Method for manufacturing environment-friendly gloves

A production method and glove technology, applied to gloves, clothing, clothing, etc., can solve the problems of waste of materials and low production efficiency, and achieve the effects of high production efficiency, cloth material saving, and simple and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

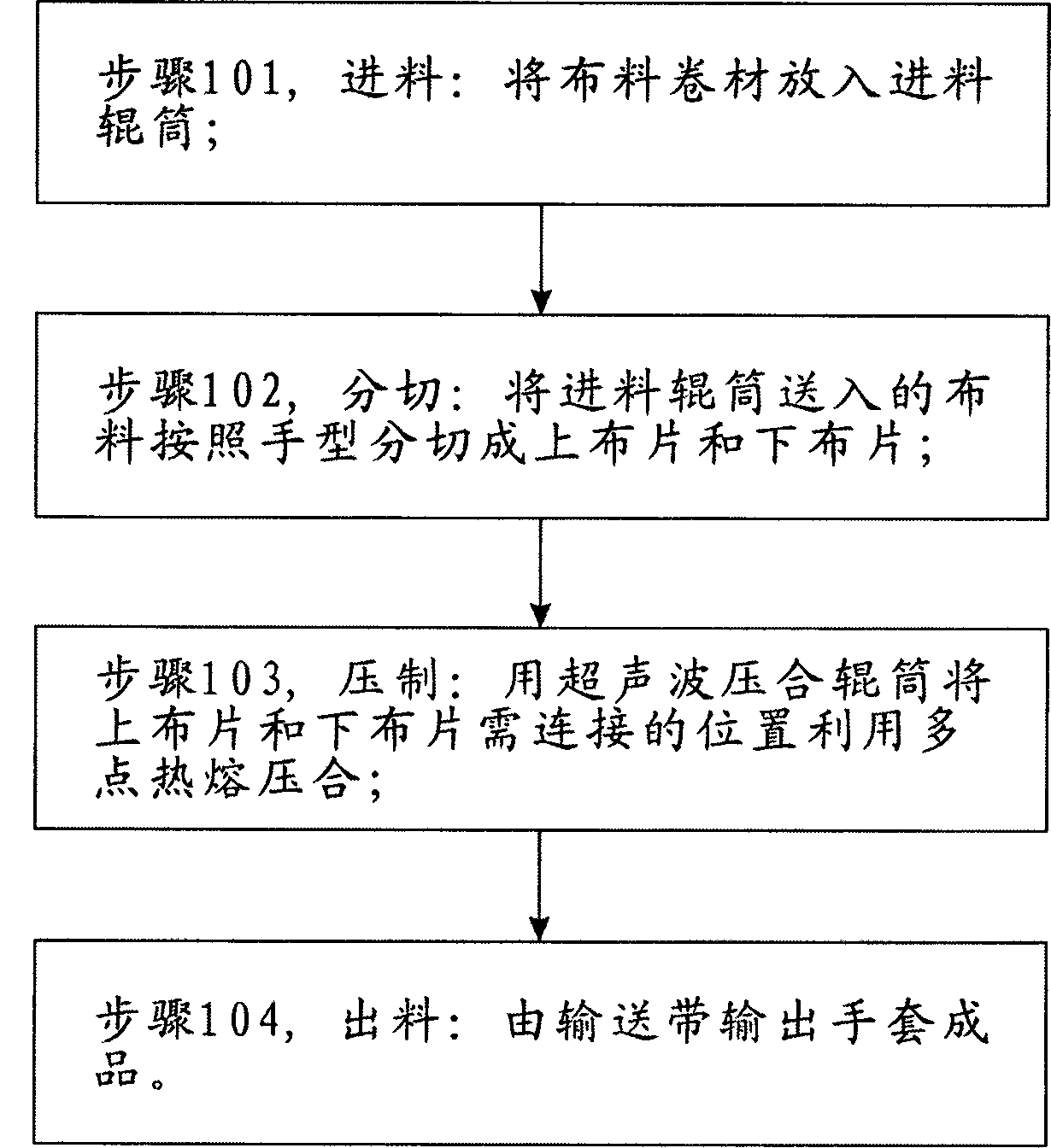

[0015] see figure 1 , the manufacture method of environment-friendly gloves of the present invention, comprises the following steps:

[0016] Step 101, feeding: putting the cloth roll into the feeding roller;

[0017] Step 102, cutting: cutting the cloth fed by the feed roller into upper cloth pieces and lower cloth pieces according to the hand shape;

[0018] Step 103, pressing: using an ultrasonic pressing roller to bond the upper cloth piece and the lower cloth piece to be connected by multi-point hot-melt pressing;

[0019] Step 104, output: the finished glove is output by the conveyor belt.

[0020] Wherein, after the discharging step, it also includes:

[0021] Step 105, packing: packing into bags according to the standard of 12 pairs of gloves / bag.

[0022] Wherein, in the pressing step 103 , the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com