Escape sliding cable between floors

A zipline and building technology, which is applied in the field of escape ziplines between buildings, can solve problems such as waiting for death, and achieve the effects of simple production, obvious effect, and increased escape opportunities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

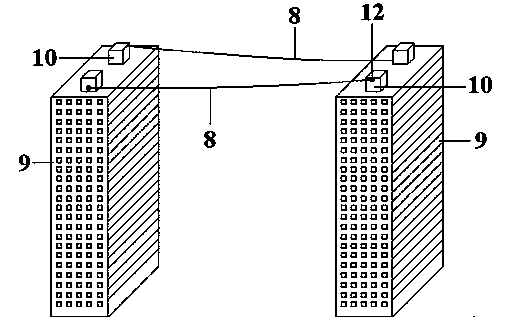

[0014] Embodiment 1. An escape rope between buildings, which is characterized in that it consists of a rope (8), a building body (9), a roof protrusion (10), and a fixed point (12). At least two roof projections (10) are provided, and the projections (10) are provided with zipline fixed points (12), respectively connected to the ziplines on the roof projections (10) on the opposite building body (9). The fixed points (12) are connected by ziplines (8), and each zipline (8) is installed obliquely, forming a 2-3 between the two zipline fixed points (12) of each zipline (8). height difference in meters.

Embodiment 2

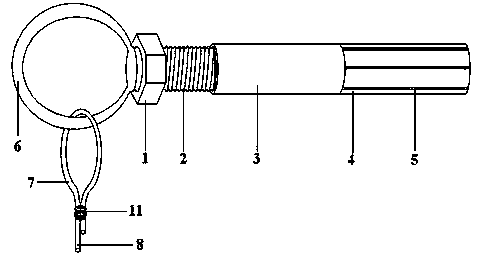

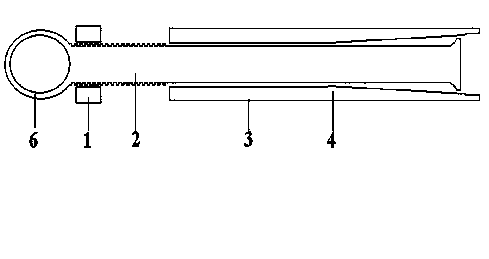

[0015] Embodiment 2, to further limit Embodiment 1, the fixed point (12) of the zip line is an expansion screw, and the expansion screw includes a nut (1), a screw rod (2), an expansion solid cylinder (3), and an expansion cylinder wall (4) . Expansion cylinder wall crack (5), nut (1) has a hexagonal outer side, a round center, and internal thread, which meshes with the thread on the screw rod 92. The screw rod (2) includes a threaded section and a non-threaded section 1. There are three parts of the expansion rod head, the expansion solid cylinder (3) is the metal cylinder outside the threadless section of the screw rod (2), and the expansion solid cylinder (3) is connected with the expansion cylinder wall (4) to form the screw rod (2) The front and rear parts of the outer structure have the same outer diameter. The wall thickness of the expansion cylinder wall (4) gradually increases from front to back, and the expansion cylinder wall cracks (5) are cracks in the expansion c...

Embodiment 3

[0016] Embodiment 3 is further limited to Embodiment 2. The screw rod (2) has a wire end ring (6) at the outer end of the wire section, which is used to connect the cable end ring (7), and the cable end ring (7) is a zip line (8 ) after passing through the wire end loop (6) and fixing it with the cable end wire (11) to form a structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com