Application and method of pattern definition system for manufacturing stone imitating pattern ceramic product

A technology of ceramic products and patterns, applied to the application and field of pattern forming systems in making ceramic products with imitation stone patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

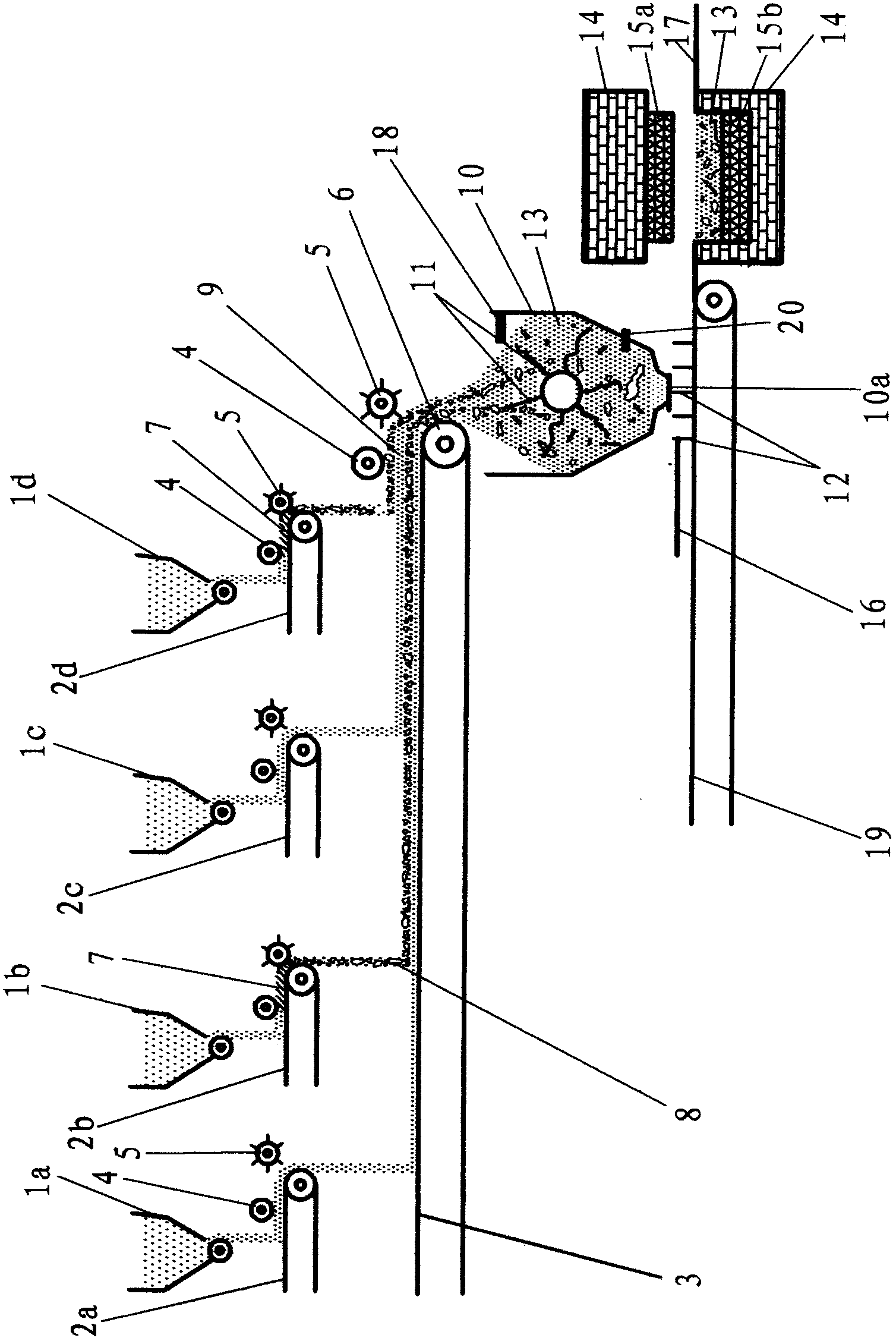

[0052]The following describes the application of prefabrication and stirring formation in the manufacture of stone-like pattern ceramic products and the process of the method according to the embodiment of the present invention.

[0053] see figure 1 As shown, it is an application example of prefabrication and stirring shaping of the present invention in making ceramic products with imitation stone patterns, which uses a belt to drop multi-layer prefabricated porcelain raw materials of different shapes with predetermined colors into the stirring device. And the product mixed raw material cloth formed by predetermined agitation falls into the feeding carrier and then sent to the press forming device for forming. It can be seen from the figure that the labels 1a, 1b, 1c, and 1d indicate the silos; the labels 2a, 2b, 2c, and 2d indicate the auxiliary belts for receiving and sending raw materials under the predetermined rollers; The predetermined adjustable thickness-limiting rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com