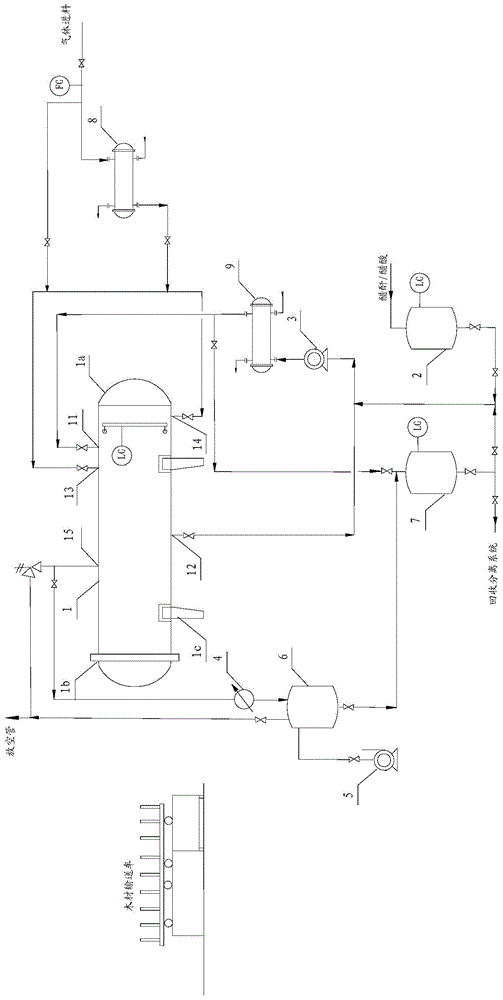

A device system and process for wood acetylation production

A production process and acetylation technology, which is applied in the device system and process field of wood acetylation production, and can solve the problems of separation, difficulty in recycling, long drying cycle, and low qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] (1) Take 30 pieces with the specification of 2000mm×200mm×30mm (longitudinal×chord direction×radial direction) (the density is 0.56g / cm 3 ), larch boards with a moisture content of 10wt% (total volume 0.5m 3 ) are neatly stacked in the wood transport vehicle, then sent into the high-pressure acetylation tank 1, and the reaction tank is sealed; then the gas outlet 15 valve on the high-pressure acetylation tank 1 is opened, the vacuum pump 5 is turned on, and vacuum is started to make the high-pressure acetylation The inside of tank 1 reaches -0.09MPa and keeps for 60min;

[0092] (2) Inject the two streams of acetic anhydride and acetic acid into the ingredient storage tank 2, stir and mix evenly to form an acetylation reaction liquid, in which acetic acid accounts for 15wt% and acetic anhydride accounts for 85wt%; close the gas outlet of the high-pressure acetylation tank 1 15 valve, stop vacuuming, open the reaction liquid inlet valve 11 of the high-pressure acetylati...

Embodiment 2

[0098] (1) 24 pieces with a specification of 2000mm×150mm×40mm (longitudinal×chord×radial) and a density of 0.39g / cm 3 , poplar board with a moisture content of 8wt% (total volume 0.4m 3 ) are neatly stacked in the wood transport vehicle, then sent into the high-pressure acetylation tank 1, and the reaction tank is sealed; then the gas outlet 15 valve on the high-pressure acetylation tank 1 is opened, the vacuum pump 5 is turned on, and vacuum is started to make the high-pressure acetylation The inside of tank 1 reaches -0.05MPa, keep it for 100min;

[0099] (2) Close the gas outlet 15 valve of the high-pressure acetylation tank 1, and stop vacuuming; open the reaction liquid inlet 11 valve of the high-pressure acetylation tank 1, the liquid outlet valve of the ingredient storage tank 2, and the branch outlet valve of the mother liquor collection tank 7 B, then turn on the liquid delivery pump 3 to mix the acetylation reaction liquid formed by mixing the acetic anhydride in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com