A device for efficiently removing the weld reinforcement of composite stainless steel pipes

A technology for stainless steel pipe and weld excess height, which is applied in driving devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems of poor removal quality, high cost and low removal efficiency, and achieve low cost and high work efficiency. , the effect of cutting quality is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

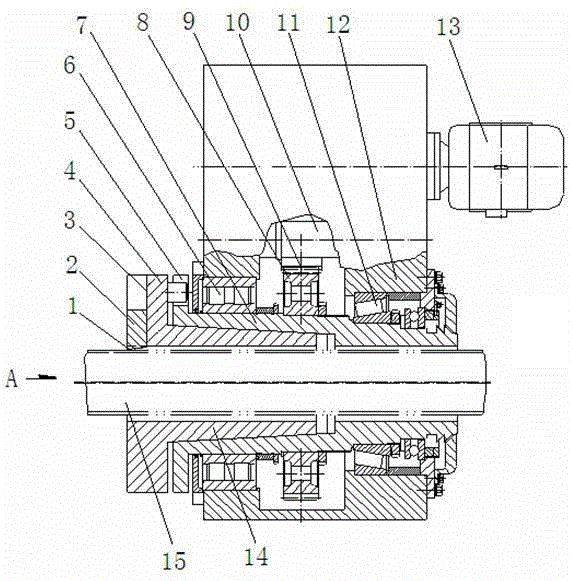

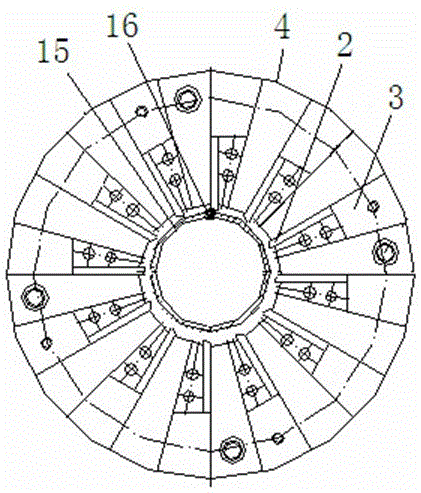

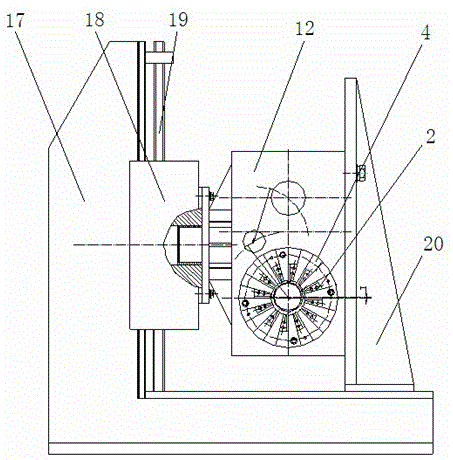

[0016] The device for efficiently removing the weld reinforcement of composite stainless steel pipes provided by the present invention includes a support 12, a power machine arranged on the support 12, and the power machine includes a motor 13, a reduction box and an output spindle 10, wherein: the output shaft 10 of the power machine passes through The transmission assembly is connected to the cutter shaft 14 with a cutter head 4 at the outer end and a shaft hole in the center. The cutter head 4 is provided with a cutter 2, and twelve grooves 3 are arranged at intervals on the surface of the cutter head 4, and each groove 3 is arranged radially along the disk surface, and a cutter 2 is fixed in each groove 3 by fixing nails, and the blade 1 of the cutter 2 extends toward the shaft core, so as to adjust the radial position of the cutter 2 in the groove 3 as required, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com