Air energy dryer

An air energy drying and air energy technology, applied in the direction of dryers, drying, drying gas arrangement, etc., can solve the problems of inability to reuse hot and humid air in the drying room, unstable boiler pressure, and dependence on manual operation, etc., to achieve Good constant temperature effect, good dehumidification effect, reduce the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

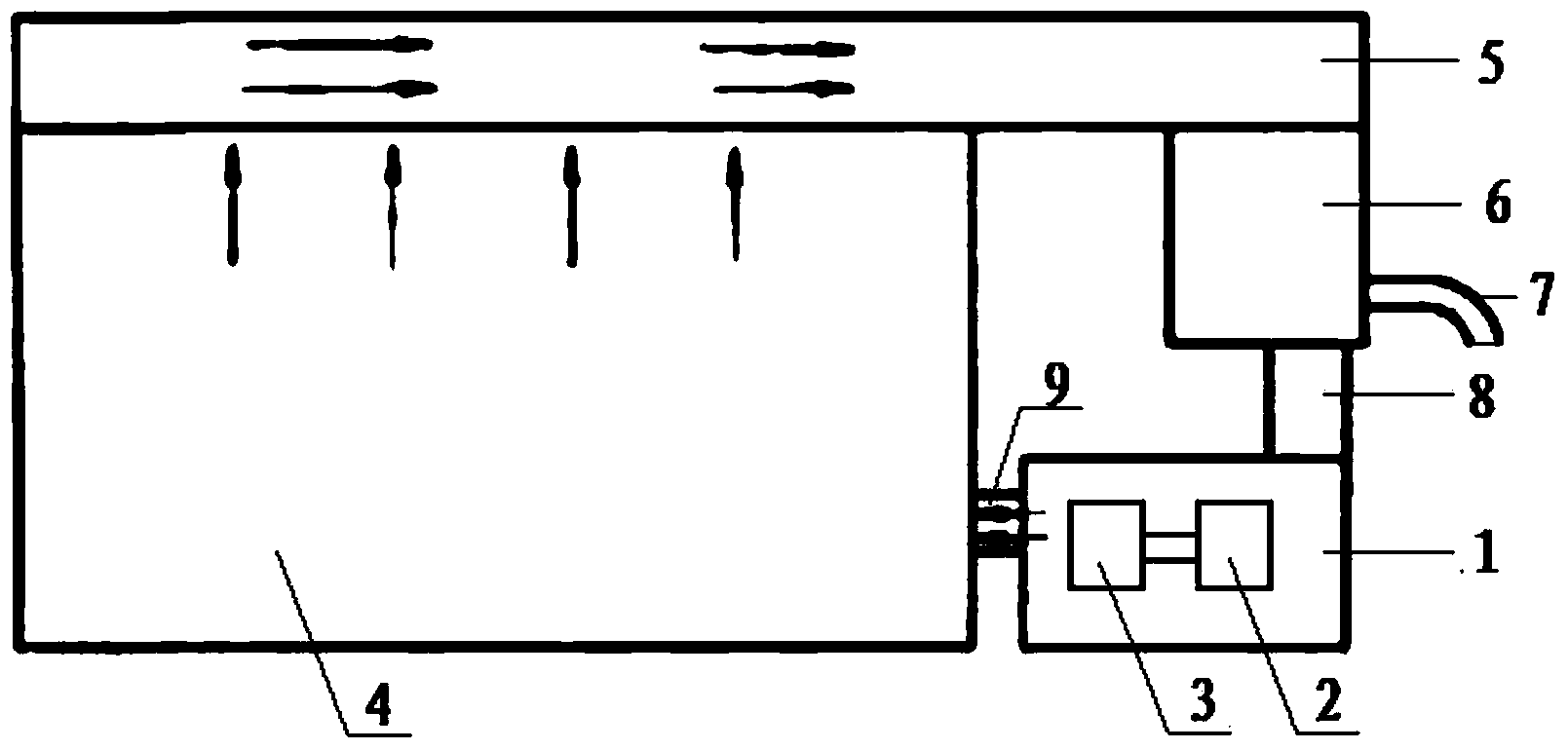

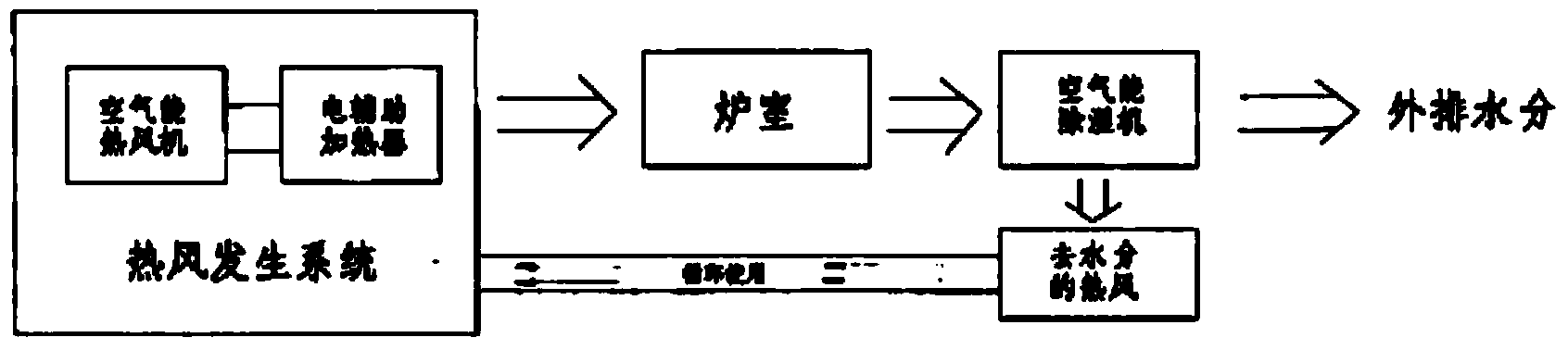

[0016] like figure 1 and figure 2 As shown, an air energy dryer includes a hot air generating system 1, a drying furnace chamber 4 and an air energy dehumidifier 6. The hot air generating system 1 is automatically controlled by a computer, and the generated hot air is transported to the drying machine through a hot air delivery pipe 9. The dry oven chamber 4 performs the drying operation, and the generated water vapor is transported to the air energy dehumidifier 6 through the water vapor pipeline 5. The air energy dehumidifier 6 cools down and discharges the moisture from the drain pipe 7, and the obtained cold air passes through the circulation pipeline 8 Return in the hot air generation system 1.

[0017] The hot wind generating system 1 includes an air-energy hot air blower 2 and an electric auxiliary heater 3. During t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com