Heterogeneous catalysis wet oxidation catalyst taking volcanic rock as carrier and preparation method thereof

A heterogeneous catalysis and wet oxidation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low COD removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Immerse 1.98g of volcanic rock in 0.052g of RuCl 3 in solution. Impregnated at room temperature for 6h, then dried in an oven at 110°C for 16h, then calcined in a muffle furnace at 450°C for 5h to obtain the catalyst precursor, and finally reduced with hydrogen at 400°C for 4h to obtain the finished catalyst.

[0022] In the foregoing examples, the same evaluation conditions for heterogeneous catalyzed wet oxidation reactions are:

[0023] Reactor: fixed bed reactor, inner diameter 22 mm, reactor length 800 mm

[0024] Filling volume: 300ml

[0025] Reaction temperature: 290°C

[0026] Reaction pressure: 9.0MPa

[0027] Industrial organic wastewater COD: 15000mg / l

[0028] Gas-liquid volume ratio: 150

[0029] The COD value of the reaction product was measured with a COD analyzer from Hach Company. The COD value of the organic industrial wastewater after the reaction was measured to be 975mg / l, and the COD removal rate was 93.5%.

[0030]

Embodiment 2-4

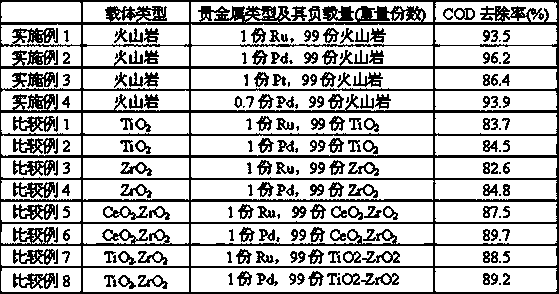

[0032] The steps in Examples 2-4 are the same as in Example 1, except that the type and load of the noble metal are different. The specific conditions and results are listed in Table 1.

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com