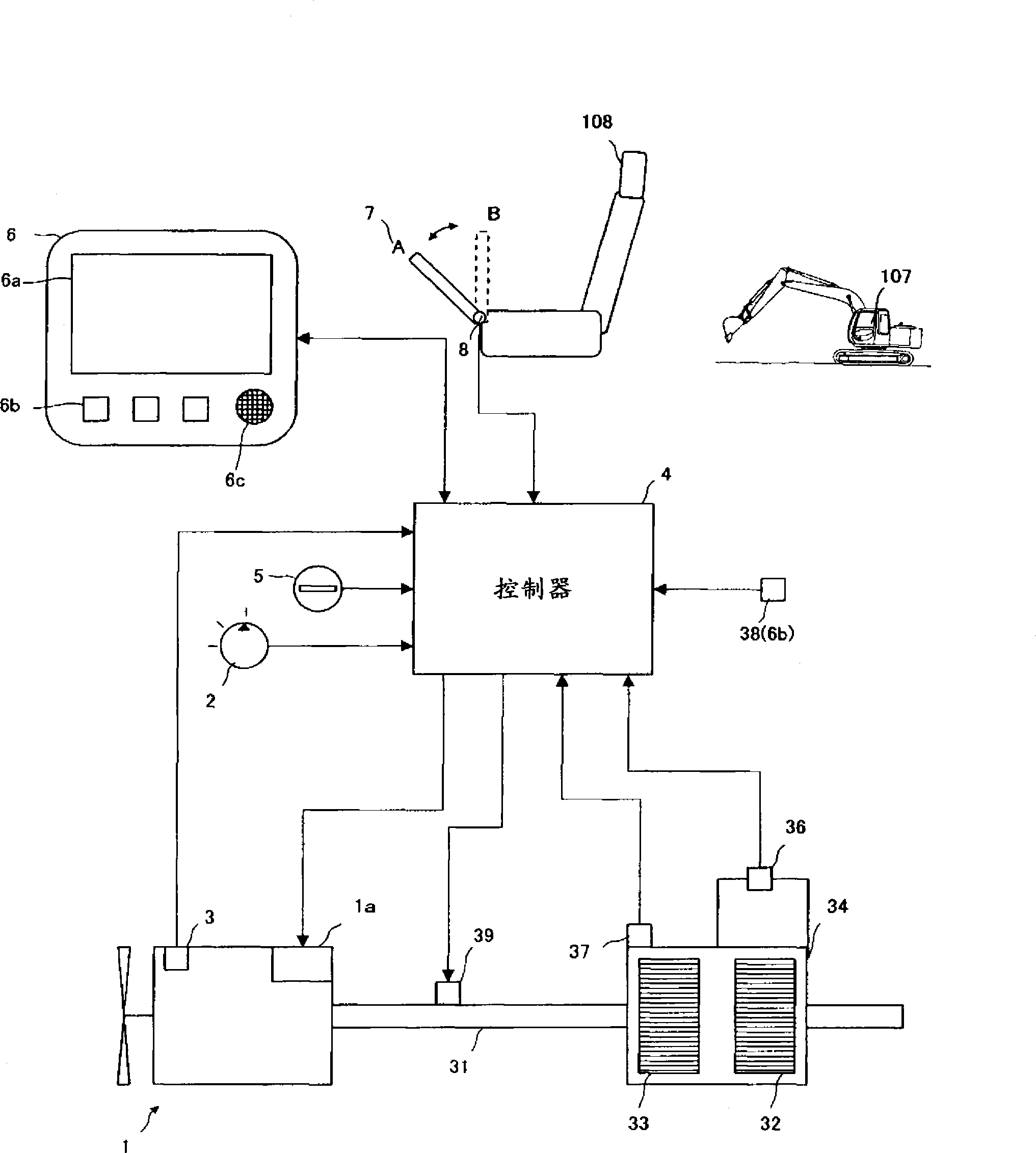

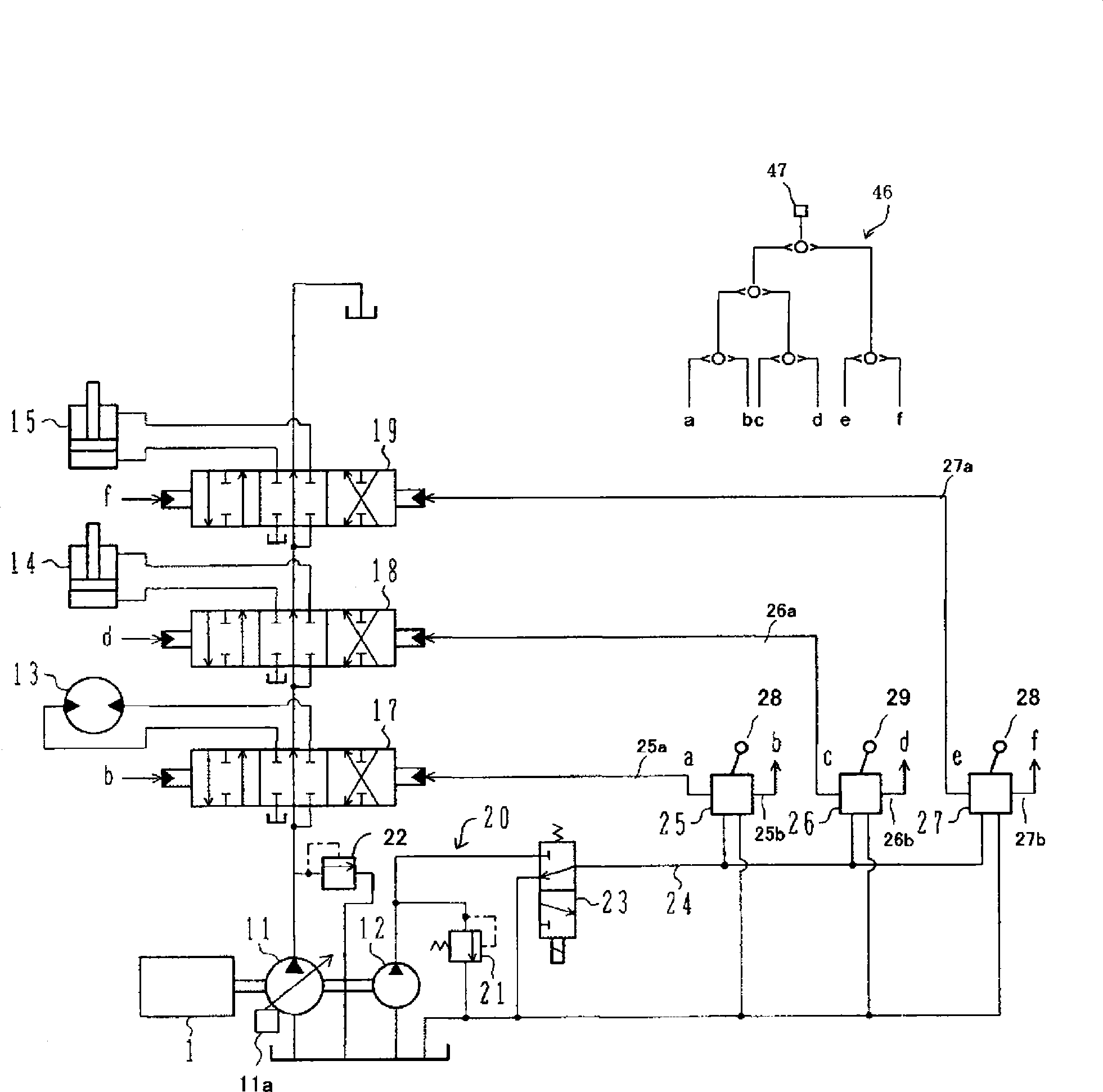

[0035] figure 1It is a figure which shows the whole structure of the exhaust gas purification system of the working machine which concerns on this Embodiment of this invention.

[0036] A work machine (for example, a hydraulic excavator) is equipped with a diesel engine 1 having an electronic governor 1 a as an electronic fuel injection control device. The target rotational speed of the engine 1 is commanded through the engine control dial 2 , and the actual rotational speed of the engine 1 is detected by the rotational speed detection device 3 . The command signal of the engine control dial 2 and the detection signal of the speed detection device 3 are input to the controller 4, and the controller 4 controls the electronic governor 1a according to the command signal (target speed) and the detection signal (actual speed), thereby controlling the engine...

no. 2 Embodiment approach

[0117] ~Technical Issues~

[0118] In the control of the first embodiment, the operation of the exhaust gas purification system when returning from the standby state to the working state will be described. During standby, PM accumulation may worsen than during operation. Therefore, when it is determined that the hydraulic excavator is in the working state and the set times t1, t2, and t3 corresponding to the working state are reset, the set time t1 corresponding to the working state is determined based on the elapsed time measured during standby. , t2, t3, in fact, the change of the warning sound is delayed.

[0119] use Figure 6 Further details. Figure 6 It is a conceptual diagram explaining the outline of technical problems caused by the difference in setting time between the standby state and the working state. The horizontal axis is time, and the vertical axis is accumulation amount. Let the PM accumulation amount for which the warning sound should be changed be the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com