Separating screen with automatic cleaner

An automatic cleaning and sorting screen technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problem of unable to clean the screen, and achieve the effect of improving sorting efficiency, improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

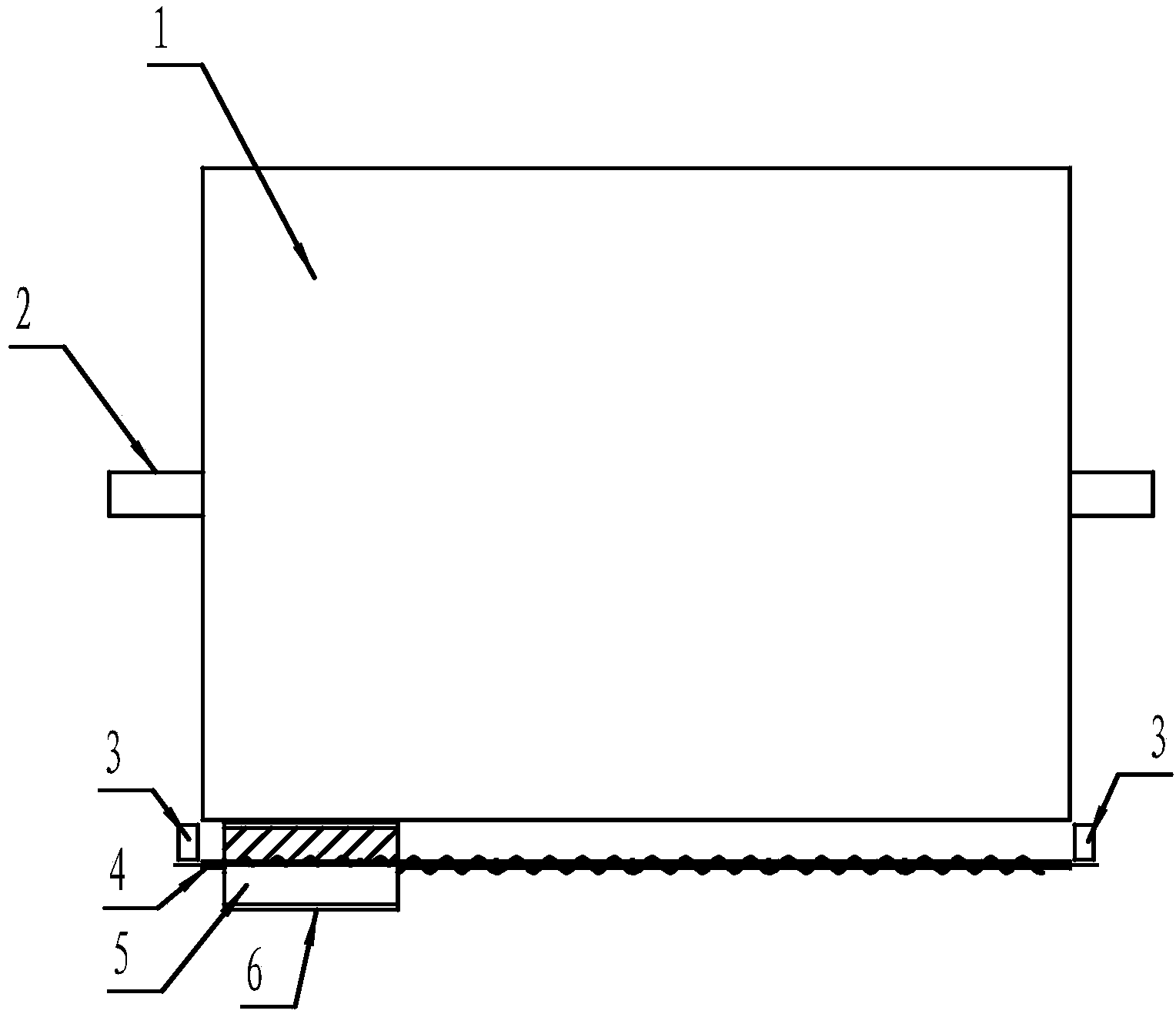

[0013] Embodiment 1, a sorting screen with an automatic cleaning device, including a cylindrical sorting screen 1 that rotates around the sorting screen shaft 2, is characterized in that: the sorting screen is equipped with a sorting screen A lead screw shaft 4 parallel to the busbar is installed on the lead screw shaft, and a cleaning brush closely contacting with the surface of the sorting screen is installed on the screw shaft. Reversing switches 3 are respectively provided at both ends of the sorting screen close to the side of the screw shaft. When traveling to both ends, they can be in contact with reverse switches respectively.

[0014] The cleaning brush is composed of a cleaning brush core body 5 with an internal thread matched with the lead screw thread in the center and a steel wire bristle 6 fixed on the outer surface of the cleaning brush core body.

Embodiment 2

[0015] Embodiment 2, a sorting screen with an automatic cleaning device, including a conical cylindrical sorting screen 1 that rotates around the sorting screen shaft 2, is characterized in that: the sorting screen is equipped with a sorting screen A lead screw shaft 4 parallel to the busbar is installed on the lead screw shaft, and a cleaning brush closely contacting with the surface of the sorting screen is installed on the screw shaft. Reversing switches 3 are respectively provided at both ends of the sorting screen close to the side of the screw shaft. When traveling to both ends, they can be in contact with reverse switches respectively.

[0016] The cleaning brush is composed of a cleaning brush core body 5 with an internal thread matched with the lead screw thread in the center and a steel wire bristle 6 fixed on the outer surface of the cleaning brush core body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com